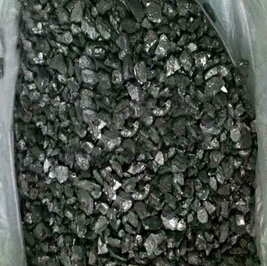

Natural graphite graphite paint/carbon raiser recarburizer

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Carbon Raiser:

Carbon raiser:

- F.C is 90-95% min

- 6-10mm,sulfur0.2% min

- Be made of Ningxia anthracite

- High absorptivity

Quick Details:

Place of Origin: Dalian China (Mainland) | Brand Name: ShengSa | Model Number: SSGCA |

Application: Foundry;Metallurgy | Dimensions: High-carbon | Chemical Composition: C ; S ; V ; ASH |

C Content (%): 93%min | S Content (%): 0.3%max | Ash Content (%): 6%max |

Vol . Matter: 1.5%max | Moisture content: 0.8%max | Size: as per customer's requirement |

Color: Black |

Packaging & Delivery:

Packaging Detail: | a.1 mt super bags. b.1 mt super bags on pallets. c.25kgs small bags on 1 mt super bags. d.25kgs small bags on 1 mt super bags on pallets. e.as per customers' requirement. |

Delivery Detail: | within 25 days against the down payment |

Gas Calcined Anthracite/GCA

Fixed carbon | 95%min |

Ash content | 4%max |

Vol . Matter | 1.2%max |

Sulphur content | 0.25%max |

Moisture content | 0.5%max |

Size | As per customers' requirement |

packing | 25kg paper bag on the pallet or 10kg paper bag shrieked wrapped on the pallet or 1MT big bag or other packing as required |

delivery time | 20days or depends on the order quantity |

Supply ability | 8000 Metric Ton/Metric Tons / Month |

Payment terms | L/C at sight or T/T |

Size: 1-4mm, 1-5mm, 3-8mm, 8-20mm (as per customers’ requirement)

Usage: Gas Calcined Anthracite/GCA is carbon raiser, widely used in steel-making, metallurgical

- Q: What are the impacts of carbon emissions on the spread of infectious diseases?

- Carbon emissions have a significant impact on the spread of infectious diseases. The burning of fossil fuels, such as coal, oil, and natural gas, releases large amounts of carbon dioxide (CO2) and other greenhouse gases into the atmosphere. These emissions contribute to climate change, which in turn affects the distribution and transmission of various infectious diseases. One of the main ways carbon emissions influence the spread of infectious diseases is through changes in temperature. Rising global temperatures create favorable conditions for the survival and proliferation of disease-causing agents and their vectors. For example, warmer temperatures can expand the geographic range of disease-carrying insects like mosquitoes, which are responsible for transmitting diseases such as malaria, dengue fever, and Zika virus. Additionally, climate change caused by carbon emissions can disrupt ecosystems and alter the behavior of animals that serve as hosts or reservoirs for infectious diseases. Changes in migration patterns, breeding cycles, and hibernation can affect the dynamics of diseases, making them more difficult to control. For instance, warmer temperatures may lead to the expansion of tick populations, increasing the risk of tick-borne diseases like Lyme disease. Furthermore, carbon emissions contribute to air pollution, which has adverse effects on respiratory health. Pollutants like particulate matter and nitrogen dioxide can weaken the immune system and make individuals more susceptible to respiratory infections, including influenza and pneumonia. These pollutants also exacerbate the severity of respiratory symptoms in individuals already infected with respiratory diseases. The impacts of carbon emissions on the spread of infectious diseases are not limited to direct effects on humans. Changes in climate patterns can disrupt agricultural systems, leading to food insecurity and malnutrition. These conditions weaken the immune systems of vulnerable populations, making them more susceptible to infectious diseases. It is important to recognize the connection between carbon emissions and the spread of infectious diseases in order to mitigate their impacts. Reducing carbon emissions through transitioning to cleaner energy sources and implementing sustainable practices can help mitigate climate change and limit the expansion of disease vectors. Additionally, investing in public health infrastructure and surveillance systems can enhance our ability to detect and respond to outbreaks, minimizing their spread and impact on human populations.

- Q: How does carbon cycle through the environment?

- The carbon cycle is the process by which carbon moves between the atmosphere, land, oceans, and living organisms in a continuous cycle. It is crucial for maintaining a stable climate and supporting life on Earth. The cycle begins with carbon dioxide (CO2) in the atmosphere, which is absorbed by plants during photosynthesis. Through this process, plants convert CO2 into organic carbon compounds, such as sugars and carbohydrates, which they use for growth and energy. This carbon is then passed along the food chain as animals consume plants or other animals. When plants and animals die or excrete waste, their organic matter decomposes, releasing carbon back into the environment. This decomposition process is carried out by microorganisms, such as bacteria and fungi, which break down the organic matter and release carbon dioxide as a byproduct. Some carbon may be stored in the soil for long periods, depending on factors like temperature and moisture. This stored carbon in the soil can be released back into the atmosphere through processes like microbial respiration or erosion. Another way carbon returns to the atmosphere is through the burning of fossil fuels such as coal, oil, and natural gas. When these fuels are burned for energy, they release carbon dioxide into the atmosphere, contributing to the greenhouse effect and climate change. The oceans also play a crucial role in the carbon cycle. They absorb a significant amount of carbon dioxide from the atmosphere through a process called carbon sequestration. Marine plants, such as phytoplankton, also photosynthesize and store carbon in their tissues. When these organisms die, they sink to the ocean floor, where the carbon can be stored for long periods in the form of sediment or dissolved in the water. Oceanic circulation and biological processes also redistribute carbon throughout the oceans, with surface water exchanging carbon with the atmosphere. Additionally, the oceans act as a carbon sink, as they can store vast amounts of carbon dioxide, helping to regulate its levels in the atmosphere. Overall, the carbon cycle is a complex and interconnected process that involves various natural and human activities. Understanding and managing this cycle is crucial for mitigating climate change and maintaining the health of our environment.

- Q: What are the consequences of increased carbon emissions on human health?

- Increased carbon emissions have numerous consequences on human health. Firstly, carbon emissions contribute to the formation of air pollution, specifically fine particulate matter (PM2.5) and ground-level ozone, which can lead to respiratory issues such as asthma, bronchitis, and other respiratory diseases. Additionally, exposure to air pollution from carbon emissions has been linked to an increased risk of cardiovascular diseases, including heart attacks and strokes. Moreover, carbon emissions contribute to climate change, resulting in more frequent and intense heatwaves, extreme weather events, and the spread of infectious diseases. These phenomena can have direct and indirect impacts on human health, leading to heat-related illnesses, injuries, mental health issues, and the displacement of communities. Overall, the consequences of increased carbon emissions on human health are significant and require urgent action to mitigate their effects.

- Q: What is carbon neutral manufacturing?

- Carbon neutral manufacturing refers to the practice of minimizing and offsetting greenhouse gas emissions produced during the manufacturing process. It involves implementing sustainable measures, using renewable energy sources, and investing in carbon offset projects to balance out the emissions released. This approach aims to achieve a net-zero carbon footprint, where the amount of carbon dioxide emitted is equal to the amount removed from the atmosphere, thus mitigating climate change impacts associated with manufacturing activities.

- Q: How does deforestation contribute to carbon emissions?

- The role of deforestation in contributing to carbon emissions is significant. When forests are cleared or burned, the carbon stored in trees and vegetation is released into the atmosphere as carbon dioxide (CO2), a greenhouse gas that contributes to global warming. Forests act as natural carbon sinks, absorbing CO2 from the atmosphere through photosynthesis. Trees and plants convert CO2 into oxygen and store the carbon in their trunks, branches, leaves, and roots. This process helps regulate the Earth's climate by reducing the concentration of CO2 in the atmosphere. However, deforestation disrupts this natural carbon storage system. The carbon once stored in trees and vegetation is released back into the atmosphere, increasing the concentration of CO2. Burning forests exacerbates this process, releasing even larger amounts of carbon through the combustion of trees and plant material. The loss of forests also leads to a decrease in biodiversity and the destruction of habitats for numerous species, which disrupts the delicate balance of ecosystems. As a result, these ecosystems become less efficient at absorbing and storing carbon, further contributing to increased carbon emissions. Moreover, deforestation indirectly contributes to carbon emissions through various means. For example, when trees are cleared, the exposed soil is exposed to sunlight and heat, causing it to dry and release stored carbon. Additionally, deforestation often leads to the conversion of land for agricultural purposes, such as livestock farming or palm oil plantations, which can increase methane emissions, another potent greenhouse gas. To summarize, deforestation contributes to carbon emissions by releasing stored carbon, disrupting the natural carbon storage system, and indirectly contributing to the release of other greenhouse gases. It is crucial to address deforestation and promote sustainable land management practices to mitigate the effects of climate change and reduce carbon emissions.

- Q: How does carbon affect the formation of ground-level ozone?

- Carbon does not directly affect the formation of ground-level ozone. Ground-level ozone is primarily formed through a complex chemical reaction involving oxides of nitrogen (NOx), volatile organic compounds (VOCs), sunlight, and heat. However, carbon-based compounds, such as hydrocarbons, can indirectly impact the formation of ground-level ozone. When carbon-based compounds, like hydrocarbons, are emitted into the atmosphere from sources such as vehicles, industrial processes, and fossil fuel combustion, they can react with nitrogen oxides in the presence of sunlight to form ozone. This reaction occurs in the presence of volatile organic compounds (VOCs) and nitrogen oxides (NOx), which are the primary precursors of ground-level ozone. Elevated levels of carbon-based compounds, particularly in the presence of NOx and sunlight, can enhance the formation of ground-level ozone. This is because the carbon-based compounds act as catalysts, accelerating the chemical reactions that lead to ozone formation. Additionally, the combustion of carbon-based fuels, such as gasoline and diesel, releases nitrogen oxides into the atmosphere, which can further contribute to the formation of ground-level ozone. It is important to note that carbon-based compounds alone do not directly cause ground-level ozone pollution. Rather, they contribute to the formation of ground-level ozone when combined with other pollutants, such as nitrogen oxides and sunlight. To mitigate the formation of ground-level ozone, it is necessary to reduce emissions of carbon-based compounds, as well as other ozone precursors like nitrogen oxides and volatile organic compounds.

- Q: What is carbon capture and storage?

- Carbon capture and storage (CCS) is a process that involves capturing carbon dioxide emissions from industrial sources, such as power plants, and storing them underground or using them for various purposes. It aims to mitigate the release of greenhouse gases into the atmosphere, helping to combat climate change by reducing carbon dioxide levels.

- Q: What are the impacts of carbon emissions on the stability of kelp forests?

- Carbon emissions have significant impacts on the stability of kelp forests. Increased carbon dioxide levels in the atmosphere lead to ocean acidification, which negatively affects the growth and survival of kelp. Acidic conditions hinder the ability of kelp to absorb essential nutrients, weaken their structure, and make them more susceptible to damage from storms and other disturbances. Additionally, rising ocean temperatures associated with carbon emissions can lead to the expansion of harmful algal blooms that compete with kelp for light and nutrients. These combined effects pose a threat to the stability and biodiversity of kelp forests, with potential cascading impacts on the marine ecosystem.

- Q: How is carbon used in the production of cosmetics?

- Cosmetics utilize carbon in diverse ways during their production. A prevalent application of carbon in cosmetics involves its use as a coloring agent. Carbon black, a specific form of carbon, imparts a deep black hue to numerous cosmetic products such as eyeliners, mascaras, and eyeshadows. Nail polishes and lipsticks also incorporate carbon as a colorant. Furthermore, carbon finds application in the creation of activated charcoal, which has gained popularity due to its detoxifying properties. Derived from carbon, activated charcoal features prominently in skincare products like face masks, cleansers, and scrubs. Its ability to absorb excess oil and impurities from the skin makes it a favored ingredient for products targeting oily and acne-prone skin. Moreover, carbon contributes to the manufacturing of exfoliating products. Tiny particles known as microbeads, utilized in facial scrubs and body washes to eliminate dead skin cells, can be crafted from carbon. These microbeads gently exfoliate the skin, leaving it rejuvenated and smooth. Additionally, carbon plays a role in the production of certain cosmetic base materials. Emollients, crucial substances that moisturize and soften the skin, rely on carbon as an essential component. Creams, lotions, and lip balms commonly contain emollients, which enhance their hydrating properties. To summarize, carbon assumes a vital role in cosmetic production. Its versatility as an ingredient contributes to the aesthetics and functionality of various cosmetic formulations, ranging from providing color to enhancing the efficacy of skincare products.

- Q: Wrought iron, steel, cast iron, cast iron, according to the content of the carbon? How many?

- Iron is almost a smelting furnace and cast iron products. Two smelting products, generally with silicon, manganese and other elements in pig iron based, often also need to be nurtured, spheroidization, compacted and heat treatment process.

Send your message to us

Natural graphite graphite paint/carbon raiser recarburizer

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords