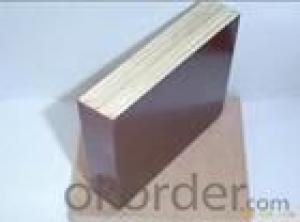

Phenolic Glue Commercial Plywood for 18mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

Detailed Product Description | ||

Place of origin | Shandong China | |

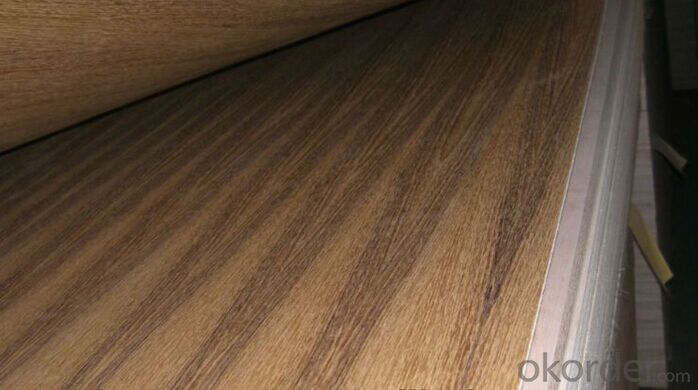

Face&back | Okoume, Bintangor, Pencil Cedar, Keruing, Poplar, Birch, Pine, Maple, Hardwood, Ash, Oak and as your requested | |

Core | Poplar, Hardwood, Hardwood, Combi, Birch, eucalypts, as your requirement. | |

Size | 1220*2440/1250*2500mm and as your requirement | |

Thickness | 2mm to 30mm and as for your requirement | 1/8 inch(2.7-3.6mm) |

1/4 inch(6-6.5mm) | ||

1/2 inch(12-12.7mm) | ||

5/8 inch(15-16mm) | ||

3/4 inch(18-19mm) | ||

Thickness tolerance | 2-6mm: +/-0.2mm | |

6-30mm: +/-0.3mm | ||

Grade | BB/BB, BB/CC, CC/CC, CC/DD,DD/EE, etc. | |

Glue | MR,E1,E2,Melamine,WBP Phenolic | |

Moisture | 10%-15% | |

Joint way | Overlap joint, end joint, scraf joint, finger joint | |

Strength | High bending strength Strong nail holding | |

Quantity | 8 pallets/20ft,16 pallets/40ft,18 pallets/40HQ | |

Usage | construction, Furniture, decoration, packing. | |

Certificate | ISO9001: 2000; CE; CARB | |

Main market | Middle East, South Asia, South America, Africa | |

Shipment & payment | ||

MOQ | One container | |

Port | Qingdao | |

Packing details | Inner packing: 0.2mm thick plastic bag Outer packing: pallets covered with plywood/carton, then steel taped for strength | |

Delivery time | 2 weeks after your deposit | |

Payment | T/T, 30% deposit, the balance against the copy of B/L, L/C at sight. | |

Advantage | ||

Capacity: 6000 CBM per month | ||

Sample available | ||

high quality and competitive price | ||

10 years’ experience in export | ||

Film Faced Plywood :

1.ISO9001:2008;CE;CARB

2.Face/Back: Black/brown/red/anti-slip film

3.Glue:E0,E1,E2,MR

4.Size:1220*2440/1250*2500mm

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: 10 cm thick stainless steel rock wool sandwich board how much money? Both sides have a stainless steel plate in the middle is 10 cm rock wool, the price how to count? How much money?

- 5 cm is about 30 yuan / square 10 cm should not exceed 50 yuan / square

- Q: I would like to buy some sandwich panels, I do not know where the quality is better?

- Aisha Yili's products are good. Quality assurance, you can 30 days unconditional return policy. And the service attitude is also very good. Style is very novel, adequate inventory. There are tens of thousands of models, the product will be weeks on the new,

- Q: How to calculate the amount of steel wool sandwich panel

- According to the top area.

- Q: The foam sandwich panels of the insulated chicken coop are burned! How to do hollowing out?

- Specific solutions: 1 to reduce the brine wave degrees; 2 Add GX-1 # Magnesium Modifier; 3 to do a good job of ventilation and cooling work.

- Q: Color steel plate, color steel sandwich panels, clean color steel plate is the same thing? How much is the price?

- Color plate is veneer 0.4 mm about 23 yuan sandwich panel is a double color plate in the middle plus benzene plate on the 0.3 0.2 is about 45 yuan purification board is used in pharmaceutical plants, food purification plant hanging shed wall panels clean plate surface smooth The price is also expensive and more critical is what you want to do

- Q: Color steel sandwich board how much money

- First, the color plate model: roof? Wall? ?????? Second, the core material (glass wool? Rock wool? Polyurethane? Polyphenylene extrusion), thickness, density ?????? Third, the color plate thickness, origin, coating, plating (aluminum) zinc content ?????? Fourth, the amount will also affect the price to a certain extent.

- Q: How is the ceiling of the residential sandwich panel under the roof?

- Method is to use the form of flat ceiling, the top of the pipeline blocked in the ceiling, the top can be embedded in the downlight or built-in fluorescent lamp, so that the top of the decoration after the formation of two levels, will not produce a sense of depression. Shaped ceiling with a cloud-like wave or irregular arc, generally not more than one-third of the overall top area, more or less than this ratio, it is difficult to achieve good results.

- Q: I need to install a circuit breaker and a few outlets on a container made with sandwich panels.Are there any special equipments or materials for the job?

- You will need to use surface mount materials that can be screwed or bolted to the sandwich panels. Most electrical distribution centers have surface mounting options. For wiring, you will need to use conduit (PVC, EMT, or flex), metal clad cable, or wire mold. Surface mount junction boxes for devices need to be compatible with your choice of wiring method.

- Q: Color steel sandwich board glue is a mixture of vinyl and white plastic, resulting in a chemical reaction caused by sticky. Does anyone know the chemical name of black gelatin? Vinyl are basically imported, and that how is the deployment of white plastic? Is the sandwich used in the sandwich plate diluted? That color steel PU foam with the glue is not the same black and white glue generated reaction? Hope to receive professional mention.

- Black material for the rough MDI grade 5005 44V20 which PM200 for domestic and so on. White materials are mostly phthalic anhydride polyester polyols and dichloromethane solvents and catalyst additives.

- Q: With a foam sandwich board made a 72 flat house, the cheapest how much money

- It depends on how high your house, the color plate is calculated by the board area, calculate the material about 90 or so per square

Send your message to us

Phenolic Glue Commercial Plywood for 18mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords