PET Laminated Tinplate Sheets for Cans Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PET Laminated Tinplate Sheets for Cans Use

1.Structure of Description

PET Laminated Tinplate Sheets for Cans Use with golden color is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.We are one of the professional producer for PET laminitad Tinlate coil. At present, ourproductivity is about 100000 MT/year.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

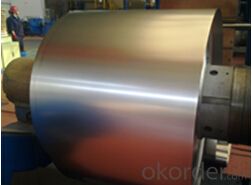

3. Images

4. Specification

Tinplate size:

TEMPER: T1-T5, DR7-9

ANNEALING:BA/ CA

THICKNESS: 0.15~0.45mm

WIDTH: 600~1050mm

Packaging Detail: For coils: Anti-rust paper +metal cover +corner protected +woodskid Laded into 20 feet container with max weight 25 tons;For sheets: Thinplastic film +rust-proof paper +metal cover +metal angles + straps + pallet.Loaded in 20 feet container with weight 25 tons

5.FAQ

The main product tinplate and tin freesteel are metal package material widely used in food, light industry andchemical industry. We organize our production strictly in accordance with Q/ZYBE1、Q/ZYB E3、GB/T252, GB/T24180, JIS G3303, JIS G3315 and ISO11950 or equivalentstandards. Companies adhere to principles of quality, food safety, environment,occupation, health safety and energy, say "excellent quality to win thetrust of customers, health and safety to gain the trust of the public, clean environmentto harvest the trust of the community, safety and health to convince employeesand energy-saving to be trusted by public". We are enjoying the trust andgood name regarding to the superior quality and prefer service among thecustomers. Our products are sold nearly 150 enterprises including Europe,America, Oceania, Middle East and Southeast Asia.

Company management system is healthy, operational mechanism runninggood. After years of effort, base on the introduction, absorption, digestion ofthe advanced technology, techniques, equipment, we gradually set up the uniqueproduction process and technical support system which is market need-orientaland suite to the Chinese condition. In the fierce market competition, ourcompany will continue to pursue the excellence quality and outstanding service,and provide more and better service and service to meet customers demand onmetal package home and abroad.

We has a customer service center whichproviding customers with whole-process service including the pre-sale, sale andafter-service, unified handling customer inquiries and complaints. CustomerService Center adhere to the goal “customer first and response rapidly” andarrange their service work according to the standard procedures. Our commitment:ready to accept advice and customer complaints, reply comments within 24 hoursof treatment, when dealing with customer complaints of quality issues, uponcustomer’s request, sent the inspector to the user site to save problem within24 hours (within the province) and 48 hours (other provinces).

- Q: What are the main applications of tinplate?

- Tinplate is mainly used in the packaging industry for making cans, containers, and other metal packaging products. It provides excellent protection against corrosion, making it suitable for storing and preserving food, beverages, chemicals, and other perishable goods. Additionally, tinplate is also used in the manufacturing of aerosol cans, decorative items, and various other household products.

- Q: What is the shelf life of tinplate canned goods?

- The shelf life of tinplate canned goods can vary depending on the specific product and storage conditions. However, in general, properly stored tinplate canned goods can have a shelf life ranging from 1 to 5 years. It is important to check the expiration date and follow proper storage guidelines to ensure the quality and safety of the canned goods.

- Q: How is tinplate affected by different types of dairy products?

- Tinplate, a type of steel coated with a thin layer of tin, can be affected by different types of dairy products in terms of corrosion. Dairy products, particularly those with high acidity or salt content, can cause the tin coating to corrode over time. This can result in changes in the taste, odor, and quality of the dairy products stored in tinplate containers. Therefore, proper packaging and storage conditions need to be ensured to maintain the integrity of tinplate when storing dairy products.

- Q: How does tinplate perform in terms of corrosion resistance compared to other materials?

- Tinplate performs exceptionally well in terms of corrosion resistance compared to other materials. Its unique composition of steel coated with a thin layer of tin provides a protective barrier against moisture and oxidation, preventing rust and corrosion. This makes tinplate highly suitable for various applications, especially in the packaging industry, where it ensures the preservation and longevity of products.

- Q: What are the different forms and shapes tinplate can be manufactured into?

- Tinplate can be manufactured into various forms and shapes, including cans, containers, boxes, trays, and even decorative items. Its malleability allows for complex designs, making it suitable for a wide range of applications in the packaging industry.

- Q: What are the limitations of printing on tinplate?

- There are several limitations to printing on tinplate. Firstly, tinplate is not a very smooth surface, which can affect the quality of printed images and text. Additionally, the printing process on tinplate requires specialized inks and equipment, making it more costly and time-consuming compared to printing on other materials. Furthermore, tinplate is prone to scratching and chipping, which can damage the printed design. Lastly, the printing options on tinplate are somewhat limited, as it cannot accommodate intricate or highly detailed designs as well as other printing mediums.

- Q: How does the coating affect the properties of tinplate?

- The coating on tinplate plays a crucial role in enhancing its properties. It protects the underlying tin layer from corrosion, making tinplate highly resistant to rust. The coating also provides a barrier against external elements, ensuring the integrity and longevity of the tinplate. Additionally, the coating can improve the appearance of tinplate, making it more visually appealing. Overall, the coating significantly enhances the durability, corrosion resistance, and aesthetic appeal of tinplate.

- Q: What are the main challenges in the tinplate industry?

- The main challenges in the tinplate industry include fluctuating raw material prices, increasing competition from alternative packaging materials, environmental concerns related to tin coating and waste management, and the need for continuous technological advancements to meet evolving customer demands. Additionally, market volatility, trade barriers, and regulatory compliance are also key challenges faced by the tinplate industry.

- Q: How does tinplate perform in terms of durability and longevity?

- Tinplate is highly durable and long-lasting due to its corrosion-resistant properties. It can withstand harsh environmental conditions and is resistant to rust and oxidation, making it ideal for various applications where durability is crucial. Additionally, tinplate's longevity is further enhanced through proper coating and maintenance, ensuring its longevity even in demanding environments.

- Q: How does tinplate packaging contribute to product aesthetics?

- Tinplate packaging contributes to product aesthetics by providing a visually appealing and attractive presentation. The shiny and smooth surface of tinplate enhances the overall look of the packaging, giving it a premium and high-quality feel. Additionally, tinplate allows for intricate designs, embossing, and printing techniques, allowing brands to create eye-catching graphics and logos that further enhance the visual appeal of the product.

Send your message to us

PET Laminated Tinplate Sheets for Cans Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords