Personalised Packaging Tape UK - BP-60 BOPP Adhesive Tape BOPP Film Water Based Acrylic

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product description

| Material: | BOPP | Use: | Carton Sealing | Adhesive Side: | Single Sided |

| Adhesive: | Acrylic | Adhesive Type: | Pressure Sensitive, Water Activated | Feature: | Waterproof |

| Design Printing: | Offer Printing | Place of Origin: | Beijing, China (Mainland) | MOQ | 1800 rolls |

2.Packaging & Delivery

Packaging Details:

1) individually wrapped,

2)6rolls/ Tower shrink/ Flat_pack,

3)about 36~100rolls/cartonDelivery Detail:

within 15 days after comfirming the deposit and packaging detail

3.Product show

4.Company information

CNBM International Corporation (CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.

We specilized in Duct tape, Masking tape, Double sided tissue tape, PET tape, Foam tape, PVC tape, Warning tape, Fiberglass tape…Now we have exported our products to over 30 countries and regions like Europe ,South / North America ,Southeast Asia etc and gained customer's respect and continued businesses. Based on our good quality , reasonable price, good after-sale service, we enjoyed good reputation in the international market.

Warmly welcome your any inquiries or request ! You will be impressed by our superior quality, quick delivery date and attractive price. Contact us now!

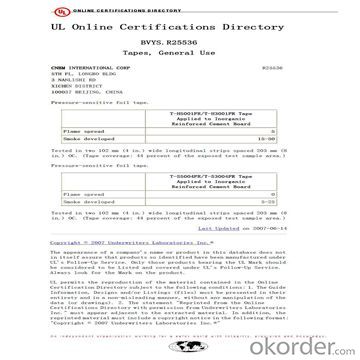

5.Our certification

6.Our services

1.OEM Service

Your own design is appreciated; we can make the approval sample according to your golden sample.

2. QC Service

a) Before the order to be confirmed, we should check the material & color of fabric by sample which should be strictly.

b) We will be tracing the different phase of production from the beginning.

c) Every bad quality will be checked & cleaned before packing.

d) Before delivery clients could send one QC or point the third party to check the quality.

e) We will try our best to help clients when problem occurred.

3. After-sale Service

a) EXW, FOB, C&F are also available for us.

b) If the products need certificate, we can also provide.

7.FAQ:

Q1: Are you manufacturer or trading company?

A: We are professional Manufacturer.

Q2: Can I use our own designing?

A: Yes, size, printing, color, paper core, logo, carton box can be customized.

Q3: May I have samples?

A: Yes, Free samples available and freight collect by DHL, FEDE

- Q: What are the considerations for using packaging tape on corrugated cardboard boxes?

- When using packaging tape on corrugated cardboard boxes, it is important to consider the strength and durability of the tape, as well as its adhesive properties. The tape should be strong enough to securely seal the box and withstand any potential stress or weight during handling and transportation. Additionally, the tape's adhesive should be able to adhere well to the corrugated surface and provide a tight seal, preventing any contents from shifting or falling out. It is also advisable to choose a tape that is easy to apply and tear, ensuring efficient packaging processes.

- Q: What are the considerations for using packaging tape on textured surfaces?

- When using packaging tape on textured surfaces, there are a few considerations to keep in mind. Firstly, the texture of the surface can affect the adhesion of the tape. Textured surfaces typically have uneven or rough areas, which may make it difficult for the tape to adhere securely. It is important to choose a packaging tape that is specifically designed for textured surfaces. These tapes usually have a stronger adhesive that can better stick to uneven surfaces, ensuring that the tape will stay in place. Another consideration is the durability of the tape. Textured surfaces can be more abrasive than smooth surfaces, which can cause the tape to wear out more quickly. It is important to select a packaging tape that is made from a durable material, such as reinforced or heavy-duty tape. These types of tape are designed to withstand more wear and tear, providing a longer-lasting bond on textured surfaces. Additionally, the texture of the surface can also affect the appearance of the tape. Since textured surfaces are not smooth, the tape may not lay flat and can create air pockets or wrinkles. This can make the package look untidy or unprofessional. To improve the appearance, it may be necessary to use extra tape or apply it in a way that smooths out any unevenness. Lastly, it is important to consider the removal of the tape from textured surfaces. Textured surfaces can make it more difficult to remove the tape cleanly without leaving behind any residue. To prevent damage to the surface or any sticky residue, it is recommended to test the tape on a small, inconspicuous area before fully applying it. If the tape does leave residue, there are adhesive removers available that can help safely remove any remaining residue. In summary, when using packaging tape on textured surfaces, it is important to choose a tape specifically designed for uneven surfaces, select a durable tape that can withstand the texture, consider the appearance of the tape on the textured surface, and be cautious of any potential residue left behind when removing the tape.

- Q: Can packaging tape be used for sealing chemical or hazardous material containers?

- Packaging tape is not recommended for sealing chemical or hazardous material containers. This is because packaging tape typically does not have the necessary properties to effectively contain and prevent leakage of these substances. Chemical or hazardous materials often require specialized containers and sealing methods to ensure safety and compliance with regulations. These containers are designed to withstand the corrosive or reactive nature of the substances they hold, and their seals are engineered to provide a secure and leak-proof closure. Using packaging tape to seal chemical or hazardous material containers can pose risks such as leakage, contamination, and exposure to harmful substances. It may not provide a reliable barrier against leaks or spills, which could result in accidents, injuries, or environmental damage. To properly seal chemical or hazardous material containers, it is recommended to use specific sealing materials that are designed for these purposes. This may include specialized caps, gaskets, or seals that are compatible with the particular substance being contained. Additionally, it is crucial to follow the guidelines and regulations provided by relevant authorities for the safe handling, storage, and transportation of these materials.

- Q: Can packaging tape be used for sealing pet supplies or accessories?

- Yes, packaging tape can be used for sealing pet supplies or accessories. It provides a strong and secure seal, ensuring that the items are protected and contained during transportation or storage.

- Q: Does packaging tape leave residue?

- Indeed, surfaces can be affected by residue when packaging tape is used. This occurrence arises from the fact that the majority of packaging tapes possess adhesive properties, meant to firmly adhere to surfaces. Consequently, when the tape is detached, it has the potential to leave a sticky residue behind which may prove arduous to eliminate. Moreover, this residue is prone to accumulating dust and dirt, thereby intensifying the difficulty of the cleaning process. Nonetheless, there are certain packaging tapes available that are explicitly engineered to minimize or entirely eliminate residue upon removal. To guarantee the absence of any unwanted residue, it is always prudent to conduct a preliminary test on a small area of delicate or valuable surfaces before employing packaging tape.

- Q: I want to be involved in the tape industry, is the parent type their split, but do not know the parent roll cut in segmentation machine is good, or even after the parent roll processing, and also is the problem of the equipment, how much money, thank you

- Also known as sealing tape, packing tape, which is based on BOPP biaxially oriented polypropylene film as substrate, after heating evenly pressure-sensitive emulsion, the formation of 8 mu m----28 Mu ranging from m layer, light industry enterprises, companies and individuals are indispensable in life activities,

- Q: Can packaging tape be used for sealing construction or building materials?

- Yes, packaging tape can be used for sealing construction or building materials, but it may not provide the same level of durability and longevity as specialized tapes designed for such purposes.

- Q: Is packaging tape resistant to chemicals or solvents?

- Generally, chemicals and solvents do not pose a threat to packaging tape. Packaging tapes are typically composed of materials like polypropylene or polyvinyl chloride (PVC), which possess excellent chemical resistance. These materials are specifically engineered to endure exposure to a broad array of chemicals and solvents commonly found in industrial or commercial settings. Nevertheless, it is crucial to acknowledge that the resistance of packaging tape may differ depending on factors such as the brand, type, and quality of the tape. Consequently, it is advisable to review the product specifications or seek guidance from the manufacturer to obtain detailed information regarding the chemical resistance of a particular tape.

- Q: What are the considerations for using packaging tape on plastic or polyethylene bags?

- There are several factors to consider when using packaging tape on plastic or polyethylene bags. To begin with, it is crucial to choose the appropriate type of packaging tape for these surfaces. Certain tapes may not adhere well to plastic or polyethylene, resulting in poor adhesion and easy peeling. It is advisable to opt for tapes specifically designed for these materials, as they are typically formulated with adhesive that adheres properly. Another factor to take into account is the tape's strength and durability. Plastic bags are often lightweight and flexible, so it is important to select a tape that can provide sufficient strength to secure the bag's contents. Look for tapes with a strong adhesive backing that are resistant to tearing or stretching. Consideration should also be given to temperature and environmental conditions. Extreme temperatures can impact the tape's adhesive properties, leading to decreased adhesion or brittleness. If the bags will be exposed to high or low temperatures, it is recommended to choose a tape specifically designed for those conditions. Furthermore, it is essential to ensure that the tape does not cause any damage to the plastic or polyethylene bags. Some tapes may have strong adhesives that leave residue or cause harm when removed. Look for tapes labeled as having low residue, easy removal, or being safe for use on these surfaces. Lastly, aesthetics and presentation should be considered. Packaging tape is available in various colors and designs, allowing you to choose a tape that complements the bag's appearance or branding. It is important to make sure that the tape does not obstruct any important information or barcodes on the bag. In conclusion, when using packaging tape on plastic or polyethylene bags, it is important to consider selecting the right tape, ensuring strength and durability, taking into account temperature and environmental conditions, preventing damage to the bags, and considering aesthetics and presentation.

- Q: General adhesive tape is a taste, the size of the taste depends on the formula of glue, low molecular weight content, taste will be larger, once adhesive tape, it has a very small taste tape, we have been using.

- The bubble is on the tape slitting machine when cutting the air into the tape to improve only by changing the type or sub machine will have a bubble for 1 months or longer, the bubbles will automatically eliminate, the premise is to increase the cutting of the tape tension, if loose, put a few day and bubble;

Send your message to us

Personalised Packaging Tape UK - BP-60 BOPP Adhesive Tape BOPP Film Water Based Acrylic

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords