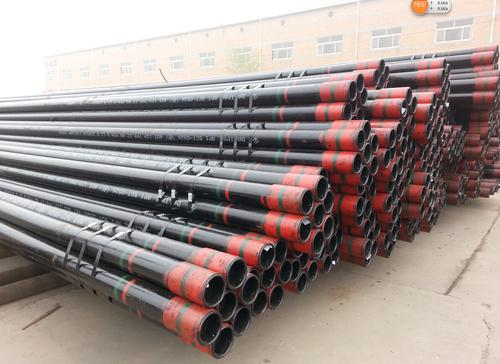

petroleum casing pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000ton m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

API 5CT OIL CASING PIPE

Catalog:Oil Pipes

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: What is the difference between nominal and actual pipe size?

- Nominal pipe size refers to the designation used to identify the approximate inside diameter of a pipe, while actual pipe size refers to the measured inside diameter of a pipe. The nominal size is a standardized value, whereas the actual size may vary slightly due to manufacturing tolerances.

- Q: Can steel pipes be used for conveying chemicals?

- Steel pipes are capable of conveying chemicals. Steel, being a robust and long-lasting material, can endure high pressure and temperature conditions. This makes it suitable for the transportation of diverse chemicals. Moreover, steel pipes possess exceptional resistance against corrosion, which is particularly crucial when handling corrosive substances. They find common usage in industries such as oil and gas, chemical processing, and water treatment, where the secure and efficient conveyance of chemicals is indispensable. However, it is essential to consider the specific requirements of the chemical being transported and ensure compatibility with the steel pipe. It may be necessary to select the appropriate material, including the utilization of corrosion-resistant coatings or linings, to prevent any adverse reactions between the chemicals and the steel pipe.

- Q: How do steel pipes handle water erosion?

- Steel pipes handle water erosion well due to their inherent strength and durability. The smooth surface of steel pipes helps to minimize friction and reduce the potential for erosion. Additionally, the corrosion-resistant nature of steel prevents rusting, ensuring long-term protection against water erosion.

- Q: Can steel pipes be insulated for thermal efficiency?

- Yes, steel pipes can be insulated for thermal efficiency. Insulating steel pipes helps to reduce heat loss or gain, ensuring better energy efficiency and cost savings. The insulation material, such as foam or mineral wool, is typically wrapped around the pipe to create a barrier that minimizes heat transfer.

- Q: Are steel pipes suitable for use in pharmaceutical industries?

- Yes, steel pipes are suitable for use in pharmaceutical industries. They are commonly used in pharmaceutical manufacturing processes as they offer excellent corrosion resistance, durability, and cleanliness. Additionally, steel pipes can withstand high pressure and temperature conditions required for sterilization and the transportation of various pharmaceutical liquids and gases.

- Q: What are the different methods of joining steel pipes together?

- There are multiple techniques for connecting steel pipes, each with its own pros and cons. 1. Welding, the most commonly used method, involves heating and applying pressure to fuse the pipe ends. This creates a robust joint, but it necessitates skilled labor and specialized equipment. 2. Threaded connections involve threading the ends and using fittings to connect the pipes. This method is relatively simple and quick, but it may not be as strong as welding and can be prone to leakage if not sealed properly. 3. Flanged connections involve using flanges and bolts to connect the pipes. This allows for easy disassembly and reassembly, making it suitable for applications that require frequent maintenance. Flanged connections are also highly resistant to leakage. 4. Compression fittings involve compressing a ring or ferrule onto the pipe to create a tight seal. This method is straightforward and does not require heat or welding, making it ideal for applications where heat or sparks are prohibited. 5. Grooved connections involve cutting grooves into the pipe ends and using mechanical couplings to secure them. This method is fast, reliable, and allows for easy assembly and disassembly. Grooved connections are commonly used in fire protection systems. 6. Brazing, similar to welding, involves heating the pipe ends and adding filler material to join them. This method is often used for smaller diameter pipes and provides a strong joint, but it requires a high-temperature torch and skilled labor. Each method has its own advantages and is suitable for different applications. The choice of joining method depends on factors such as required strength, ease of installation, maintenance requirements, and pipe type.

- Q: How are steel pipes used in the construction of coal-fired power plants?

- Steel pipes are commonly used in the construction of coal-fired power plants for various purposes. They are utilized for transporting coal and other fuels, as well as for carrying water and steam in the power generation process. Steel pipes are also used in the construction of the plant's cooling system, helping to circulate water and dissipate heat. Additionally, they are employed in the construction of the plant's exhaust system, facilitating the removal of combustion byproducts. In summary, steel pipes play a crucial role in the infrastructure of coal-fired power plants, enabling efficient fuel transportation, heat exchange, and waste management.

- Q: Can steel pipes be used for underground drainage?

- Yes, steel pipes can be used for underground drainage. Steel pipes are commonly used in underground drainage systems due to their durability, strength, and resistance to various environmental factors. They are able to withstand heavy loads, pressures, and corrosion, making them suitable for long-term underground drainage applications.

- Q: What kinds of steel pipe are divided into?

- According to the weld shape can be divided into longitudinal welded pipe and spiral welded pipeStraight welded pipe: the production process is simple, high production efficiency, low cost, rapid developmentSpiral welded pipe: strength ratio of longitudinal welded pipe is high, with a narrow billet production of large diameter pipe, also can use the blank production of the width of the same diameter of different pipe. But with the same length of straight pipe, weld length of 30~100%, and the production rate is low. Therefore, the smaller diameter pipe most used straight large diameter pipe welding, mostly using spiral welding.Dividedagain general welded pipe, galvanized pipe, blowing pipe, wire tube, pipe metric, roller tube, deep well pump, tube for automobile, transformer tube, welding, welding of thin-walled tube shaped tube and spiral welded pipe.General general pipe: pipe used for conveying the low-pressure fluid. Q195A, Q215A and Q235A made of steel. Also can be used for easy welding of mild steel. The other pipe to conduct water pressure, bending and flattening test, have certain requirements on the surface quality, usually the delivery length is 4-10m, often requires a fixed length (or size) of delivery. The specifications of welded pipe with nominal diameter (mm or inches) nominal diameter and different pipe wall thickness, according to the provisions of general steel and thicker steel two, steel pipe end is divided according to form of threaded and non threaded two.

- Q: What are the advantages of using steel pipes over other materials like PVC or copper?

- There are several advantages of using steel pipes over other materials like PVC or copper. Firstly, steel pipes are incredibly durable and can withstand high pressure and extreme temperatures, making them suitable for various industrial applications. They are also resistant to corrosion, ensuring a longer lifespan compared to PVC or copper pipes. Additionally, steel pipes have excellent structural strength, providing enhanced stability and safety. They are also environmentally friendly as they can be recycled, reducing their impact on the environment. Overall, steel pipes offer superior strength, longevity, and reliability, making them a preferred choice for many industries.

Send your message to us

petroleum casing pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000ton m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords