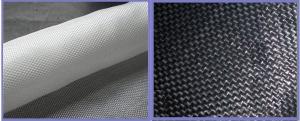

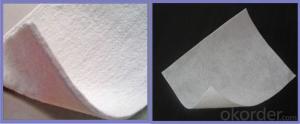

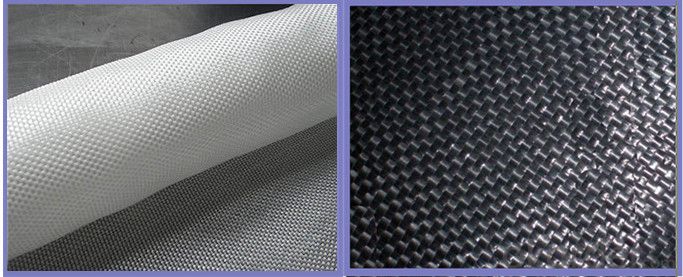

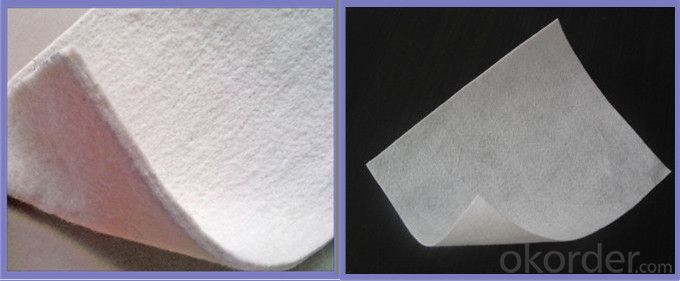

Géotextile Brico Depot Needle Punched Nonwoven Geotextiles for River Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Needle Punched Nonwoven Geotextiles Used for River Construction:

-Reinforced filtering road geotextile

-quality:good quality

-strength:high strength

-tencity:well

-packagel:woven bags

TDS of Needle Punched Nonwoven Geotextiles Used for River Construction:

Item | Art No. | CMAX030101 | CMAX030102 | CMAX030103 | CMAX030104 | CMAX030105 | CMAX030106 | CMAX030107 | CMAX030108 | CMAX030109 | CMAXPLB030110 | CMAX030111 |

Unit weight, g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 | |

Weight tolerance, % | -8 | -8 | -8 | -8 | -7 | -7 | -7 | -7 | -6 | -6 | -6 | |

Thickness, ≥mm | 0.9 | 1.3 | 1.7 | 2.1 | 2.4 | 2.7 | 3.0 | 3.3 | 3.6 | 4.1 | 5.0 | |

Break strength, ≥kN/m | 2.5 | 4.5 | 6.5 | 8.0 | 9.5 | 11.0 | 12.5 | 14.0 | 16.0 | 19.0 | 25.0 | |

CBR burst strength, ≥kN | 0.3 | 0.6 | 0.9 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 2.7 | 3.2 | 4.0 | |

Tear strength, ≥kN | 0.08 | 0.12 | 0.16 | 0.20 | 0.24 | 0.28 | 0.33 | 0.38 | 0.42 | 0.46 | 0.60 | |

Width tolerance, % | -0.5 | |||||||||||

Break elongation, % | 25-100 | |||||||||||

EOS O90, mm | 0.07-0.2 | |||||||||||

Vertical permeability coefficient, cm/s | K×(10-1-10-3)K=1.0-9.9 | |||||||||||

- Q: How do geotextiles help with reinforcement of geogrid retaining walls?

- Geotextiles help with reinforcement of geogrid retaining walls by providing additional strength and stability. They are placed between the geogrid and the backfill soil, acting as a separation layer. Geotextiles prevent the migration of fine particles from the soil into the geogrid, reducing the risk of clogging and maintaining the proper functioning of the wall. Additionally, they distribute the load more evenly across the geogrid, enhancing its tensile strength and overall performance.

- Q: How to build a good geotextile sales team

- Any industry needs talent, geotextile sales staff do not need a high degree of education, can work hard on the line, I am specializing in the production of geotechnical materials, wish smooth

- Q: Geotextile thinnest how many grams

- 80-100g, I am specializing in the production of geotextile geomembrane, wish smooth

- Q: Geotextile manufacturers are what industry

- Geotextile manufacturing enterprises are textile and leather industry

- Q: Can geotextiles be used in green wall construction?

- Yes, geotextiles can be used in green wall construction. Geotextiles provide several benefits such as soil containment, erosion control, and moisture retention, which are essential for the successful establishment and growth of plants in green walls. They can help improve the structural integrity of the wall, prevent soil erosion, and provide a suitable environment for plant roots to grow and thrive.

- Q: Construction of composite geotextile

- Geotextile as a protective layer of geomembrane, so that the protection of impermeable layer from damage. In order to reduce the UV radiation, increase the anti-aging properties, it is best to use the laying method. Construction, the first use of smaller diameter sand or clay to find the base surface, and then laying geomembrane. Geomembrane should not be stretched too tight, buried at both ends of the soil part of the corrugated, and finally in the shop on the geomembrane with a fine sand or clay shop layer of 10cm or so excessive layer. Puzzle 20-30cm stone (or concrete prefabricated block) for the anti-Chong protective layer. Construction, should try to avoid the stones directly hit the geomembrane, the best side of the film side of the protective layer of the construction. Composite geomembrane and the surrounding structure should be connected with expansion bolts and steel plate pressure bar anchorage, the connection site to brush the emulsion asphalt (2mm thick) bonding, to prevent the occurrence of leakage.

- Q: What are the materials used in geotextile production?

- The materials commonly used in geotextile production include polyester, polypropylene, and polyethylene. These synthetic fibers are chosen for their durability, resistance to environmental factors, and ability to provide strength and stability in various geotechnical applications.

- Q: Pvc tube outsourcing geotextile, how to count how much geotextile

- Calculate the circumference of the bottom of the pipe by the diameter of the pipe, and the length of the pipe is multiplied by the length of the pipe, which is the area of the geotextile. Huazhi geotechnical materials manufacturers to answer your questions

- Q: What are the different weight options available for geotextiles?

- Geotextiles typically come in a range of weight options, which can vary from lightweight to heavyweight. These weight options are measured in terms of grams per square meter (gsm) or ounces per square yard (oz/yd²). The specific weight option chosen for a geotextile depends on the project requirements, such as the soil conditions, desired strength, and intended application.

- Q: What are the environmental considerations of geotextiles?

- Geotextiles have several environmental considerations, including their potential to release microplastics into the environment, their impact on soil and water quality, and their potential for improper disposal. Additionally, the production and manufacturing processes of geotextiles may contribute to carbon emissions and energy consumption, further affecting the environment. Therefore, proper usage, disposal, and monitoring of geotextiles are essential to minimize their environmental impact.

Send your message to us

Géotextile Brico Depot Needle Punched Nonwoven Geotextiles for River Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords