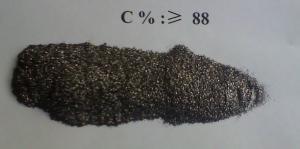

Natural Flake Graphite Powder High Purity

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Quick Details

Place of Origin:China

Application: Refractory

Shape: Powder

Material: F.C ;ASH; MOITURE

Chemical Composition: F.C ASH

Product name: Natural Flake Graphite

Payments terms: 1. 100% L/C at sight 2. 30% T/T prepayment, balance against BL copy

Delivery Time: Within 30 days after receiving L/C or 30% T/T prepayment

Advantage: Timely Shipment, High quality, Good performance

Packing: 25kg/bag, 1mt/bag or as customers' requirements

Size: powder

Sample supply: free sample

Color: BLACK

MOQ: 20Mt

Supply Ability

Supply Ability:300 Metric Ton/Metric Tons per Month

Packaging & Delivery

Packaging Details1MT/bag or as customers' requirements.

Application of natural flake graphite powder:

1. Graphite with excellent electrical conductivity, thermal conductivity: Graphite’s conductivity is higher than the general non-metallic minerals a hundred times. Graphite’s thermal conductivity is much better than steel, iron, lead, and other metal element materials. With the great properties, graphite powder is widely used as electrode, the positive brushes, carbon rod, carbon tubes, mercury positive converter, graphite gaskets, phone parts, television picture tube coatings in the electrical industry as a manufacturer.

2. natural flake graphite powder is also a good lubricating additive powder. The performance of lubrication depends on the size of the graphite flake graphite, the larger of the flake the smaller of the coefficient of friction and lead to the better lubrication.

3. natural flake graphite powder is stable powder at room temperature, graphite is acid, alkali and corrosion resistance and also resistance of organic solvents.

- Q: Why can aluminium hydroxide not be used to make refractory material?

- Hope my answer is helpful to you. It decomposes and produces aluminium oxide and water after heating, chemical equation for the reaction is: 2Al(OH)3=△=Al2O3+3H2O. Aluminium hydroxide can't be directly used to make refractory material because aluminium hydroxide is not stable.

- Q: What requirements should refractory materials meet?

- The operating temperature of forging furnace is above 1000, which can ensure the normal operation of the furnace, prolong the life of the furnace and save energy. General requirements for refractories are as follows. 1 They should deform at a sufficient temperature without melting. 2, They should have necessary structural strength without softening and deforming. The volume should be stable at high temperature without expansion, contraction or cracking. 4, They can resist erosion of molten metal, slag, gas and other chemicals.

- Q: What's the refractory material in common use currently?

- (1) Alumina-silica refractory brick: Except the transition band, hot end and firing zone of the rotatory cement kiln, it can be applied to the whole burning system of the precalcining kiln, such as the fixed wall lining, wicket, cooling machine, tertiary air duct, burner, etc. It mainly includes alkali-resisting brick, high alumina (anti stripping) brick, silica-mullite brick, etc. (2) Basic refractory: For the upper transition band close to the part of burning zone and the burning zone, its inner lining can endure the highest flame temperature of 2000℃ and material temperature of 1350℃-1400℃, and it also has to withstand the permeation of sulfur and alkali compounds, permeation, thermal shock and oxidoreduction of hot-melt clinkers (liquid phase), mechanical stress of elliptic cylinder deformation, etc. Therefore, inner linings are the most demanding parts to withstand stress, and only basic refractory can meet with requirements under this working condition. (3) Fireclay insulating refractory: Its microstructure has notable characteristics of high porosity, large pore size and thermal insulation performance. For its low volume density and light weight, it is usually referred to as lightweight refractory. Fireclay insulating refractory product has great varieties, and it is usually classified and named according to its chemical and mineral compositions or production raw materials, and it is also classified according to its operating temperature and material form. Currently, the most used main thermal insulation material for the precalciner kiln system at home and abroad is calcium silicate board; besides, light weight castable and insulating fire brick are increasingly used year by year. Other thermal insulation materials are mainly ceramic fiber products.

- Q: What is the magnesium carbon refractory?

- The composition of refractory brick raw material There are many types of refractory brick raw materials, mainly divided into six categories: Soil, stone, sand, mineral, power and others. One of the original material, soil: Aluminum, kaolin, clay, diatomaceous earth The second raw material, Stone: fluorite, kyanite, andalusite, forsterite, vermiculite, mullite, pyrophyllite, chlorite, dolomite, sillimanite, magnesia-alumina spinel, silica The third kind of raw material, sand: Pottery, zircon sand, quartz sand, magnesite The fourth kind of raw material, ore: Chrome ore The fifth kind of raw material, powder: Aluminum powder, silica powder, silicon powder The sixth kind of raw material of refractory brick, others: Asphalt, graphite, phenolic resins, perlite, cenosphere, sialon, corundum, silicon sulfate, silicon carbide, sodium silicate, silica solution, boron carbide, calcium aluminate cement, nitride material, shale ceramisite, alumina, alumina sol and zirconia, etc.

- Q: What are the classifications of refractory? Which category does steel ladle castable belong to?

- In addition, it can be divided into refractory, shapeless refractory material. And it can also be divided into acidic refractory, basic refractory and neutral refractory. If you want to know more, you can ask thme. In fact, every company has different refractory clasifications. There are more clasifications in Huaheng.

- Q: What parts of cement kilns are refractories used on?

- Generally they are used in cyclone, feed pipe, and duct and refractories are high-strength alkali-resistant castable, calcium silicate board, high-strength alkali-resistant brick, dome-shaped alkali resistant brick. Refractories in smoke chamber are high-alumina refractory castable, anti-skinning pouring material and calcium silicate board. Refractories in duct are high-strength alkali-resistant bricks, calcium silicate boards and steel fiber reinforced castable. Refractories in hooding parts of kiln are high strength castable high alumina and calcium silicate board. Refractories in rotary kiln are phosphate bonded high alumina brick, silmo brick, magnesia chrome brick, steel fiber reinforced castable. Refractories in grate?cooler are vault alkali brick, high alumina refractory castable, steel fiber reinforced castable and calcium silicate board. Refractory in coal burner is dedicated castable for coal burner.

- Q: Where do China and foreign countries do more refractory materials?

- The domestic production of refractory materials base in Henan Xinmi, Xinmi has a lot of production of refractory material factory, Zhengzhou gold refractories plant is relatively large, there is a need to go to visit the factory.

- Q: How many types of fire-resistant material?

- 1. Acid fire-resistant material refers to one with more than 93% SiO2. It is featured by resistance to the corrosion of acidic slag ad high temperature and easy to react with alkaline molten slag. 2. Alkaline refractory material generally refers to one with magnesium oxide or magnesium oxide and calcium oxide as the main component. It has high refractoriness and strong resistance to basic slag. 3. Silicate aluminum refractory material refers to one with SiO2, Al2O3 as the main component. According to the content of Al2O, it can be divided into three categories: half siliceous (15-30% Al2O3), clay (Al2O3 30 ~ 48%), high aluminum (more than 48% of Al2O3). 4. Fused cast refractory material refers to shaped refractory products made by high temperature melting and casting.

- Q: Where is the development of refractory industry?

- Refractories for continuous casting is an important part of the continuous casting machine, in addition to the characteristics of general refractory material, also for the purification of molten steel and improve the steel quality, stable molten steel temperature and composition, control and regulate the flow of the molten steel and other functions, so it is called functional refractories.

Send your message to us

Natural Flake Graphite Powder High Purity

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords