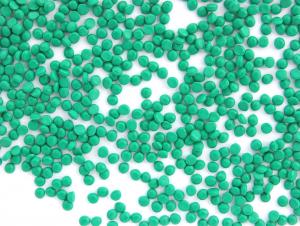

PE Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PE Compound

I. Type andapplication

Type | Product | Application |

NDH | Black LDPE jacket compound for resistance to environmental stress crack | Jacket of telephone cable, RF cable and optical cable |

LDH | Black LLDPE jacket compound | |

MH | Black MDPE jacket compound | |

GH | Black HDPE jacket compound | Jacket of optical cable. High strength and abrasion resistant jacket |

NLDJ | Black weatherability LLDPE insulating compound | |

NGJ | Black weatherability HDPE insulating compound | Insulation of aerial cable |

ZPE | Flame retardant PE compound | Flame-retardant insulating or jacket of 70~90℃wires and cables |

RDH | Flexible PE jacket compound | Flexible PE jacket of 70℃wires and cables |

II. PE compound, based on PE resin, isproduced and pelletized with the double corrugated screw, in which variousadditives are added. The compound is according to GB 15065-94 and IEC 60502. The compound has outstandingperformances of processing, physical, mechanical and electrical properties.

III. Processing: It is recommended thatcompound should be processed with extruder having a minimum L/D ratio of 25.Compound (not including ZPE) should be thoroughly dried before use, and the maximum drying temperature should notexceed 100℃.

Thefollowing temperature(℃) profile of extruder is recommended:

Type | Zone 1 | Zone 2 | Zone 3 | Zone 4 | head | die |

NDH | 180 | 190 | 200 | 210 | 220 | 230 |

LDH | 170 | 180 | 190 | 200 | 210 | 220 |

MH | 180 | 210 | 220 | 230 | 245 | 240 |

GH、NGJ | 190 | 215 | 230 | 245 | 245 | 240 |

NLDJ | 160 | 180 | 195 | 200 | 200 | 210 |

ZPE | 140 | 150 | 160 | 170 | 170 | 165 |

RDH | 140 | 160 | 175 | 180 | 190 | 190 |

Note: The processing parameters are forreference only, optimal conditions may vary according to the equipment used.The cooling water tank should be used sectionally cooling with warm-waterechelon in order to reduce internal stress.

ⅳ. Properties

Unit | NDH | GH | LDH | MH | RDH | ||||||

Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

Volume Resistivity at 20℃ | ≥Ω﹒m | 1.0×1014 | 1.1×1015 | 1.0×1014 | 8.0×1014 | 1.0×1014 | 8×1014 | 1.0×1014 | 3.6×1014 | 1.0×1013 | 3.0×1013 |

Dielectric Strength | ≥MV/m | 25 | 37 | 25 | 35 | 25 | 32 | 25 | 35 | 25 | 28 |

Dielectric Constant | ≤ | 2.80 | 2.36 | 2.75 | 2.40 | 2.80 | 2.35 | 2.75 | 2.4 | - | - |

Dielectric Loss, Angular Tangent | ≤ | - | - | 0.005 | 0.0006 | - | - | 0.005 | 0.001 | - | - |

Melt Flowing Index | ≤g/10min | 2.0 | 0.9 | 0.5 | 0.3 | 2.0 | 1.1 | 1.0 | 0.5 | 2.0 | 1.9 |

Density | g/cm3 | 0.920- 0.949 | 0.936 | 0.950- 0.978 | 0.953 | 0.920- 0.945 | 0.938 | 0.940- 0.955 | 0.945 | - | - |

Tensile Strength | ≥MPa | 13.0 | 19.0 | 20.0 | 23.0 | ≥14.0 | 18.0 | ≥17.0 | 23.0 | 13.0 | 17.0 |

Yield Strength | ≥MPa | - | - | 16.0 | 20.0 | - | - | - | - | - | - |

Elongation at Break | ≥% | 500 | 790 | 650 | 850 | 600 | 700 | 600 | 800 | 500 | 590 |

Low Temp. Elongation at Break | ≥% | - | - | 175 | 210 | - | - | - | - | - | - |

Impact Brittleness in low temp. | ≤℃ | -76 | Pass | -76 | Pass | -76 | Pass | -76 | Pass | -76 | Pass |

Dispersity of Carbon Black | ≥ Scatter | 6 | 7 | 6 | 7 | 6 | 7 | 6 | 7 | 6 | 7 |

Carbon Black Content | % | 2.60±0.25 | 2.6 | 2.60±0.25 | 2.6 | 2.60±0.25 | 2.6 | 2.60±0.25 | 2.6 | 2.60±0.25 | 2.6 |

Resistance to Environmental Stress Crack F0 | ≥h | 96 | Pass | 500 | Pass | 500 | Pass | 200 | Pass | 96 | Pass |

200℃ Oxidative Induced Time | ≥min | 30 | Pass | - | - | 30 | Pass | 30 | Pass | 30 | Pass |

Note: 1、The sample made method is thermoplastic pressing which is accord toGB9352 standard.

Item | Unit | NLDJ | NGJ | ZPE | |||

Standard | Typical | Standard | Typical | Standard | Typical | ||

Volume Resistivity at 20℃ | Ω﹒m | ≥1.0×1014 | 8×1014 | ≥1.0×1014 | 8×1014 | ≥1.0×1011 | 5.0×1012 |

Dielectric Strength | MV/m | ≥25 | 35 | ≥35 | 40 | ≥20 | 25 |

Dielectric Constant | ≤ | - | - | ≤2.45 | 2.35 | - | - |

Dielectric Loss, Angular Tangent | ≤ | - | - | ≤0.001 | 0.0008 | - | - |

Melt Flowing Index | g/10min | ≤1.0 | 0.6 | ≤0.4 | 0.2 | 2.0 | 1.36 |

Density | g/cm3 | 0.920- 0.945 | 0.938 | 0.955- 0.978 | 0.958 | - |

|

Tensile Strength | MPa | ≥14.0 | 20.0 | ≥20.0 | 28.0 | ≥10.0 | 15.0 |

Yield Strength | MPa | - | - | ≥16.0 | 20.0 | - | - |

Elongation at Break | % | ≥600 | 750 | ≥650 | 830 | ≥250 | 650 |

LowTemp.Elongation at Break | % | - | - | ≥175 | 240 | - | - |

Impact Brittleness in low temp. | ℃ | ≤-76 | Pass | ≤-76 | Pass | -40 | Pass |

Dispersity of Carbon Black | Scatter | ≥6 | 7 | ≥6 | 7 | - | - |

Resistance to Heat Stress Crack | h | - | - | ≥96 | Pass | - | - |

Resistance to Environmental Stress Crack F0 | h | ≥500 | Pass | ≥500 | Pass | ≥96 | Pass |

Vicat Softening Temp. | ℃ | - | - | ≥110 | 127 | - | - |

Air oven aging |

| 100℃×10d | 100℃×10d | 100℃7d | |||

Tensile Strength after aging | MPa | ≥13.0 | 19.0 | ≥20.0 | 26.0 | ≥10.0 | 14.6 |

Elongation atBreak after aging | % | ≥500 | 700 | ≥650 | 760 | ≥250 | 670 |

(0-1008)h Artificialweatheringaging time |

|

|

|

|

|

|

|

Variation on Tensile Strength | % | ±25 | 14.5 | ±25 | 15.5 | - | - |

VariationonElongationat Break | % | ±25 | 17.2 | ±25 | 18.3 | - | - |

(504-1008)h Aging time |

|

|

|

|

|

|

|

Variation on Tensile Strength | % | ±15 | 12.5 | ±15 | 10.2 | - | - |

VariationonElongation atBreak | % | ±15 | 10.5 | ±15 | 9.5 | - | - |

Oxygen Index |

| - | - | - | - | ≥26 | 26.4 |

- Q: What can plastic particles do?

- 1, daily life, can be used to make all kinds of plastic bags, barrels, pots, toys, furniture, stationery and other living utensils and all kinds of plastic products.2, clothing industry: can be used to make clothing, neckties, buttons, zippers and so on.3. Building materials: can be used to make all kinds of building components, building tools, plastic doors and windows, mortar barrels, etc..

- Q: Are there any regulations or restrictions on using olive nets?

- Yes, there are regulations and restrictions on using olive nets. These regulations vary by country and region, but generally, they aim to protect the olive trees and ensure sustainable harvesting practices. Some common restrictions include limitations on the size and type of nets used, specific periods for net installation and removal, and guidelines for proper installation techniques to avoid tree damage. It is important for olive farmers to familiarize themselves with the local regulations and comply with them to maintain the health and productivity of their olive groves.

- Q: What is the best plastic welding method?

- It must be welding with ultrasonic wave! Because he doesn't need other additives, and the efficiency and welding effects are not artificial. Unless you're a big plastic product.

- Q: What are the processing methods of black masterbatch and what is more prominent than other plastic raw materials?

- In the dyeing of plastic products, black masterbatch only 0.6%-0.8%, it will be extremely black, and no more will not be more dark. According to the experimental data show that the product in Xinjiang area for outdoor use, such as the need to rely on black masterbatch anti aging, as long as the use of high-quality black masterbatch (rather than return material as carrier, oil wetting, dispersion of calcium carbonate and so on it), content of carbon black in the products reached 2-2.5%, namely: every 100 kilograms of raw materials, there is a 5-6 (the weight of 40%) containing carbon black masterbatch, the role played by far more than any anti aging products, product life can reach more than 10 years. That's why drip irrigation products, water delivery products, communications cable products are all black.

- Q: What kind of plastic bottles can be used again and again?

- Plastic bottle and digital security unrelated to market rumors, some plastic bottles are safe, can be used repeatedly, and see a plastic bottle repeatedly with safe, through the identification of the bottom of the bottle. Online friends said, at the bottom of a lot of beverage bottles, bottles of mineral water has a triangular sign with an arrow that has a digital triangle, if the number of "05" or more can be recycled, and digital more safe. "The general mineral water bottle at the bottom of mark 01; general tea cup bottom plastic label 05; cream bottle at the bottom of mark of 02; the bottom of the bottle marked 02 yogurt......" This post sends out, that causes the netizen to discuss hotly, some people approve, but some people doubt its authenticity

- Q: Are olive nets suitable for olive tree seedling nurseries?

- Yes, olive nets can be suitable for olive tree seedling nurseries. Olive nets provide protection from excessive sunlight and wind, ensuring optimal growing conditions for young olive tree seedlings. They also help prevent damage caused by birds or other animals, ensuring the successful growth and development of the seedlings.

- Q: How do olive nets prevent olives from being damaged by animals digging around the tree?

- Olive nets prevent olives from being damaged by animals digging around the tree by creating a physical barrier that prevents animals from reaching the olives. The nets are typically placed around the base of the tree, covering the ground, and secured tightly to prevent any gaps. This effectively blocks access for animals like rodents, rabbits, or other creatures that may attempt to dig around the tree to reach the olives.

- Q: Are olive nets suitable for organic farming certifications?

- Yes, olive nets are suitable for organic farming certifications. These nets are commonly used in organic farming to protect olive trees from pests and birds without the use of chemicals. They provide a natural and non-toxic solution for maintaining the organic integrity of the crop, making them a suitable option for organic farming certifications.

- Q: What is an olive net?

- An olive net is a type of netting used in olive orchards to catch the olives as they fall from the trees during harvesting.

- Q: What materials are olive nets typically made of?

- Olive nets are typically made of durable and lightweight materials such as nylon or polypropylene.

Send your message to us

PE Compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords