New Type ZA/ZB Manufactured Homes Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 140 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Type ZA/ZB Manufactured Homes

ZA house:

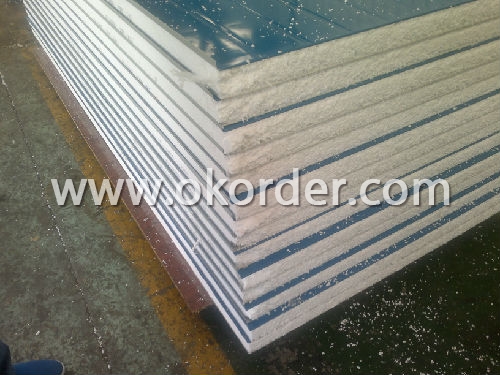

1. The house is made of galvanized structure and rustproof color steel sandwich panel as wall and roof.

2. Six skilled workers can finish 50m2 in 8 hours.

3. The house has waterproof structure and fireproof insulation material, such as EPS, rock wool and glass wool.

4. The house can resist heavy wind load of 0.5KN/M2 and 7-8 degree seismic intensity.

ZB house:

1. Air circulation between roof and ceiling creates a better insulation for room inside. Roof is color steel sheet and ceiling is color steel sandwich panel.

2. Six skilled workers can finish 50m2 in 8 hours.

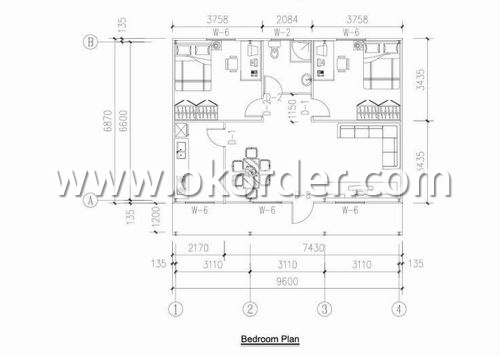

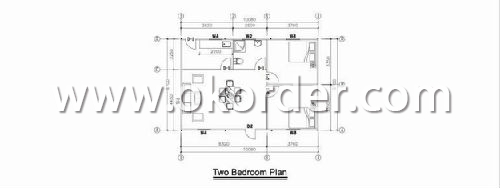

3. The size and layout can be designed as per customers’ requirements.

4. The house can resist heavy wind load of 0.35KN/M2 and 7 degree seismic intensity.

Items | ZA house | ZB house |

Life span(year) | 10-15 | 8-10 |

Advantage | Size and layout can be designed as per client's requirements, max span 12m. | Compared with ZA: 1.Less steel structure. 2. Double layer roof makes it cooler inside. 3.It's not so stronger than ZA cause the wall panels support roof system |

Wind load | 0.5KN/m2 | 0.35KN/m2 |

Structure | galvanized steel structure( C type steel ) | painted steel tube |

Wall & roof | EPS / rock wool / glass wool sandwich panels (50/75/100mm or customized) | EPS / rock wool / glass wool sandwich panels (75mm/100mm or customized) |

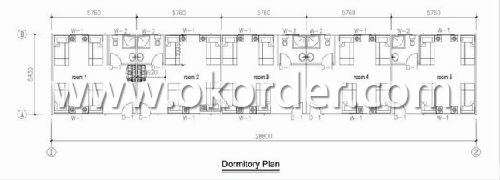

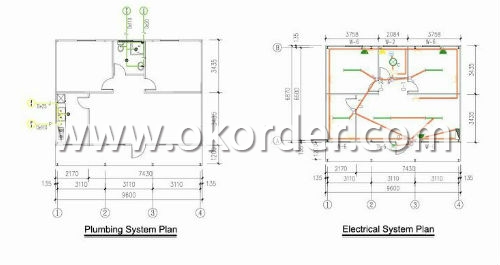

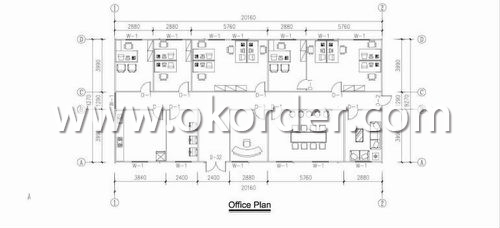

Production and Layout Plan of Type ZA/ZB Manufactured Homes

All of the items are made of steel structure and color steel sandwich panel.

Layout plan of the type ZA/ZB modular homes

Packaging & Delivery of Type ZA/ZB Manufactured Homes

According to the quantity, all the parts are packed separately in suitable ways and loaded by containers. One 40HQ container can load about 160m2 considering 75mm thickness panel for roof and wall.

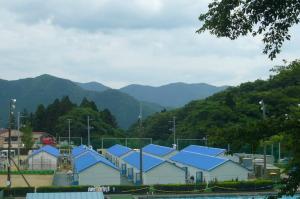

Usage/Applications of Prefab House / Modular Homes

It is widely used in offices, sales offices, classrooms, shops, cafes, exhibition galleries, hospitals, dormitories, canteens, industrial plants, warehouses, parking lots, simple sheds, lean-room, movable guard post, modular villa, site temporary facilities etc.

Installation Steps of Prefab House / Modular Homes

1. Trenching

2. Foundation, brick foundation or concrete foundation

3. Install the steel frame

4. If the structure is multi-layer, to install the prefabricated floor

5. Color plate installation

6. First floor terrace installation

7. Install windows and doors

8. Interior decoration

- Q: 100 square meters villa size how to calculate?

- showing the villa style, and the process is not complicated, Laying roofing materials on a triangular roof truss

- Q: What is the difference between a house and a villa?

- the house belongs to the class villa, but the quality of living or lower than the villa, the villa into the door all belong to their own space, and independence. Bungalows generally a layer of 2, there is a flat area

- Q: Buy second-hand villa need to pay attention to what?

- Whether it is the plot of the internal landscape or landscape and other external resources are the value of product preservation and value-added value

- Q: What kind of house to be a villa?

- can also be translated into" manor "," castle ", a poetic house .In fact, the current domestic real estate market sales of most of the" villa "is not Villa, but HOUSE.

- Q: Why is someone called him called "Do not wild?

- generally refers to the beautiful scenery in the landscape, away from the hustle and bustle

- Q: What kind of villa is good?

- One said that the development of the villa community must have a good environment, there is sufficient green area and rich landscape content

- Q: What is the most important thing to design a villa?

- and some very few people involved in the space but instead left a lot of space

- Q: What does the villa mean?

- Is home to enjoy the living outside the home, is the second place rather than the first home

- Q: What is a stacked villa?

- Laminated villas, also known as superimposed villas. As the name suggests, is the villa in the form of superposition of the superposition of the layer to households

- Q: What is the villa district management model

- each post set. Each department, each post name is for the interests of the owners, are in order to more efficient

1. Manufacturer Overview

| Location | Beijing, China |

| Year Established | 1965 |

| Annual Output Value | Below US$1 Million |

| Main Markets | South Africa; Mid East; Eastern Europe; North America; South-east Asia; North Africa |

| Company Certifications | ISO9001-2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 35-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | High |

Send your message to us

New Type ZA/ZB Manufactured Homes Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 140 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords