Casing Pipe for water well

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

API 5CT M65 casing pipe

Our company produces M65 casing pipe strictly according to the API 5 CT standards.Dalipal Company is one of the most famous enterprises of china professionally producing pipeline and oil casing.We can supply API 5CT series of pipeline and oil casing with all kinds of specifications and materials.We have first-class production equipment and technology.

Main Specification

Grade | API 5CT M65 Casing Pipe for water well |

External thickness | “4 1/2- 20”inch, (114.30- 508.00 mm) |

Wall thickness | 5.21-16.13 mm |

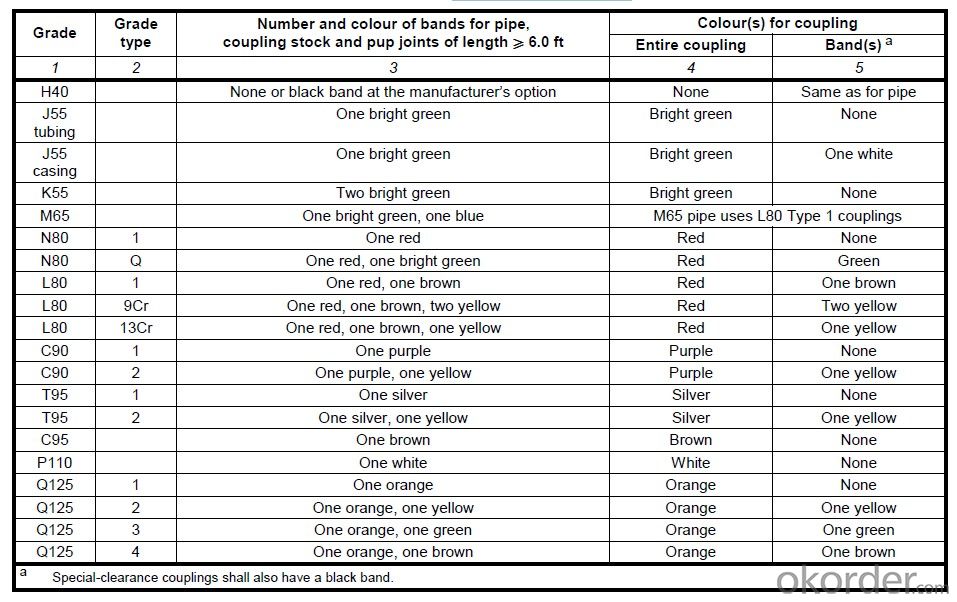

Grade M65 for API threads | There are no Grade M65 couplings. Grade L80 Type 1 couplings shall be used on Grade M65 pipe. |

Function | used for protecting pipeline |

Length:

R1-(6.10m~7.32m),R2-(7.62/8.53)~10.36m,R3-(10.36/10.97~14.63m)

Certificate:

API 5CT,Russian Certificate,ISO,CCS

Packing:

Coating and steel thread protector

Oil Casing Pipe Grade colour codes

Usage:

Casing pipes are used for oil , gas and water wells. Steel casing pipes and tubing are applied to furnishing and installing cased tunnels, where they indicate to pass other utilities or obstructions without open excavation. Steel casing pipes and tube have smooth wall and a minimum yield strength of 35,000 psi. Corrosion-proofing water-based paint is applied on the outside pipe surface to protect against atmospheric corrosion during transportation and storage. The pipes can be delivered with metal or composite caps at both ends for thread protection.Casing pipes are manufactured out of steel are smelted in the electric furnace, treated with synthetic slags and cast by continuous casters. The applied steel making process ensures the achievement of chemically pure steel with reference to sulphur and phosphor contents providing high tensile, ductility and corrosion resistance properties of pipes to be operated at low temperatures in various corrosion media. Pipes are heat-treated in a computerized walking beam furnace. Steel grades and heat treatment regimes applied allow high-strength pipe to be obtained.

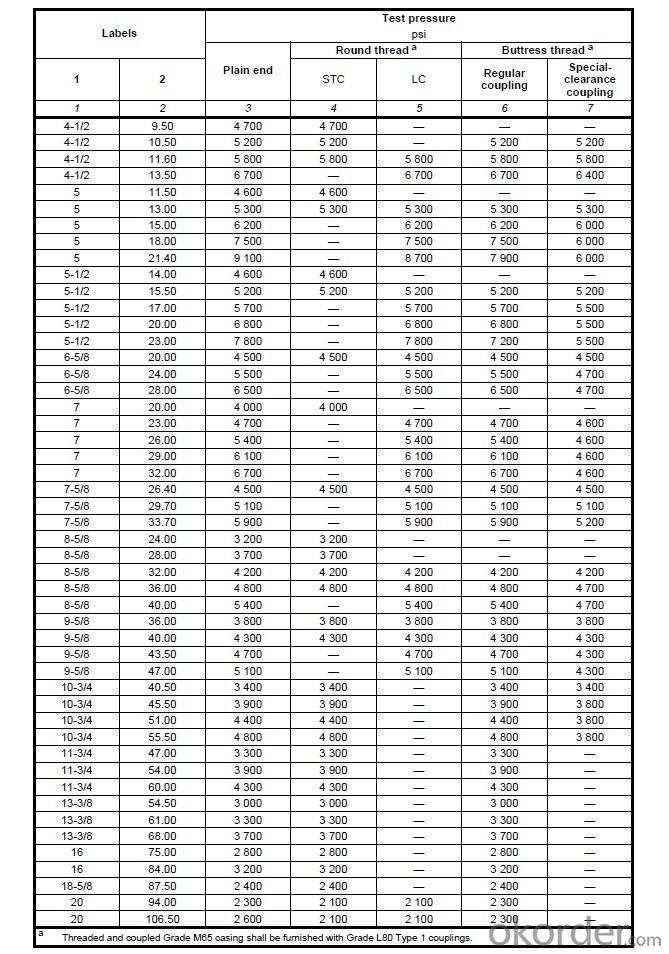

API Specification 5CT / ISO 11960

Hydrostatic test pressure for Grade M65 casing

We have the ability to detect the whole process. We can fully guarantee the high quality of the products.

- Q: What are the common methods of joining steel pipes?

- The common methods of joining steel pipes include welding, threading, and using mechanical couplings. Welding involves fusing the pipes together using heat, while threading involves screwing the pipes together using threads on the ends. Mechanical couplings are devices that connect the pipes together using compression or other means.

- Q: How long do steel pipes typically last?

- Steel pipes typically last for several decades, with an average lifespan ranging from 50 to 100 years depending on various factors such as usage, maintenance, and environmental conditions.

- Q: How are steel pipes connected together?

- Steel pipes are typically connected together using various methods such as welding, threading, or using mechanical fittings, depending on the specific application and requirements.

- Q: How are steel pipes used in the transportation industry?

- Steel pipes are used in the transportation industry for various purposes, including the construction of pipelines for transporting oil, gas, and other fluids. They are also used in the manufacturing of vehicles, such as cars, trucks, and trains, where they are commonly used for exhaust systems and structural components. Additionally, steel pipes are utilized in the construction of bridges, tunnels, and other infrastructure projects that support transportation networks.

- Q: How do you determine the wall thickness of a steel pipe?

- There are several methods available for determining the wall thickness of a steel pipe. The most commonly used and precise approach involves utilizing a caliper or micrometer to measure it. Initially, ensure that the pipe is thoroughly cleaned and devoid of any debris or rust. Subsequently, gently position the caliper or micrometer around the circumference of the pipe, making certain that it is perpendicular to the surface. Proceed to cautiously close the jaws of the measuring tool until they snugly fit against the pipe, taking care not to excessively tighten them and distort the shape. Once the jaws are closed, observe and take note of the measurement displayed on the tool. This reading corresponds to the distance between the inner and outer diameter of the pipe, which is equivalent to the wall thickness. Alternatively, if a caliper or micrometer is unavailable, a pipe wall thickness gauge can be utilized. These gauges are equipped with a series of pins or rollers that can be inserted into the pipe, providing an accurate measurement. Simply insert the pins into the pipe, ensuring proper alignment with the wall, and refer to the reading displayed on the gauge. It is crucial to note that when measuring the wall thickness of a steel pipe, multiple readings should be taken at various points along the pipe to account for any variations. This will yield a more precise average measurement.

- Q: Can steel pipes be used for underground pressure pipelines?

- Yes, steel pipes can be used for underground pressure pipelines. Steel pipes are known for their strength, durability, and resistance to corrosion, making them suitable for underground applications where pressure is present. Additionally, steel pipes can withstand high temperatures and external forces, making them an ideal choice for underground pressure pipelines.

- Q: How are steel pipes protected against external mechanical damage?

- Steel pipes are often protected against external mechanical damage through a variety of methods such as applying corrosion-resistant coatings, using protective sleeves or wraps, and implementing casing or encasement systems. These measures help to safeguard the pipes from potential physical harm caused by external factors like impact, abrasion, or heavy loads, thus ensuring their integrity and longevity.

- Q: How are steel pipes classified based on pressure ratings?

- Steel pipes are classified based on pressure ratings by assigning them different schedules, ranging from Schedule 10 to Schedule 160. Each schedule represents a different maximum pressure that the pipe can withstand, with higher schedules indicating higher pressure ratings.

- Q: Are steel pipes resistant to fire?

- Yes, steel pipes are highly resistant to fire due to their high melting point and ability to withstand intense heat and flames.

- Q: What are the different types of steel pipe nipples?

- There are various types of steel pipe nipples, including standard, close, barrel, hexagonal, and welding nipple. Each type serves a specific purpose and has unique characteristics.

Send your message to us

Casing Pipe for water well

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords