Aluminum Strips Lowes New Product Coil Aluminum Composite Panel Roller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Stable aluminium is created when hydrogen fuses with magnesium, either in large stars or in supernovae. It is estimated to be the 14th most common element in the Universe, by mass-fraction. However, among the elements that have odd atomic numbers, aluminium is the third most abundant by mass fraction, after hydrogen and nitrogen.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

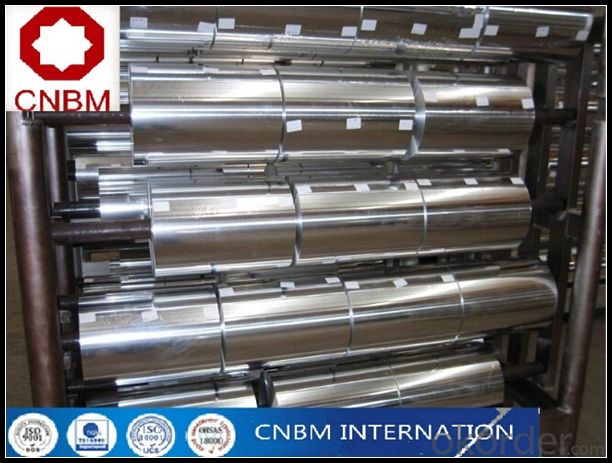

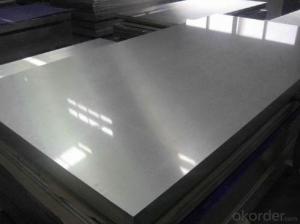

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Would you like to buy a sensor for measuring the thickness of aluminum ribbon?

- Have the following characteristics:Characteristic:1, according to the measurement environment, measurement methods, customized measurement program, the highest linearity 1um, the highest resolution 0.3um;2, high-speed online measurement, the highest sampling frequency of 9400Hz;3 and multi-point measurement, an industrial computer can control up to 63 thickness measurement points;4, the closed-loop control can be realized with the field devices to achieve seamless scene closed-loop control, and field equipment linkage, alarm and other functions, and can be linked to the ERP system;5. It is not sensitive to the material and color of the tested object, and the change of color has no effect on the result of measurement;6, the system is mature and stable, the algorithm has higher reliability, and the new algorithm can be customized according to the specific measurement environment to meet the special requirements;7, high efficiency, save manpower and material resources, improve production quality.

- Q: Is it possible to utilize aluminum strips for constructing a decorative railing system for residential or commercial purposes?

- <p>Yes, you can use aluminum strips to create a decorative railing system for your home or business. Aluminum is a popular choice due to its durability, low maintenance, and resistance to rust and corrosion. It can be easily shaped and painted to match the aesthetic of your property. Ensure that the railing meets local building codes and safety standards, and consider consulting with a professional to design and install the system for optimal safety and appearance.</p>

- Q: What types of aluminum strip are best suited for outdoor or exterior applications?

- <p>Yes, certain types of aluminum strip are particularly suitable for exterior applications. These include aluminum strips with high corrosion resistance, such as those with a 3003 or 5052 alloy composition. They are often coated with a protective layer, such as anodizing or a paint finish, to enhance their durability against weather conditions. Additionally, aluminum strips with a thicker gauge are more resistant to denting and wear, making them ideal for exterior use. It's also important to consider the specific environmental conditions of the application, such as exposure to saltwater or extreme temperatures, to select the most appropriate aluminum strip for the job.</p>

- Q: What is the standard thickness for aluminum strip roofing materials?

- <p>The recommended thickness for aluminum strip roofing varies depending on the specific application and local building codes. Generally, aluminum strip roofing is available in thicknesses ranging from 0.018 to 0.032 inches (0.46 to 0.81 mm). For residential applications, a thickness of 0.024 to 0.028 inches (0.61 to 0.71 mm) is commonly used, while commercial buildings might require a thicker strip, around 0.032 inches (0.81 mm) for added durability and longevity. Always consult with a roofing professional or follow local building codes to determine the appropriate thickness for your specific project.</p>

- Q: Is it possible to utilize aluminum strips as a material for insulating interior walls?

- <p>Aluminum strips are not typically used for interior wall insulation. Insulation materials are designed to provide thermal resistance, and aluminum is a good conductor of heat, which makes it unsuitable for insulation purposes. Common insulation materials include fiberglass, mineral wool, and polyurethane foam, which are effective at reducing heat transfer. Aluminum strips might be used in construction for other purposes, such as reinforcement or as a vapor barrier, but not for insulation.</p>

- Q: What types of aluminum strips are known for their durability?

- <p>Yes, there are several types of aluminum strips known for their durability. One of the most durable types is 7075 aluminum, which is an alloy that offers high strength and is commonly used in aerospace applications. Another durable option is 6061 aluminum, which is a heat-treatable alloy with good mechanical properties and is often used in construction and transportation. Additionally, 3003 aluminum is known for its corrosion resistance and is used in applications where durability against weathering is important. The durability of aluminum strips can also be enhanced through various surface treatments and coatings.</p>

- Q: Is it possible to utilize aluminum strips in environments with high temperatures?

- <p>Aluminum strips can be used in high-temperature environments, but their performance and longevity depend on the specific conditions and the alloy type. Pure aluminum has a melting point of 660掳C (1220掳F), but aluminum alloys can be designed to withstand higher temperatures. For instance, some aluminum alloys are used in aerospace and automotive applications where they experience high temperatures. However, prolonged exposure to high temperatures can lead to material degradation, so it's crucial to select the right alloy and consider the temperature limits specified by the manufacturer for the intended application.</p>

- Q: What types of metal sheets are better suited for specific applications and conditions?

- <p>Yes, different types of metal sheets are better suited for specific applications and conditions. For instance, stainless steel is excellent for food processing and marine environments due to its corrosion resistance. Aluminum is lightweight and conducts heat well, making it ideal for cookware and heat exchangers. Galvanized steel is used in construction for its rust protection. Copper is known for its high thermal and electrical conductivity, suitable for electrical wiring and plumbing. Each metal has unique properties that make it suitable for particular uses, and the choice depends on factors like strength, durability, weight, and cost.</p>

- Q: What types of aluminum strips are best suited for solar panel applications?

- <p>Yes, there are specific types of aluminum strips that are particularly suitable for use in solar panels. These include high-purity aluminum strips with low iron content, which are known for their excellent electrical conductivity and corrosion resistance. They are often used as busbars in solar cells to collect and transmit the generated electrical current. Additionally, aluminum strips with a high-strength alloy composition are used for structural support and frame components in solar panels due to their lightweight and durability. These aluminum strips are engineered to withstand harsh environmental conditions and maintain their integrity over the long lifespan of the solar panel.</p>

- Q: This question asks for criteria to determine if an aluminum strip is still safe and effective for use.

- <p>To determine if your existing aluminum strip is still suitable for use, you should check for any visible signs of damage such as cracks, bends, or corrosion. Ensure that the strip is clean and free from any contaminants that might affect its performance. If the strip is part of a mechanical system, check its dimensions to ensure it hasn't warped or lost its shape. Additionally, consider the strip's age and the conditions it has been subjected to, as prolonged exposure to certain elements can degrade its properties. If you're unsure, consult the manufacturer's guidelines or have a professional assess the strip's integrity.</p>

Send your message to us

Aluminum Strips Lowes New Product Coil Aluminum Composite Panel Roller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords