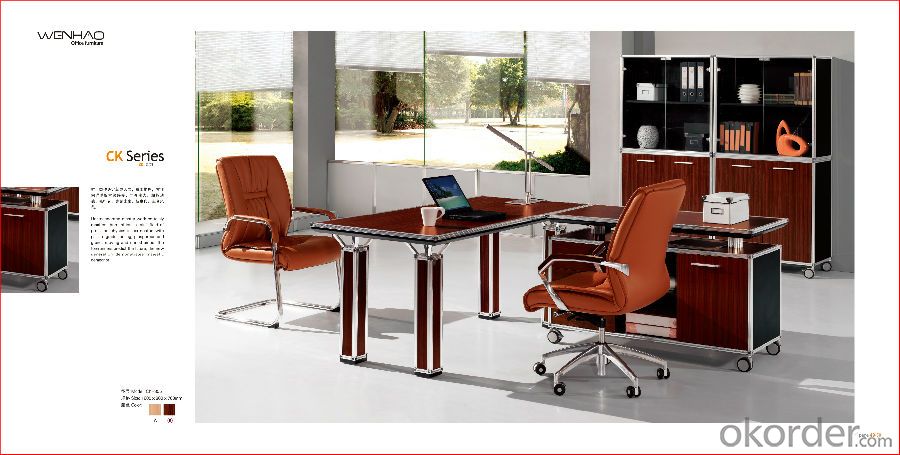

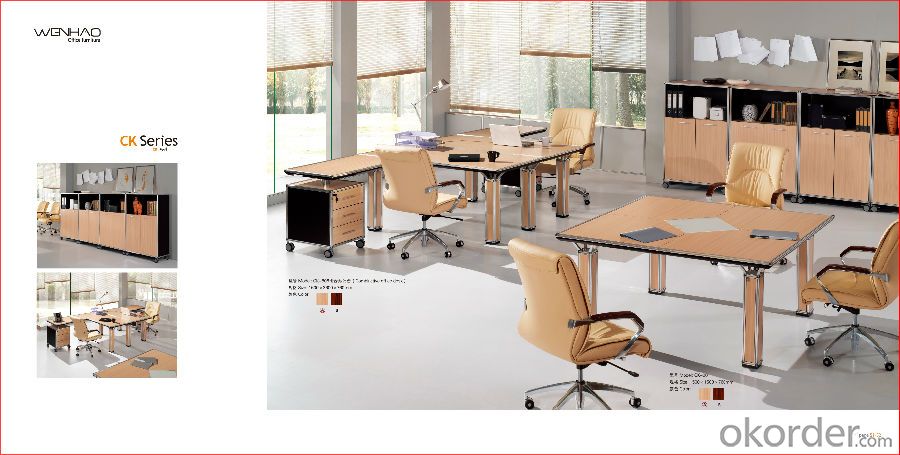

Office desk model-10

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

| Descrpition: | |

| Model: | 12ET17 |

| Brand : | HOMEFELT Or OEM |

| Size: | 1800x800x760MM |

| Any Siz is available | |

| Material: | Good Quality MFC |

| Wood Thickness: | 25MM |

| Structure: | Main Table |

| Side Table and Movable Pedestal | |

| Style: | Modern |

| Export Years: | Over 1 years |

| Exported Countries: | Europe,Mid-East and America |

| MOQ: | One Containers mixed loading with different models at least 50pcs |

| Packaging: | Knockdown or Assembled Packaing as requests |

| Good quality Carton with printing as requests | |

| Payment Term: | T/T, LC At sigh, WESTERN UNION, MONEYGRAM or Cash |

| Trade Term: | FOB or EXW |

- Q: Building engineering wood plywood can turn over several times?

- Architectural templates are hierarchical,Good template, in theory can use about 10 times, of course, the actual use can not reach, generally can use about 6 times

- Q: Which is good, Take Sakaki template?

- Toughness: the toughness of bamboo plywood is better;Number of times: ordinary bamboo plywood used 8 times, wooden template in 6 times;Habits: more wood templates in the south, and more bamboo plywood in the north;

- Q: How long will it take for plywood to be free of formaldehyde?

- Removal of formaldehyde from soil:300 grams of black tea bubble hot tea, two washbasin water, put into the living room, and window ventilation, 48 hours, indoor formaldehyde content will fall by more than 90%, the pungent odor is basically eliminated.Elimination of formaldehyde harm by odor removal by plantsModerate and low pollution can choose plant decontamination: general indoor environmental pollution in mild and moderate pollution, pollution value in the national standard of 3 times below the environment, using plant purification can achieve better results. Choose and place plants according to the size and size of the room. Under normal circumstances, 10 square meters of room, 1.5 meters tall plants, put two pots more appropriate.

- Q: Pressing process of plywood

- Plywood is one of the commonly used furniture materials. It is a kind of artificial board. A set of veneers usually glued together in a direction perpendicular to the direction of the adjacent layers of wood. Usually the table plate and the inner plate are symmetrically arranged on both sides of the central layer or the core of the plate. A single slab made of glued sheets that are Criss crossed in the direction of wood grain. The number of layers is generally odd, and even a few are even. The physical and mechanical properties of the vertical and horizontal directions are less different. There are three commonly used plywood, plywood etc.. Plywood can improve wood utilization, and it is a main way to save wood. They can also be used in aircraft, ships, trains, automobiles, buildings and packing boxes.

- Q: The ABS rubber plate is thicker. What tool can you use to cut it?

- Also known as the knife knife or wallpaper knife, is a kind of art and craft knife, mainly used for cutting soft things, for the plastic knife handle and a blade is composed of two parts, for pulling type structure.

- Q: What are the differences between LVL, LVB, plywood and plywood? Is it divided by the use of it, or is it just a different name?!

- Name is not the same, the structure of the plate is not the same, the pressure and the degree of seed is not the same.

- Q: What is the difference between multi-layer solid wood flooring and plywood?

- Plywood is made of three or more than three layers of single plate juxtaposed with each other vertically and glued according to the principle of symmetry. Plywood is usually divided into four levels: first, two, three, etc., one and two other senior product is mainly used for building decoration, furniture, musical instruments and appliances such as shell, the material and the machining precision is high; three supplies and goods into which we commonly used for low-level architectural decoration, packaging materials such as plywood, the material processing precision is low, the price is relatively cheap.

- Q: The difference between plywood and plywood

- Multilayer board is plywood refers to more than two layers of sheet by bonding in the field of building materials, decoration materials, five refers to the three splint splint, 9 PCT board, 12 board, wooden board and plywood; not only containing these plates, at the same time with MDF, particleboard and other a series of adhesive glued board, including decorative plate with a decorative surface paste such as decorative plywood (such as walnut or cherry, ashtree, Sapele panel), double-sided moisture-proof plate and sandwich plates etc..

- Q: What is covered plywood?

- As the name suggests, the plywood is covered with film, and the resin coated board is mainly used for building and pouring cement. The film is difficult to bond with cement

- Q: Can the insulating rubber sheet be towed by water?

- It can be towed by water. The insulating rubber plate is waterproof and won't be corroded by water.

Send your message to us

Office desk model-10

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords