NDT 2.25MHz Small Phased Array Sensor for Non Destructive Testing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Carbon Steel Weld Probe:

Specific

Features & Applications

1.High compatibility, can be compatible with most phased array flaw detectors.

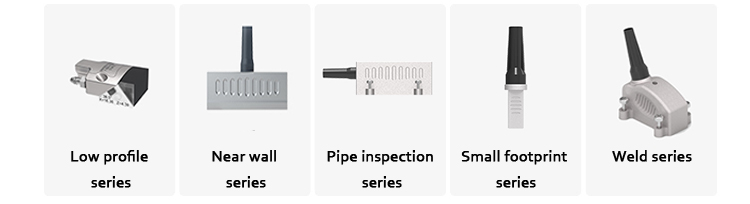

2.carbon steel weld series:

3.Thick weld inspection from 3 mm to 60 mm4.Manual or automatic detection

5.Wide thickness measurement

6.Excellent signal to noise ratio

7.Moderate constitution and large monitoring range

8.Thick plate material and weld

9.Forgings, noise or granular materials

10.Moderate constitution and large monitoring range

Specification

*The standard cable length is 2.5m/8.2ft. The phased probe can be customized,include frequency, element number and pitch,etc.

Probe Naming Rules

*The standard cable length is 2.5m/8.2ft. The phased array probe can be customized, include frequency, elements number and pitch, etc. If you have any customing requirements, our experts will work directly with you to design and manufacture customized probe, wedge, scanner.. ...

Advantages

Superior Product Performance

Test report is supplied with every probe.This form contains following contents:

High compatibility

We provide probes with different connectors according to your requirement. More connector types are available, please contact us if the connnector type is not listed below.

D19(Phasor Connector) D3(Omniscan Connector) D5(Connec 78PIN)

D6(Hypertronics 160 PIN) D7(Topaz/Zircon) D8(ITT CANNON 96PIN)

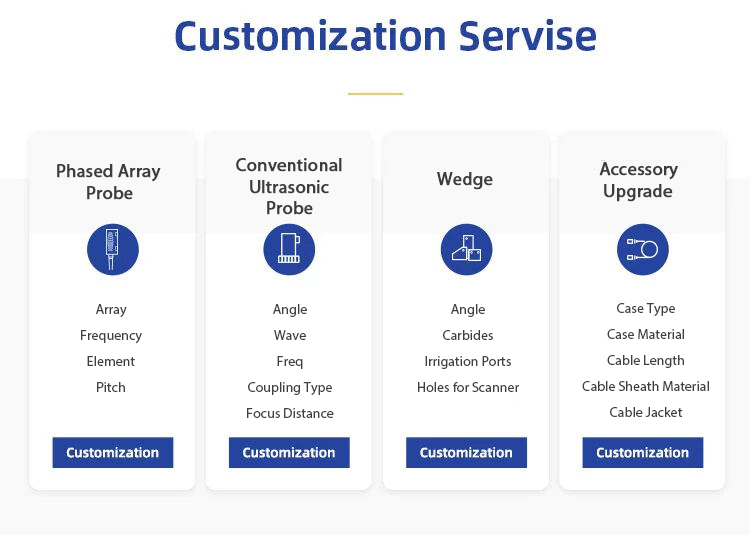

Customization Service

Customization Service

Package

M2probe provide each product with a safety box.It is external anti-fall and impact resistant. Pre-cut mesh cotton make it fully protect product safety during transportation.

Recommend Products

Phased Array Probe

Our Factory

\

Certifications

FAQ

1.Q: Can you customize the probes, wedges, scanners according to our requirement?

A: Yes, we support all customizing requirements to meet your needs. OEM/ODM are welcomed.

2.Q: Are you factory direct supply? Can we have a visit to your factory?

A: Yes, we are factory direct supply. Our factory locates at Shanghai city, welcome to visit our factory!

3.Q: Does your factory have ISO certification?

A: Yes, our factory has ISO9001:2005 certification, we strictly follow ISO stantdards throughout whole processes from R&D to manufacturing.

4.Q: What's the MOQ? Can we buy sample to test?

A: At least 1 piece of product. Welcome to order sample.

5.Q: Can M2PROBE manufacture wedges with non-standard angles for steel and other materials?

A: Yes. The customer must specify the refracted angle desired, test material velocity, and any other important factors that may play a role in the success of the inspection. Note that, in some cases, the performance will be quoted only on a "best effort" basis. A premium will apply and/or sometimes a minimum required order quantity.

6.Q: What is the price of the product?

A: We will provide the best quality machines with best price. Never compromise performance for price.

7.Q: How long is the lead time for the product?

A: The delivery time for standard probe is usually 20 days, and for customized products, it depends on your demands of probe andtechnical difficulty.

- Q: Before anyone blindly answers this, I'd like to first request that only people in the power transmission industry answer, as they are the only ones likely to know.I have a customer who is asking to mount several very large pieces of electrical equipment 15 feet in the air, mounted to a large structure. All of these equipment pieces are 5000 or more pounds and pad-mount by design. I am questioning this request on the basis of legality. Basically, I am curious to know, is there anything in the NEC that says mounting pad-mount equipment overhead is illegal? If so, I could really use a hint as to what section of the NEC code.

- I don't believe that there is anything in the NEC that addresses this. Obviously, installing anything on a structure presents challenges that require the attention of a qualified structural engineer. And depending on the location, you could be facing some additional concerns. You would need to check on seismic activity in the area, and since 'pad mount' equipment has a broad profile, wind-loading could be more challenging if you have a wind-force specification to meet. The other issue you would need to consider is whether installation on a structure presents any particular safety concerns. Without knowing any more, my inclination would be to think that you might want to provide an enclosure around the structure to prevent civilians (rmeaning 'teenagers and drunk college students) from climbing it. Just out of curiosity - why does your client want this? We know that the client is always right - even when he insists to stupid things. I trust there is a good reason for asking for something that is bound to increase installation cost by probably 100%.

- Q: Hey, I need to find out different electrical equipment used in a Beauty Salon and I can hardly think of anything! I can only think of wax pots and tanning beds :S Any other suggestions? Actual answers only please, don't bother writing Do your own homework or whatever because I really can't be bothered with people like that. Like I said I have TRYED and I cannot think of alot. Thankyou :)

- Those blow dryers you sit under, and also those little dryers used to dry your nails when you get them done.

- Q: A -INDIVIDUAL GROUNDS B -THROUGH AN ISOLATION TRANSFORMER C- ONE COMMON GROUND D- NO MORE THAN 3 GROUNDS E- IN PARALLEL?

- The national electric code states where no ground is available, you have to replace a two prong receptacle with another two prong receptacle. An exception is made for installing a GFI receptacle (3 prong) in the place of the 2 prong. Be aware, there still won't be a ground available for your equipment. Those are the only legal options you have besides rewiring to provide a ground. That is assuming there is no ground available at the box and chances are there is not. You are not allowed to run a ground wire separately to a water pipe or ground rod as the non trained hacks are going to try to tell you. That is a code violation. All conductors for a circuit must be run together according to the National Code. To convert your house or maybe just certain rooms, call a real electrician or pull new wires to the receptacles.

- Q: I received 63J at meps and it is a chemical equipment repair job can someone give me the details on this job and what i would do if mobilized. thank you.

- Quartermaster and Chemical Equipment Repairer (63J) The Quartermaster and Chemical Equipment Repairer performs unit and direct/general support maintenance on tactical utility, precise power generation, laundry and bath equipment, pumps, engines, burners, filter units, smoke generation and water purification or associated items. The Quartermaster and Chemical Equipment Repairer is primarily responsible for supervising or performing maintenance on chemical equipment, quartermaster machinery, forced air-heaters and special purpose equipment. Some of your duties as a Quartermaster and Chemical Equipment Repairer may include: Maintaining and repairing electrical/fuel heater systems, pumps, decontamination systems, protective filter systems, smoke generator systems and quartermaster and chemical equipment electrical systems Job training for a Quartermaster and Chemical Equipment Repairer consists of nine weeks of Basic Training, where you'll learn basic Soldiering skills, and 11 weeks of Advanced Individual Training, including practice in marine engine maintenance and repair. Part of this time is spent in the classroom and part in the field. You'll learn: Internal combustion engine theory Use and care of hand and power tools Helpful attributes include: An interest in shop mechanics An interest in fixing engines and machinery An ability to use hand and power tools A preference for doing physical work Advanced level Quartermaster and Chemical Equipment Repairers supervise and train other Soldiers within the same discipline. The skills you learn as a Quartermaster and Chemical Equipment Repairer will help prepare you for a civilian career with the marine transportation, commercial fishing, oil exploration or oil drilling industries. You'll be able to consider a future as a marine engine mechanic.

- Q: I want to get into a field that involves fixing electrical equipment. I have always loved taking apart things like my Xbox/Playstation/cell phone so I could fixing them when they broke and I would like to further this into a career. What type of field should I study in order to pursue this goal? I am a student at the University of Arizona, so if you know of any programs there that would help a lot.

- None, depending on how or where you work. If you work for yourself you don't need any degree at all. You need to be an electronics service engineer. You have to be able to do the job. That's more important than having a piece of paper that says you got good grades and showed up or class. (I would argue this is true for most fields) You can get a degree in electronics engineering at many schools. It would be very helpful to find work at a company specializing in service of these things. Nobody repairs cell phones, it just isn't worth doing.

- Q: If I decide to choose electrical engineering as my college major what would I be doing on a regular basis for my job?

- Electrical engineers specialize in research and development of electrical equipment, systems, parts and products. To become an electrical engineer, you typically complete a four-year electrical engineering program or get an engineering degree with electrical specialization. Electrical engineers work in offices, lab facilities or at manufacturing plants, and often have a hand in developing new products and uses of technology.

- Q: Hi I'm doing a music project at the moment, writing songs, music, etc.my genre would probably be considered alternative/electronic rockMy current vision for my set up is an electric guitar and my macbook.I create most of the music via macbook (drum parts, synth parts, basically all the programing)Playing live i suppose i'd play these songs on my laptop. While i do this, i sing, and play rhythm guitar along with the samples and instrumentals on the macbook.My question is, how do I connect all this stuff on stage? Could anyone out there recommend anything that I could use to connect my macbook to speakers for performing live.p.s I know nothing of playing with electrical equipment (been doing acoustic for a very long time) all I know about live equipment is connecting a guitar to a guitar amp.so is there like a way to connect a macbook to an amp? or speaker of some sort?Thanks in advance.

- In order to get the most from your Mac as sound generator use a reasonably good audio interface (like the E-mu 0404 usb or something from M-audio). This should be connected to a mixer and this one to the PA system. You also should connect your microphone and guitars to the mixer too, so you can control the volume of each instrument, including the Mac. Although you can connect the mac directly to an Amp I won't do that in order to get control of volume and have better sound. Computers generally don't like live performing. Electric voltage can be unstable (heavy power consumption and lights on-off pattern). Use the appropriate electric equipment to make sure the computer always receive the correct amount of voltage. If not, it can fail and ruin your performance. Make a test where possible.

- Q: I have heard from a lot of people about the greatness of an EE degree but never got the chance to ask why? So what is so cool about an electrical engineering degree that makes it better than the other engineering degrees out there?

- I've got a Electrical Engineering Diploma. I work in the electrical field. I'd be a Graphic Designer.

- Q: Are you taught job skills required to work for a company? or are you trained to specifically do a job like they trust your knowledge and teach you specifics?

- Simply put: You are expected to know all the ways the job can be done. They will tell you which way they want it done.

- Q: Can I use 240 volt electrical equipments into 220 volt? Should I need a transformer?

- No, you don't need a step down transformer. It's the same with the standard 115 volt wall outlet. if you use a voltmeter to read a standard wall outlet, very rarely will it be precisely 115 volt. Normally you get readings of between 110 volt to 120 volt. In North America we use 2 phase 240 volt (splits to form 2x 120 volt @ 60Hz) In most of Europe use 1 phase 240 @ 50 Hz. So if you're planning to use a European piece of equipment (single phase, 240 volt, 50 Hz) on North American (two phase, 240 volt, 60 Hz[x2]), don't because you'll risk damaging your equipment.

Send your message to us

NDT 2.25MHz Small Phased Array Sensor for Non Destructive Testing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches