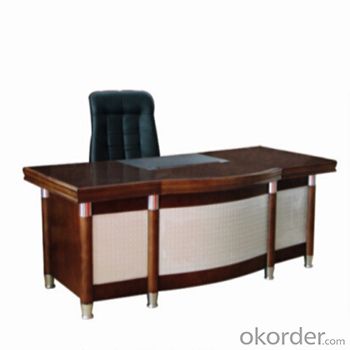

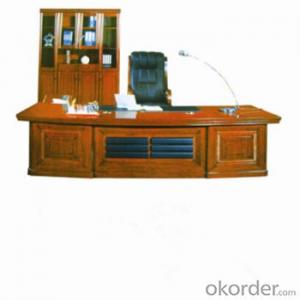

Office Commercial Furniture Boss Table with Modern Design

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Commercial Office Furniture – Modern Desk

This office desk employs a modern design in the widest range of colors. Water-resistant, anti-dust and anti-scratch, its sturdy structure and excellent surface finish are sure to impress.

Product Characteristics

- Modern Design and optional colors

- Resilient structure and excellent surface finish

- Water-resistant, anti-dust and anti-scratch

Product Photos

Office Boss Table with Modern Design Specification

Item | Content |

Name | Furniture |

Item Type | Office table |

Item Description | Office boss table |

Size | 3200*1150*760 |

Color | Reddish+Walnut |

Material | MDF+Veneer |

Frame | Wood |

MOQ | 20 sets |

Production Capacity | 5000 sets per months |

Product Features | Anti-water, Anti-dirty |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What about payment term?

A4: We accept 30%T/T in advance, with the balance before shipment. L/C at sight is also acceptable. Other payment term can be discussed with specific orders.

Q5: What is Melamine?

A5: Melamine is an organic compound that is often combined with formaldehyde to produce melamine resin, a synthetic polymer that is fire resistant and heat tolerant. The resin is a versatile material that has a highly stable structure. Its uses include whiteboards, floor tiles, kitchenware, fire retardant fabrics and commercial filters. Melamine can be easily molded while warm but will set into a fixed form, which makes it suitable for certain industrial applications. This compound is considered safe for normal uses.

Q6: What is MFC?

A6: MFC stands for ‘melamine faced chipboard’ and the vast majority of office furniture is manufactured with this material. There are a number of thicknesses used, but typically the industry standard is 25mm thick. Some budget ranges are 18mm thick. Essentially MFC is a picture (a photograph) of a real wood grain, repeatedly printed onto a Melamine film, and heat processed onto a sheet of chipboard. Most domestic furniture uses low density board, which is light. Most commercial grade furniture is made of a dense board – as it stops flexing and bending. MFC is available in a large number of plain colors and special finishes.

- Q: The difference between laminated lumber and plywood

- The biggest difference between the two is the formation of a single plate of the embryo, hot pressing and late processing. From the production point of view, LVL plate in the production and processing procedures to be more complex, plywood is relatively simple.

- Q: And as you kt PVC board

- PVC board is made of PVC as the raw material, and the section is honeycomb like mesh structure.

- Q: What is the difference between building formwork and bamboo plywood?

- What is the difference between building formwork and bamboo plywood?:Material: bamboo plywood with bamboo as the main raw materials; building template with pine and eucalyptus wood as the main raw materials;Weight: construction formwork is lighter than bamboo plywood;

- Q: What are synthetic plates, multilayer plates, plywood?

- The composite board is a wood board, fir board or multilayer plywood, the latter is light, easy to move, waterproof, and better synthetic board. Sometimes flatness is a little bit worse.

- Q: What's the market price of bamboo plywood?

- Bamboo plywood is made of bamboo material as the main structure and filling material! Because of the high hardness, bending resistance and compressive resistance of bamboo plywood, steel formwork has been replaced in many use areas! Because bamboo is easy to cultivate, quick forest trees, three to five years will be cut down, can replace wood, therefore, the State Forestry Department policy supports the development of wood-based panels with bamboo as the main materials, has replaced the use of wood plates in a lot of places! What specifications are required for different thicknesses?

- Q: What's the difference between plywood and fiberboard?

- Fiber board, with slab, wood shavings, branches and other waste materials, crushing, soaking, grinding into pulp, and then by wet molding, drying and other processes.

- Q: How long will it take for plywood to be free of formaldehyde?

- Formaldehyde removal by chemical methodSpray and other drug treatment easily cause two pollution, and may damage furniture, and activated carbon is physical adsorption, very safe, harmless, mildew proof, antiseptic effect on furniture.

- Q: 9 mm splint what specifications, length and width of each is how much?

- Plywood, also known as plywood, the line is commonly known as fine core board. Made of three or more layers of a single sheet of a millimeter thick veneer or glued. Handmade furniture is the most commonly used materials.

- Q: How much is the wall of punched plywood one square metre?

- Light steel keel frame, plywood surface, single-sided 85 yuan / square, double-sided 115 yuan / square meter. Plywood is not suitable for partitions. One is the fear of water, water absorption will become uneven.

- Q: What is the density of the oil resistant rubber sheet?

- This problem no one can answer you, there are many kinds of oil resistant rubber, nitrile rubber, chloroprene rubber, acrylic rubber, fluorine rubber, different kinds of density vary greatly, even with a rubber formula, different density are also different

Send your message to us

Office Commercial Furniture Boss Table with Modern Design

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords