China Geotextile Bag Plastic Grass Grid for Land Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

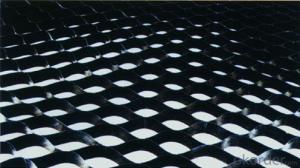

1,Description of Plastic Grass Grid

Nature Planting grass grid using modified high molecular HDPE as raw materials , Green and Environmental Protection , Completely recyclable , it can perfect realize to combine the lawn and parking lot,it can bear pressure , abrasion resistance, impact resistance, antiaging, corrosion resistance , improve the quality , and save the investment; unique flat plug type overlap joint , improve work efficiency and quick install , can adjust expansion joint .

Material : Modified high molecular HDPE , Fiberglass , Nanometer oxide , Coloring Material ( standard ratio) .

Color : green color or other any specified color

Bearing capacity : The hightest 200T/m2

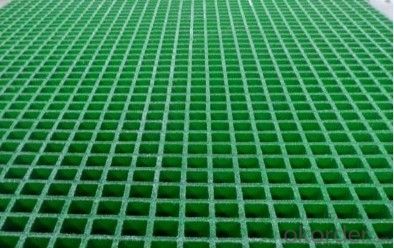

2,Specialities of Plastic Grass Grid

1) High strength , long life service .

2)Nature Planting grass grid use special material with patent technology , maximum stress tolerance can meet 200T/m2 , greater than 32T/m2 for standard requirement fire fighting high surface .

3) Stable performance , anti-UV , resistance to acid and alkali corrosion , anti-wear and pressure , anti-temperature -40°C-90°C. (Reference : concrete planting grass brick will be easy to craze and damage when temperature variation ) .

4) Good drainage .

5) Gravel bearing layer provides good drainage function , so that easy to drain excessive rainfall .

6) Lap joint . flat plug type overlap joint , very convenient , arbitrarily adjust expansion joint width , to fit temperature change

3, Application of Plastic Grass Grid

Parking lot , Fire fighting access , Fire fighting high surface , Golf lane , Conference and exhibition center , Modern workshop , Upscale community , Roof garden and so on .

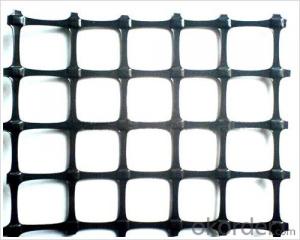

4,Construction suggestions:

Foundation soil should be compaction as different layers , Compactness should be reach more than 85% .

Gravel bearing should be paved 350 thickness (Fire lane should be 600 thickness) , spread out to flat and grind to compaction .

Gravel or coarse sand should be paved 20thickness .as the flat layer .

Pave and install grass grid can be cut to suitable size by saw , and you should leave a few millimeters slit between grid and grid .

Sowing planting soil on the grid surface from the top about 1.0cm

Lay down in grass or sowing grass seed . While lay down in grass , .turfing has to be compacted , watering and maintaining , you can park car when grass grow .Protecting lawn .

Gravel bearing layer can supply some store water function , this is beneficial for lawn grow , grass roots can grow to gravel layer .(Reference: concrete planting grass brick only has small space , and when under summer sunshine , temperature will reach more than 50 °C ) .

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of construction materials, including but not limited to PP staple fiber, geotextile geo-grid, geo-bag etc. Customized product is also available based on your detailed requirements.

2>How long can we receive the product after purchase?

It takes about 1 to 4 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: How do geotextiles contribute to soil consolidation?

- Geotextiles contribute to soil consolidation by providing reinforcement and stabilization to the soil. They act as a barrier between different soil layers and help distribute the loads evenly, reducing the risk of soil movement and settlement. Additionally, geotextiles can improve soil drainage and filtration, allowing excess water to flow through while retaining the integrity of the soil structure. Overall, geotextiles play a crucial role in enhancing soil consolidation and providing long-term stability to construction projects and civil engineering applications.

- Q: What are the different geotextile installation techniques for roadways?

- There are several geotextile installation techniques for roadways, including overlay installation, trench installation, and full-depth installation. Overlay installation involves placing the geotextile on top of the existing road surface before applying a new layer of asphalt or other material. Trench installation involves placing the geotextile in a trench dug along the road's edge and backfilling it with soil or aggregate. Full-depth installation involves placing the geotextile directly beneath the entire road structure, providing reinforcement and separation between the subgrade and the overlying layers. The choice of technique depends on the specific road construction requirements and the desired benefits of using geotextiles.

- Q: Weaving geotextile construction should pay attention to what

- Weaving geotextile construction specifications: 1, before the construction of roadbed should be integrated clean up, the surface shall not have sharp corners. 2, geotextile is best to use mechanical erection, can also be used artificial laying. When laying, it should be noted that the rough side of the singeing up, and then one end fixed with a fixed, mechanical or human tension, tensile elongation of about 1 & amp;% to 1 & amp;%, Facing front laying. The fixture includes fixed and fixed metal. Fixed nails should be used cement nails or nails, nail length 8 ~ 10cm fixed iron can be thick lmm, width 3mm of the strip. 3, weaving geotextile and the length of the long, should be used industrial sewing machine sewing, sewing method using "dow" and "seam". Suture and geotextile should have a significant color difference in order to facilitate inspection.

- Q: How do geotextiles contribute to soil reinforcement in embankments?

- Geotextiles contribute to soil reinforcement in embankments by providing a strong and stable base for the soil. They act as a barrier, preventing the migration of soil particles and reducing soil erosion. Geotextiles also enhance the overall stability of the embankment by distributing loads and reducing the risk of slope failure.

- Q: What are the different geotextile installation techniques for steep slopes?

- There are several geotextile installation techniques that can be used for steep slopes. Some of the common techniques include slope stabilization with geotextile mats or grids, slope reinforcement with geotextile wraps or anchors, and soil erosion control with geotextile blankets or erosion control mats. Each technique is chosen based on the specific requirements of the slope and the desired outcome.

- Q: What is the specific use of geotextile construction site? How much is it used?

- Hello, play the role of reinforcement, the use of the filter depends on the design requirements is calculated by square method Huazhi geotextile material manufacturers for you to answer

- Q: How do geotextiles reduce hydraulic pressure in soil?

- Geotextiles reduce hydraulic pressure in soil by allowing water to flow through them, while retaining soil particles. This helps to create a drainage pathway, preventing water buildup and reducing the pressure exerted on the soil.

- Q: Are geotextiles resistant to extreme weather conditions?

- Yes, geotextiles are designed to be resistant to extreme weather conditions. They are manufactured using high-quality materials that can withstand harsh weather elements such as heavy rains, strong winds, and intense sunlight. Geotextiles are specifically engineered to provide long-lasting performance and durability even in extreme weather conditions.

- Q: Can geotextiles be used in dam construction?

- Yes, geotextiles can be used in dam construction. Geotextiles are commonly used in dams as they provide reinforcement, filtration, and drainage functions. They help in stabilizing the soil, preventing erosion, and improving the overall strength and performance of the dam structure.

- Q: What is geotextile, what role

- Geotextile is a new type of building materials, raw materials are polyester, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. Geotextile with anti-seepage, anti-filtration, drainage, isolation, reinforcement, protection, sealing and other functions, it with the conventional masonry and concrete material seepage effect compared to a low investment, simple construction process, short duration Infiltration effect is good, the channel effective use of high coefficient. Water conservancy engineering dams and slope protection filter, channel isolation, seepage control; road, railway, airport runway foundation isolation, filter, drainage, slope, retaining wall and road reinforcement, drainage; , Geotextile has been widely used in the field of infrastructure construction, and has been gradually applied in the field of infrastructure construction, and the use of geotextile In a wider area.

Send your message to us

China Geotextile Bag Plastic Grass Grid for Land Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords