PET Laminiated TFS for 0.19mm Thickness Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PET Laminiated TFS for 0.19mm Thickness Sheets

1.Structure of Description

PET Laminiated TFS for 0.19mm Thickness Sheets is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.We are one of the professional producer for PET laminitad TFS. At present, ourproductivity is about 100000 MT/year.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

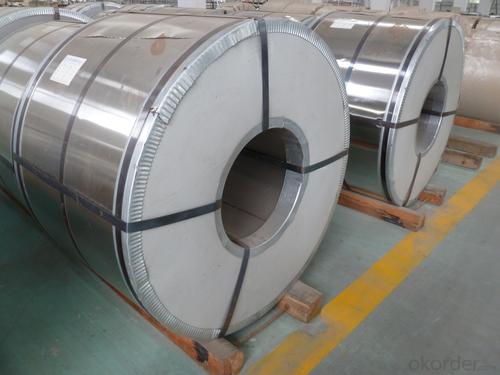

3. Images

4. Specification

TEMPER: T1-T5, DR7-9

ANNEALING:BA/ CA

THICKNESS: 0.15~0.45mm

WIDTH: 600~1050mm

Packaging Detail: For coils: Anti-rust paper +metal cover +corner protected +woodskid Laded into 20 feet container with max weight 25 tons;For sheets: Thinplastic film +rust-proof paper +metal cover +metal angles + straps + pallet.Loaded in 20 feet container with weight 25 tons.

5.FAQ

The main product tinplate and tin freesteel are metal package material widely used in food, light industry andchemical industry. We organize our production strictly in accordance with Q/ZYBE1、Q/ZYB E3、GB/T252, GB/T24180, JIS G3303, JIS G3315 and ISO11950 or equivalentstandards. Companies adhere to principles of quality, food safety, environment,occupation, health safety and energy, say "excellent quality to win thetrust of customers, health and safety to gain the trust of the public, clean environmentto harvest the trust of the community, safety and health to convince employeesand energy-saving to be trusted by public". We are enjoying the trust andgood name regarding to the superior quality and prefer service among thecustomers. Our products are sold nearly 150 enterprises including Europe,America, Oceania, Middle East and Southeast Asia.

Company management system is healthy, operational mechanism runninggood. After years of effort, base on the introduction, absorption, digestion ofthe advanced technology, techniques, equipment, we gradually set up the uniqueproduction process and technical support system which is market need-orientaland suite to the Chinese condition. In the fierce market competition, ourcompany will continue to pursue the excellence quality and outstanding service,and provide more and better service and service to meet customers demand onmetal package home and abroad.

- Q: How does tinplate perform in terms of heat resistance?

- Tinplate has relatively low heat resistance compared to other metals. It can withstand moderate temperatures without warping or melting, but prolonged exposure to high heat can cause it to lose its shape or even melt.

- Q: How does tinplate contribute to the resistance of marine equipment?

- Tinplate contributes to the resistance of marine equipment by providing a protective coating that prevents corrosion and rusting. The tin layer acts as a barrier, shielding the underlying metal from the corrosive effects of saltwater and other environmental factors, thereby increasing the longevity and durability of the equipment in marine environments.

- Q: How does tinplate handle exposure to light?

- Tinplate handles exposure to light quite well. Due to its metallic properties, tinplate is not affected by light in terms of discoloration or degradation. It does not absorb light and is not prone to fading or yellowing. Therefore, tinplate can maintain its appearance and integrity even when exposed to light for extended periods.

- Q: How does tinplate contribute to sustainability efforts?

- Tinplate contributes to sustainability efforts in several ways. Firstly, it is a highly recyclable material, which means that it can be reused multiple times without losing its properties. This helps reduce the demand for new raw materials and minimizes waste generation. Additionally, tinplate is often used as packaging material for food and beverages, providing a protective and durable barrier that extends the shelf life of products, reducing food waste. Furthermore, tinplate cans are lightweight, making them more energy-efficient during transportation, thus reducing carbon emissions. Overall, tinplate's recyclability, protective properties, and energy efficiency make it a sustainable choice for various industries.

- Q: Can tinplate packaging be used for chemical products?

- Yes, tinplate packaging can be used for chemical products. Tinplate is a durable material that provides excellent protection against corrosion and can withstand the harsh conditions often associated with chemical products. Additionally, it is resistant to moisture, light, and oxygen, which helps maintain the integrity and stability of the chemical contents.

- Q: What are the safety regulations for using tinplate in toys?

- The safety regulations for using tinplate in toys may vary depending on the country or region. However, in general, these regulations typically include guidelines for lead content, sharp edges, choking hazards, and other potential risks associated with the use of tinplate in toys. It is important for manufacturers and suppliers to comply with these regulations to ensure the safety of children who use the toys.

- Q: What are the advantages of using tinplate for automotive parts?

- Tinplate offers several advantages for automotive parts. Firstly, it provides excellent corrosion resistance, making it ideal for parts exposed to harsh environmental conditions. Additionally, tinplate offers good formability, allowing for complex shapes and designs, providing flexibility in manufacturing. It also offers high strength and durability, ensuring long-lasting performance and safety. Furthermore, tinplate is lightweight, contributing to improved fuel efficiency and reduced emissions. Lastly, it is a cost-effective material, providing value for money in automotive part production.

- Q: What are the main applications of tinplate in the aerosol industry?

- The main applications of tinplate in the aerosol industry include the production of aerosol cans, which are widely used for packaging and dispensing various products such as paints, lubricants, insecticides, and personal care items. Tinplate cans provide excellent barrier properties against moisture, gases, and light, ensuring the integrity and shelf life of the aerosol products. Additionally, tinplate's high strength and durability make it ideal for withstanding the pressure and handling requirements of aerosol packaging.

- Q: How is tinplate coated for chemical storage containers?

- Tinplate is typically coated for chemical storage containers using a process called electrolytic tin plating, where a layer of tin is electrochemically deposited onto the surface of the steel substrate. This tin coating helps to protect the container from corrosion and chemical reactions, ensuring safe storage and transportation of chemicals.

- Q: Can tinplate be painted?

- Yes, tinplate can be painted.

Send your message to us

PET Laminiated TFS for 0.19mm Thickness Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords