Perforated Casing Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

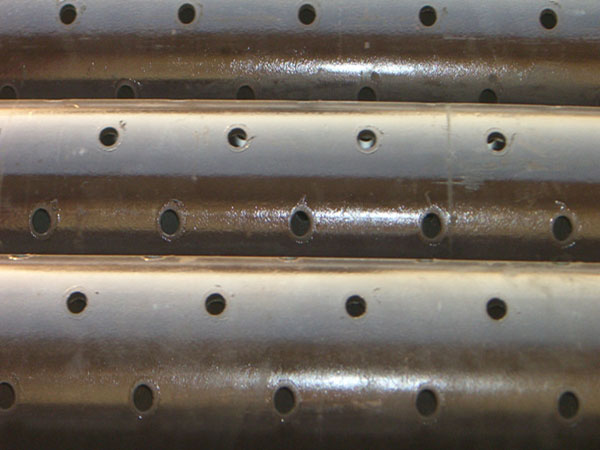

Product Descriptions :N80 Perforated Casing Pipe

1.The Perforated pipe uses J55 or N80 oil casing as the processing body. This ensures high strength and no distortion.

2.The hole is uniform,smooth,and has no burr.

3.The overall anticorrosive processing results in a dense protective layer on the surface of screen pipe,so as to improve its corrosion and wear resistance,and effectively prolong the downhole working life.

4.The perforated pipe comes with simple use. due to big inside diameter,it also brings convenience for pipe string sonfiguration.

5.The type of hole can be freely selected by the customer.

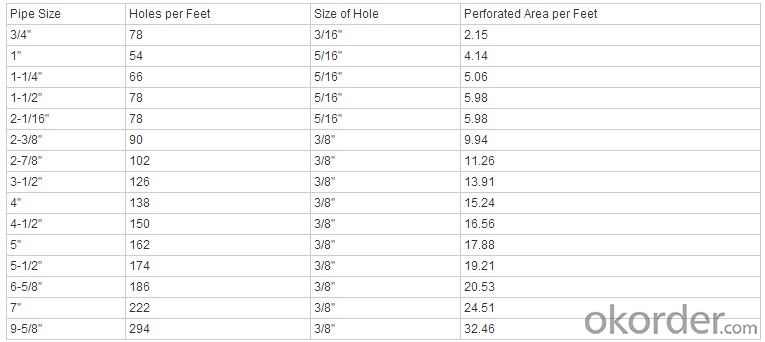

Technical Parameters

Dalipal Company is one of the most famous enterprises of china professionally producing pipeline and oil casing.We can supply API 5CT series of pipeline and oil casing with all kinds of specifications and materials.We have first-class production equipment and technology.

- Q: Can steel pipes be used for the construction of high-rise buildings?

- Yes, steel pipes can be used for the construction of high-rise buildings. Steel pipes offer several advantages such as high strength, durability, and resistance to fire, making them a suitable choice for supporting the structural load and ensuring the stability of tall structures. Additionally, steel pipes can be easily fabricated and installed, providing flexibility in design and construction.

- Q: Are steel pipes fire-resistant?

- Yes, steel pipes are generally fire-resistant. Due to their high melting point and low flammability, steel pipes can withstand high temperatures and prevent the spread of fire.

- Q: Can steel pipes be used for oil wells?

- Yes, steel pipes can be used for oil wells. Steel pipes are highly durable and resistant to corrosion, making them suitable for the harsh conditions and high-pressure environments encountered in oil drilling operations.

- Q: What are the different types of steel pipe flanges?

- There are several types of steel pipe flanges, including slip-on flanges, weld neck flanges, socket weld flanges, threaded flanges, blind flanges, and lap joint flanges. Each type has unique features and is used in specific applications based on factors such as pressure ratings, pipe size, and end connections.

- Q: What are the different types of steel pipe supports for high-temperature applications?

- Some different types of steel pipe supports for high-temperature applications include hangers, clamps, brackets, and anchors. These supports are designed to withstand the elevated temperatures and provide stability and proper alignment to the piping system.

- Q: How are steel pipes used in the construction of irrigation systems?

- Steel pipes are commonly used in the construction of irrigation systems due to their strength and durability. These pipes are used to transport water from a water source, such as a well or reservoir, to the desired areas for irrigation. They are often used in underground or above-ground applications, providing a reliable and efficient means of delivering water to crops or plants. Steel pipes are resistant to corrosion and can withstand high pressure, making them ideal for irrigation systems that require long-term functionality.

- Q: Are metal spiral tubes the same as metal bellows?

- Hello. The two are not the same. The difference lies in. The pitch of a spiral pipe is much larger than that of a bellows. The maximum material thickness of the spiral tube is much thicker than that of the bellow. The diameter of a spiral tube can be very large. But the bellows can't be too big in diameter.

- Q: How are steel pipes specified in engineering drawings?

- Steel pipes are specified in engineering drawings by providing information such as the diameter, thickness, material grade, length, and any additional specifications or requirements such as the type of coating or threading needed.

- Q: How are steel pipes protected from damage during transportation?

- Various methods are used to protect steel pipes from damage during transportation. One commonly employed technique involves applying protective coatings to the pipes. Materials like epoxy, zinc, or polyethylene are often used for this purpose, creating a barrier between the pipe and external elements. These coatings effectively prevent corrosion and damage during transit. In addition, steel pipes are frequently bundled together and secured using straps or bands. This bundling ensures that the pipes remain in place and prevents any shifting or rolling during transportation. Furthermore, padding or cushioning materials, such as foam or rubber, may be utilized to provide extra protection and reduce the risk of damage from impact or vibration. Sometimes, steel pipes are placed in crates or containers to provide further safeguarding. Crates are designed to snugly fit the pipes, offering a secure enclosure that shields against external forces. On the other hand, containers create a protective environment for the pipes, shielding them from the elements and potential impacts. To guarantee the safe transportation of steel pipes, proper handling and loading techniques are crucial. Pipes should be lifted and loaded onto transport vehicles with care, utilizing suitable equipment like cranes or forklifts to minimize the risk of damage. It is also essential to properly secure the pipes within the transport vehicle to prevent any movement or potential damage during transit. Overall, a combination of protective coatings, bundling, padding, and secure packaging or loading techniques is employed to ensure the safety of steel pipes during transportation. These measures guarantee that the pipes arrive at their destination in optimal condition, ready for use in various applications.

- Q: Are galvanized steel tubes the same as degaussing steel tubes?

- Also known as galvanized steel pipe, hot galvanized and galvanized two kinds, hot galvanized, zinc coating thickness, with uniform coating, adhesion, and long service life. The cost of galvanizing is low, the surface is not very smooth, and the corrosion resistance of itself is much worse than that of galvanized pipe.

Send your message to us

Perforated Casing Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords