ExecutiveTable Office Desk MDF Hight Quality Wood Melamine/Glass D45

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

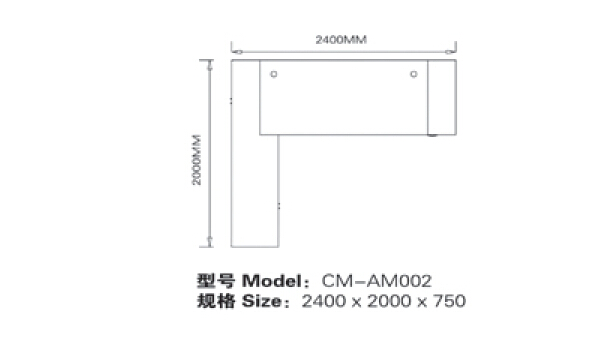

| Type: | Office Furniture | Specific Use: | Office Table | Wood Style: | Metal,MDF,Melamine |

| Certification | ISO9001 Quality & Enviroment | Size | 2800*2800*1050 | Advantages | Attractive Design ,Competitive Price |

| Assembling Guide | Available | customization: | Yes | Specific Uses | Office Desk ,Executive Desk |

| MOQ | 5 sets | Payment Term | T/T,L/C | Delivery Time | 15-20 days |

We specialized in office desk and office seating .Our factory has been engaged in office furniture for more than 10 years. Our factory is well-known in the high quality and competitive price of our products. Therefore, we completed in specifications and win warm praise from customers. In addition, the design of our products is deft, modern and beautiful. There are many types and colors for your selection. Our goods are easy and simple to handle and durable in use.

Welcome any questions!

- Q: What is the thickness requirement of the insulation board in the distribution room?

- General appearance requirements:1, the insulation plate edge neat, no crack.2, bubble per square meter range, the area of less than 1 square centimeter of bubble may not exceed 5. The spacing between any two bubbles shall not be less than 40mm.3. The depth and length of the impurity shall not exceed 1/6 of the thickness of the insulating plate.

- Q: What is the difference between solid wood composite board and plywood?

- ) material difference: multi-layer solid wood flooring to take into account the different "anisotropy", so that the production process can fully balance the "internal stress", in addition, we need to consider for the thermal conductivity of ground bearing capacity for geothermal; and general plywood or plywood over this.

- Q: And as you kt PVC board

- It is a kind of vacuum blister film. It is used for surface packing of various panels, so it is also called decorative film and adhesive film. It is applied to many fields such as building materials, packaging, medicine and so on. Among them, the building materials industry accounted for the largest proportion, 60%, followed by the packaging industry, as well as other small range of applications. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foaming board.

- Q: Is solid wood composite floor plywood made of plywood?

- Solid wood composite flooring is confused with plywood by consumers. In fact, the use of the two different, different physical indicators, selection of materials, crafts are more different.

- Q: What's the difference between a plywood press and a panel press?

- Hot pressing veneer, veneer veneer single double hot press, hot press, hot pressing system features: fast heating, heating system, heat conduction system of light carefully designed, low energy consumption, heat conduction mechanism design is reasonable, uniform; parts processing precision, wide adjustment range of process parameters, control process design is reasonable, can meet the requirements process for the production of veneer.

- Q: Which is good, Take Sakaki template?

- Strength: bamboo plywood with bamboo polishing sheet, and woven bamboo, short and long curtain curtain, in the template group embryo, with long and short curtain curtain Jingwei staggered, and then combined with high temperature and high pressure, high strength; wood template is pine bark and eucalyptus veneer layers of glue after the first cold pressing and hot pressing molding, two;

- Q: How are the plywood made?

- Plywood usually refers to three plywood or multilayer board, that is, with the same thickness of two or more layers of wood veneer and glue high temperature suppression. Usually, the odd layer single plate is used, and the fiber direction of the adjacent layer single plate is perpendicular to each other.

- Q: What kind of wood is plywood made of?

- There are three common types of plywood plywood, plywood etc.. Plywood can improve wood utilization, and it is a main way to save wood.

- Q: What is bamboo plywood?

- Bamboo plywood is made of bamboo material as the main structure and filling material.

- Q: What is the production process of bamboo plywood?

- The four roller coating machine soluble phenolic resin on bamboo roller coating glue water, the quantity is 300, 350g/ square meters (double). Adhesive can be added 1%--3% flour, soy flour and other fillers. The filling agent causes the bamboo sheet to form a gum film on the surface after gluing, which is difficult to produce flowing glue when hot pressing, and the brittleness of the adhesive layer can be improved after curing.

Send your message to us

ExecutiveTable Office Desk MDF Hight Quality Wood Melamine/Glass D45

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords