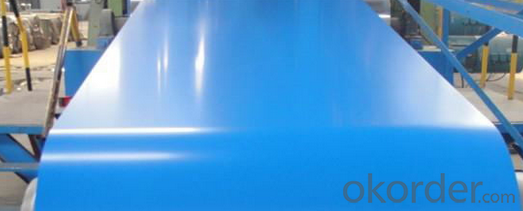

NICE COLOR ALU-ZINC STEEL SHEET IN COIL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

Nice alu-zinc steel sheet in coil ,with Gi as base metal after pretreatment ( degrease and chemical treatment) and liquid dope with several layers of color then after firing and cooling finally the plate steel is called Pre-painted galvanized steel is good capable of decoration ,molding corrosion resistance

Product Features

Excellent process capability

Smooth and flat surface

Workability durability

Excellent heat resistance performance

High Strength

Good formability

Good visual effect

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

1. How long will we receive the goods ?

45days after receiving workable L/C

2. how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: What are the different types of steel coil surface treatments for indoor applications?

- There are several different types of steel coil surface treatments that are suitable for indoor applications. These treatments are designed to enhance the appearance, durability, and performance of the steel coil in various indoor environments. Some of the common surface treatments for indoor applications include: 1. Galvanized Coating: This is one of the most popular surface treatments for indoor applications. Galvanizing involves applying a layer of zinc to the steel coil, which provides excellent corrosion resistance and protects the steel from environmental elements. 2. Pre-painted Coating: Pre-painting the steel coil with a specific color or finish is another common surface treatment for indoor applications. This coating not only improves the aesthetics of the steel, but also provides additional protection against corrosion and wear. 3. Powder Coating: Powder coating is a process where a dry powder is electrostatically applied to the steel coil and then cured under heat. This treatment creates a durable and attractive finish that is resistant to chipping, scratching, and fading. Powder coating is available in a wide range of colors and textures, making it a versatile choice for indoor applications. 4. Vinyl Coating: Vinyl coating is a type of surface treatment that involves applying a layer of PVC (polyvinyl chloride) to the steel coil. This coating provides excellent chemical resistance and protects the steel from moisture, abrasion, and UV radiation. Vinyl coating is commonly used in indoor applications where chemical exposure or moisture resistance is a concern. 5. Laminated Coating: Laminating the steel coil involves bonding a thin layer of plastic or other material to the surface of the steel. This treatment enhances the appearance of the steel and provides additional protection against scratches, stains, and fading. Laminated coatings are available in various colors and patterns, making them suitable for indoor applications where aesthetics is a priority. It is important to consider the specific requirements of the indoor application when choosing a steel coil surface treatment. Factors such as corrosion resistance, durability, aesthetics, and budget should be taken into account to ensure the best possible performance and longevity of the steel coil in indoor environments.

- Q: In pounds per square inch what is the tensile strength of strong steel?

- Depends on what you mean by strong steel. Typically the ultimate strength/yield point of steel used for building structures (beams, columns, joists, plates) is in the range of 36,000 to 50,000 psi. The strength is specified by the designer (in the U.S.) by its ASTM designation. e.g. ASTM A36, A572, A500, A307, A325 ... A36 is typical mild steel, A572 Grade 50 (50,000 psi) is often called high-strength Really high strength steels such as pre-stressing strand can have ultimate strengths more than 10 times these values.

- Q: How do steel coils contribute to sustainability in construction?

- Several factors contribute to the sustainability of construction when it comes to steel coils. To begin with, steel is an incredibly durable material with a long lifespan. Its use in the construction of structural components like beams, columns, and frames ensures the stability and strength of buildings. This durability translates to reduced maintenance requirements and a longer service life for structures. As a result, the need for frequent repairs or replacements is diminished, leading to a decrease in the overall environmental impact associated with material waste and energy consumption. Moreover, steel is highly recyclable. Steel coils can be easily recycled and reused in new construction projects. The recycling process for steel has a significantly lower environmental impact compared to the production of new steel. By incorporating recycled steel coils into construction projects, the demand for new steel production is reduced, resulting in lower greenhouse gas emissions and a smaller carbon footprint. This approach helps conserve natural resources, reduces the extraction of raw materials, and minimizes energy consumption in steel production. Additionally, steel is an ideal material for off-site prefabrication. This means that steel coils can be manufactured in controlled environments in factories, minimizing construction waste and improving construction efficiency. Prefabricating steel coils reduces on-site material waste and decreases the need for transportation of construction materials. Consequently, this reduces air pollution and energy consumption during construction. Furthermore, steel's high strength-to-weight ratio allows for lighter and more efficient structures. By using steel coils, construction projects can optimize material usage, resulting in reduced material consumption and lessening the overall environmental impact. The lightweight nature of steel coils also facilitates easier transportation, reducing fuel consumption and associated emissions during delivery. In summary, steel coils contribute to the sustainability of construction through their durability, recyclability, prefabrication capabilities, and high strength-to-weight ratio. By utilizing steel coils, construction projects can minimize waste, conserve resources, reduce energy consumption, and decrease the environmental impact, ultimately promoting a more sustainable built environment.

- Q: How are steel coils used in the production of automotive stampings?

- Automotive stampings heavily rely on steel coils, which are vital for their production. These coils are typically crafted from top-notch steel and are cut into specific measurements to meet automotive manufacturers' specifications. To begin the process of using steel coils for automotive stampings, the steel must first be uncoiled. This task is accomplished by a machine called a decoiler, which unwinds the coil and feeds it into the stamping machine. By utilizing the decoiler, a consistent supply of steel is ensured for the stamping process. Once the steel coil is unwound, it is inserted into the stamping machine. Equipped with a die specifically designed for shaping the steel into desired automotive components, the machine commences its work. The die is capable of creating intricate and accurate shapes, such as car body panels, doors, fenders, and structural elements. By applying force, the stamping machine presses the steel coil against the die, forming it into the desired shape. The high-quality steel utilized in the coils guarantees that the stamped components possess the necessary strength and durability required for automotive applications. Following the stamping process, the stamped components undergo a thorough inspection to assess their quality and precision. Any flaws or defects are identified and rectified prior to the components being sent for further processing, including painting, welding, or assembly. In conclusion, steel coils are of utmost importance in the production of automotive stampings. They provide a continuous supply of high-quality steel, which is skillfully shaped into precise and long-lasting automotive components. The utilization of steel coils ensures that the automotive stampings adhere to the required standards for strength, durability, and precision.

- Q: How are steel coils used in the production of metal cabinets?

- Steel coils are a vital element when producing metal cabinets, as they consist of thin steel sheets tightly wound into coils. To begin using steel coils for metal cabinet production, the first step is to uncoil them. This involves unwinding the coil and feeding the steel sheet into a machine that cuts it to the desired length, depending on the size and dimensions of the metal cabinet being manufactured. Once the steel sheet has been cut, it undergoes a process known as blanking. This entails cutting out the necessary panels and parts for the metal cabinet, including the sides, top, bottom, and doors. The blanking process is typically carried out using a stamping press or laser cutting machine to ensure precise shaping of the steel sheet. Following the blanking process, the individual panels are then formed and shaped using a series of bending and forming machines. These machines apply pressure and force to the steel panels, bending them into the desired shape and creating the necessary angles and curves required for the metal cabinet design. After the panels have been formed, they are typically joined together using welding or fastening techniques. Welding involves using heat to fuse the edges of the steel panels together, while fastening techniques may involve the use of screws, bolts, or rivets to securely hold the panels in place. In summary, steel coils are essential in the production of metal cabinets as they provide the raw material for creating the individual panels. The use of steel coils allows for greater flexibility and efficiency in manufacturing metal cabinets, enabling mass production and customization of cabinet designs.

- Q: What are the different types of coil recoiling machines?

- The different types of coil recoiling machines include manual coil recoilers, semi-automatic coil recoilers, and fully automatic coil recoilers.

- Q: should I shoot Herters .308 steel cased ammo in my Remington 7400.and why shouldn't I?

- Won't hurt anything, but do be aware, if you're plinking with it, that FMJ (and maybe even steel core), cheap ammo offers more chance of penetration and ricochet so be sure you've got a good back-stop so you know where those rounds wind up.

- Q: How do steel coils contribute to energy efficiency in lighting?

- Steel coils do not directly contribute to energy efficiency in lighting. Steel coils are typically used in the manufacturing of various electrical and electronic appliances, including lighting fixtures. However, the energy efficiency in lighting primarily depends on the type of light source used. The energy efficiency of lighting is typically determined by the type of light bulb or fixture used, such as incandescent, fluorescent, LED, or halogen. Each of these light sources has different energy consumption characteristics. Steel coils, on the other hand, are primarily used for structural support, heat dissipation, and protection in lighting fixtures. They are not directly involved in the energy efficiency of the lighting system. However, steel coils can indirectly contribute to energy efficiency in lighting by providing strong and durable support to the lighting fixtures. This allows for reliable and long-lasting installations, minimizing the need for frequent maintenance and replacements. A well-supported lighting system ensures optimal performance and reduces any energy wastage or inefficiencies that may arise from loose or unstable fixtures. Additionally, steel coils can also be utilized in the manufacturing of reflectors or housings for lighting fixtures, which can help enhance the overall efficiency and distribution of light. By effectively reflecting and directing the light output, the utilization of energy and illumination can be optimized, reducing any potential energy waste. While steel coils themselves do not directly impact the energy efficiency of lighting, their use in the construction and support of lighting fixtures can indirectly contribute to a more energy-efficient lighting system.

- Q: What could the impurities in steel wool be?And why are they there?Thanks for your help :)

- Impurities in steel wool would be of the elemental type. I'm sure steel wool is a mixture of different low grade not good for much of anything else materials. There may be excessive impurities such as lead, cobalt, boron, aluminum etc... in the steel wool. There may also be solvent residue on the wool i.e cleaner, lubricant etc.. I'm sure every batch is different - I know the iron level is high thats what makes them rust quickly.

- Q: What are the common surface finishes available for steel coils?

- Steel coils offer various surface finishes to meet specific application and aesthetic needs. One commonly used finish is hot-dip galvanized, which involves zinc coating the coil for excellent corrosion resistance in outdoor settings exposed to moisture and harsh weather. Another popular option is electro-galvanized, achieved by electroplating a thin zinc layer onto the coil. While it provides good corrosion resistance, it is not as durable as hot-dip galvanized. In addition, steel coils can be coated with paint or polymer to enhance appearance and provide extra corrosion protection. The coatings are available in different colors and finishes, such as matte or glossy, catering to specific aesthetic requirements. Furthermore, steel coils can undergo a mill finish, leaving them raw and untreated for future processing or coating. Other surface finishes include stainless steel, achieved through passivation to enhance corrosion resistance, and brushed or polished finishes for decorative purposes. Ultimately, the choice of surface finish depends on factors like intended use, environmental conditions, and desired appearance. Each finish offers unique advantages and characteristics.

Send your message to us

NICE COLOR ALU-ZINC STEEL SHEET IN COIL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords