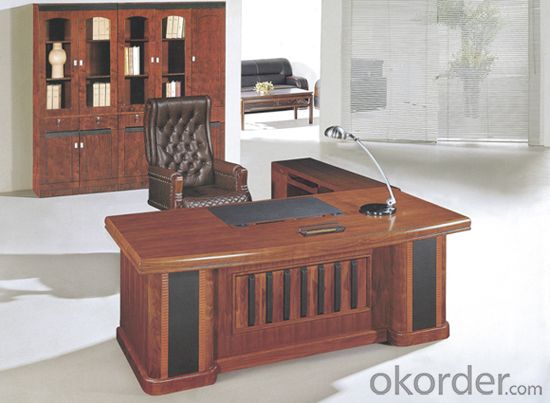

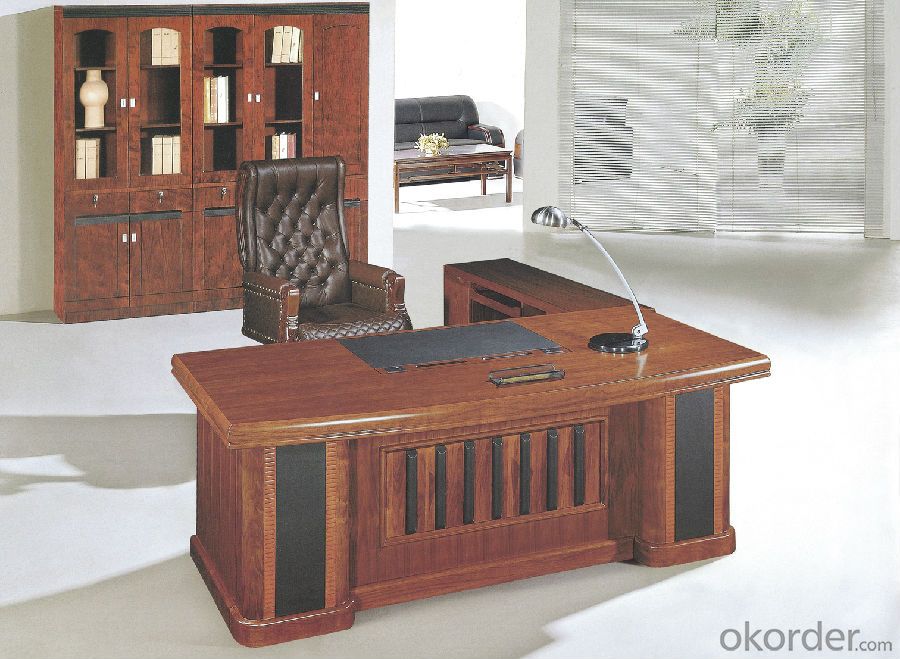

Office Furniture Commerical Desk/Table Solid Wood CMAX-BG029

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Office Furniture – Solid Wood Commercial Desk CMAX-BG029

Description of Office Furniture Commerical Desk/Table Solid Wood CMAX-BG029:

Type: | Office Furniture | Use: | Office Desk | Style: | Commercial Desk |

Material: | MDF/MFC, Melamine | Folding: | No | Color: | All Colors Available |

Volume: | 0.18 m³ | Customization: | Yes | Model: | CMAX-BG029 |

MOQ: | 20 Sets | Warranty: | 2 years | Use: | Commercial Furniture, office desk, office furniture |

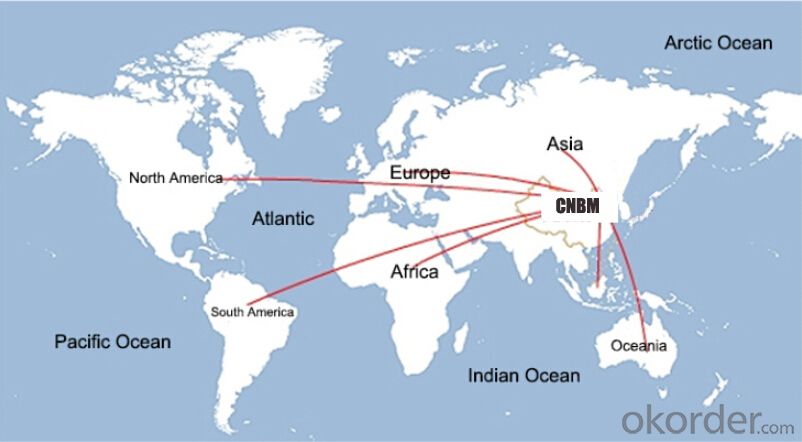

We specialized in office desks and office seating. Our factory has been engaged in office furniture for more than 10 years and our factory is well-known for the high quality and competitive prices of our products. Our factory is well-known for the high quality and competitive prices of our products. We have won the praise of customers.

There are many types and colors to choose from. Our goods are easy and simple to handle and durable in use. Whether you need an office chair or modular furniture, we offer the service, experience and attention you deserve – no matter how big or small the job. Your satisfaction is our goal, that's why we only supply furniture from top brands! From workstations to cubicles, we have them all.

CNBM have a team of friendly and knowledgeable office Furniture and industrial furniture specialists who cater to our clientele looking for complete office fit outs.

We welcome any questions!

CMAX-BG029

1. Features of Office Furniture Commerical Desk/Table Solid Wood CMAX-BG029

1) Material: PU, PVC and fabric available

2) Height is adjustable

3) Rotation to 360°

4) Slide freely with wheels

5) Designs and patterns available upon request

6) Different colors are available

7) Elegant design, excellent workmanship

8) Height of seat and backrest adjustable

9) Seat pad thickness and backrest adequate

2. Quality Control of Office Furniture Commerical Desk/Table Solid Wood CMAX-BG029

1) Each product is checked & cleaned before packaging

2) We do our best to resolve problems when they occur

3) Every step of production is carefully inspected by our professional QC team to ensure the quality of our products

CMAX-BG029

1600*800*760

1800*900*760

2000*1000*760

CMAX-BG032

1600*800*760

1800*950*760

2000*1000*760

CMAX-BG059

1600*800*760

1800*900*760

2000*1000*760

CMAX-BG062

1600*800*760

1800*900*760

2000*1000*760

CMAX-BG057

1800*1900*760

2000*2000*760

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What about payment term?

A4: We accept 30%T/T in advance, with the balance before shipment. L/C at sight is also acceptable. Other payment term can be discussed with specific orders.

- Q: How do electrophoresis plates do?

- 10 L DNA and 2 l sample volume bromophenol blue indicator sample buffer. The mixed sample buffer can not only improve the density of the sample, the sample is evenly sink to the sample hole, also can make samples with color, easy to sample and estimate and judge the position of electrophoresis electrophoresis time;8 use micro pipette to add sample carefully to sample hole, record sample order;9, cover the electrophoresis tank, turn on the power switch, the maximum voltage is not more than 5V/cm (100 ~ 150V constant voltage electrophoresis), so that DNA moves from the negative electrode to the positive electrode;Depending on the specific requirements of the 10 time with the electrophoresis experiment. Electrophoresis generally takes 1 to 3 hours. After electrophoresis power off, wearing disposable plastic gloves as far as possible to remove gel electrophoresis buffer with all stem, observed in the transmitted UV light of 254nm wavelength.

- Q: What are the building plywood used for?

- A kind of plywood for weather resistance, water resistance, durability of plywood, from here have advantages of high temperature resistance, steam treatment;The two kind of plywood is waterproof plywood, which can be soaked in cold water and soaked in short time;The three kind of plywood is moisture resistant plywood. It can be dipped in cold water for a short time and is suitable for indoor use at normal temperature. Used for furniture and general building purposes;

- Q: In the present construction, bamboo plywood or plastic board?

- The plastic board has good moisture resistance and is suitable for use in damp places. Each has its advantages. It depends mainly on where it is used.

- Q: What's the difference between plywood and plywood?

- The plywood is logs into veneer or by wood sliced veneer, with adhesive glued into three or more layers of sheet material, usually with odd veneer, and the fiber direction of adjacent plates perpendicular to each other and gluing.

- Q: What kind of glue do you want to make the plywood?

- Urea formaldehyde resin has low cost, light color, high hardness, oil resistance, mildew resistance, good insulation and temperature resistance, but its weather resistance and water resistance are poor. It is one of the thermosetting resins developed earlier. In 1924, the British developed melamine company, beginning in 1928, the sale of products, the mid 30s output reached thousand tons, in 80s the world's annual output has more than 1.5Mt.

- Q: What are the common thickness of bamboo plywood?

- Because of the high hardness, bending resistance and compressive resistance of bamboo plywood, steel formwork has been replaced in many use areas. Because bamboo is easy to cultivate, quick forest trees, three to five years will be cut down, can replace wood, therefore, the State Forestry Department policy supports the development of wood-based panels with bamboo as the main materials, has replaced the use of wood plates in a lot of places

- Q: Excuse me: is there a rubber board in the building material market that can replace glass instead of glass?

- You can use the PC boardPC board is a kind of high quality sheet made of polycarbonate, which is made of CO extrusion technology CO-EXTRUSION. Because of its surface covered with a high concentration of UV absorbers, in addition to anti UV characteristics, and can maintain long-term weather resistance, never fade. The PC board connection can be connected by special glue and effectively leak proof. The PC board generally refers to the PC sun board, the PC endurance board and the PC diffuser board, the PC lighting board. Product series are: PC plastic sheet, PC special plate, PC injection molding products, PC plastic bending forming, PC equipment cover, PC electronic and electrical enclosures, PC taxi protection column, PC explosion-proof shield, PC advertising board and so on.

- Q: What are the benefits of a plywood desk?

- The disadvantage is that it is too popular, and the more you use it, the more likely it is to devalue. Also, because of heavy and crisp plywood (mainly the glue itself heavy and brittle), its furniture screws, particularly by the connection of the regular activities of the loose leaf point tends to loose, so be sure to choose the regular manufacturers

- Q: What is covered plywood?

- Film covered plywood refers to the coated board, which is covered with a film on the base of the aluminum alloy. With high light film or super film, professional adhesive surface coating compound and into. The coated board has bright luster and can be chosen with many varieties, waterproof and fireproof. It has excellent durability (weather resistance, corrosion resistance, chemical resistance) and pollution resistance, and has excellent ultraviolet resistance. Different brands of coated plastic board, its substrate material and thickness of different film covered material and thickness are also different. Otherwise, the building covered with plastic film, made of poplar and other materials.

- Q: Will the ceiling be made of plywood or plasterboard?

- Gypsum board is characterized by light, heat insulation, non combustible, saw, nail, sound absorption, humidity control, beautiful, convenient construction. But poor moisture resistance, widely used in ceiling, partition wall.

Send your message to us

Office Furniture Commerical Desk/Table Solid Wood CMAX-BG029

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords