Office Furniture Commerical Desk/Table Solid Wood CMAX-BG204

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type: | Office Furniture | Specific Use: | Office desk | Style: | Commerical Desk |

Material: | MDF/MFC,Melamine | Folded: | No | Color | All color are available |

Volume: | 0.19 m3 | customization: | Yes | Model | CMAX-BG204 |

MOQ | 20 sets | Warranty | 2 years | General Use: | Commercial Furniture,office desk,office furniture,for executives/directors/presidents |

We specialized in office desk and office seating .

Our factory has been engaged in office furnitur e for more than 10 years.

Our factory is wellknown in the high quality and competitive price of our products.

Therefore, we completed in specifications and win warm praise from customers.

In addition, the design of our products is deft, modern and beautiful.

There are many types and colors for your selection.

Our goods are easy and simple to handle and durable in use.

Whether you need 1 office chair or big modular furniture, we offer the service, experience and attention you deserve -no matter how big or small the job is.

Your satisfaction is our goal, that's why we only supply furniture from top brands!

From workstations to cubicles, we have them all.

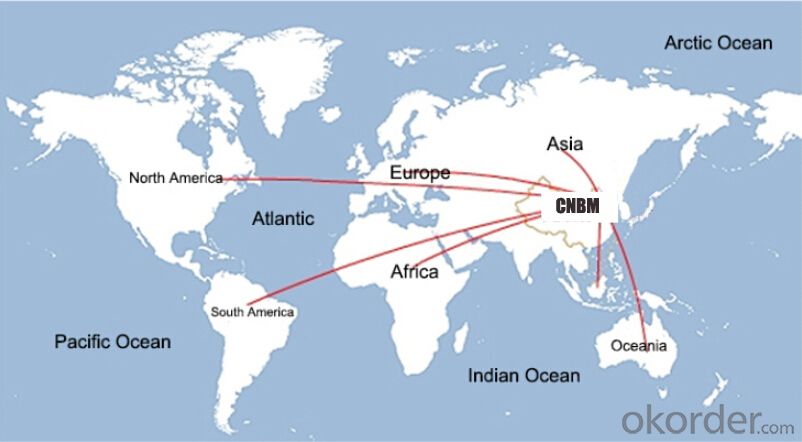

CNBM have a team of friendly and knowledgeable office Furniture and industrial furniture specialists with a specialists division who cater to our clientele who are looking for complete Office fitouts. At ROF we supply you more then just the chair or desks for your new working space, we create engaging and fresh office fitouts using our extensive range of Australia's best designs and qualities of office Furniture and industrial furniture.

Welcome any questions!

1. Features

1) Material: PU, PVC and fabric available

2) Height is adjustable

3) Rotary max. to 360

4) Slide freely with wheels

5) Designs and Patterns available upon requests

6) Different colors are available

7) Elegant design, excellent workmanship

8) Height of the seat and backrest are suitable

9) The pad thickness of the seat and backrest are suitable

2. Quality Control

1) Every product quality will be checked & cleaned before packing

2) We will try our best to help clients when problems occurred

3) Every step of production is carefully inspected by our professional QC clerk to ensure the quality of our products

CMAX-BG642

2800*1225*1060

CMAX-BG141

2825*675*1125

CMAX-BG204

1450*2825*1125

CMAX-BG821

1500*2825*1050

FAQ

Why choose us?

1, Advantage: Directly manufacturing factory with competitive price and quality control, we check all material when we start to bulk productions.

2, Professional advice to help you purchase the products you wanted/

3, Professional export service team servers in the deal.

4, Customization service is available, OEM business is appreciated.

5, We will inspect and test all products material carefully to ensure no damage and lost.

6, The success of our cooperation can be guaranteed for our company is a credible and honest partner.

How about the quality ?

1.Our normal material of MDF and MFC is with E1 standard. All oil paint we use is enviropaints. All kinds of Certification is available.Besides all the material could be customized.

How about the payment term?

1.Usually 30%T/T in Advace, the balance before shippment. L/C at sight could also be accept.

Other payment term could be discussed with specific orders.

Can you give warranty of your products?

Yes, we can supply 2 years warranty for our normal items. For the overseas orders, please provided emails with details including pictures, we will send replacements (Such as castors, screws, plastic pad of base) at our cost to repair the chairs in some coming orders.

- Q: Plywood office furniture?

- MDF is divided into medium density, high density and so on. MDF furniture is generally available - affordable and environmentally friendly.

- Q: What kind of glue does plywood use now?

- According to the environmental protection grade, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and unqualified glue which can not reach E2 grade). E0 class is the highest environmental protection level. Plywood made of grade E1 glue can be used directly indoors.High quality urea formaldehyde adhesive / melamine adhesive / phenolic resin can be up to E0 and E1 grades, which can be used directly in the room.

- Q: What is LVL plywood?

- Compared with solid wood lumber, LVL has many advantages that LVL does not have:(1) LVL can log scar section, cracks and other defects scattered, staggered, thus greatly reduce the influence of strength, its quality and stability, strength uniform, material variability is small, is the most ideal alternative log structure material;(2) the size can be adjusted at will, not affected by the shape and defect of the log(3) LVL processing, like wood, can be sawing, cutting, gouging, gouging, nail, and so on;(4) LVL has the properties of pest control, corrosion protection, fire prevention and waterproof. It mainly adopts the corresponding pretreatment in the process of making or takes the special adhesive;(5) LVL has excellent seismic performance and shock absorption performance as well as resistance to fatigue damage caused by cyclic stress;(6) this product is green and pollution-free.

- Q: Building engineering wood plywood can turn over several times?

- Architectural templates are hierarchical,Good template, in theory can use about 10 times, of course, the actual use can not reach, generally can use about 6 times

- Q: How can the knife switch, glass plate and rubber sheet be distinguished?

- The majority of users choose rubber board, it is not required for the environment, and the insulation performance is more stable. And generally consider cost-effective users choose glass plate more.

- Q: In the present construction, bamboo plywood or plastic board?

- The edge of bamboo plywood is easily damaged after collision, and the bamboo plywood is suitable for drying and less collision;

- Q: What's the difference between plywood and plywood?

- Plywood is one of the commonly used furniture materials. It is a kind of artificial board. Plywood, also known as plywood, the line is commonly known as fine core board. Made of three or more layers of a single sheet of a millimeter thick veneer or glued. Handmade furniture is the most commonly used materials.

- Q: Do you make furniture, carpentry or plywood? Which one is more expensive?

- Although the wood board glue is not much, but you don't forget to brush glue stick panel, the panel also good paste paint, glue and paint are contaminated, but think of with plywood, blockboard evaporate faster, this is the wood board than plywood good, not good where is the long construction time, carpentry and painting work craft directly affect the final effect. There is a wood board easily model.

- Q: Desulfurization absorption tower anticorrosive lining glue, specifications have stipulated, rubber board need sampling?

- In addition to the quality inspection of the appearance of the rubber plate, rubber plate (after curing) to physicochemical properties were tested, the test contents are: tensile strength, tensile strength, stretching rate, volume weight, hardness and bonding strength of plywood and the matrix, the above indexes must be rubber lining construction quality can be guaranteed, the above index must be qualified to ensure the final quality of the rubber lining construction. The adhesive properties also play an important role in the final quality of the anticorrosive lining. The rational properties of the general rubber sheet and mortar are tested in the manufacturer. The inspection of rubber plate and glue for rubber lining equipment is an essential step, and must pay attention to it!

- Q: What is bamboo plywood?

- Bamboo is widely used, the level of template, suitable for building construction in shear wall, vertical wall, dam, bridge, viaduct, tunnel and subway pile beam template, also widely used in a variety of containers, packaging boxes, car and train floor, home floor, indoor ceiling, doors, furniture etc..

Send your message to us

Office Furniture Commerical Desk/Table Solid Wood CMAX-BG204

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords