Multi-Material Injection Moulding Machines

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Description of Multi-Material Injection Molding Machines

Introduction

1.Reliable plastic injection machine with servo motor ,equipped with servo motor , closed loop control for pressure and flow .low noise, high precision and energy saving .

We design, manufacture and supply our own brand of injection molding machine called with clamping force ranged.

2. Inject all kinds of plastic parts, bottle perform, engineering plastic, UPVC, PVC, PE pipes fitting, components’ for automotive, household, electronics, telecommunication, ETC

Product Traits

1. Equipped rotary platen with different specification on the standard machine according to customer's needs.

2. Simplify mold design enabling reduction in production cost and lead time.

3. The platen can be rotated 180 degree to and fro when it installed on co-injection machine with turning on hydraulic power and control circuit.

4. Two units of water channels with water outlet installed on the platen surface.

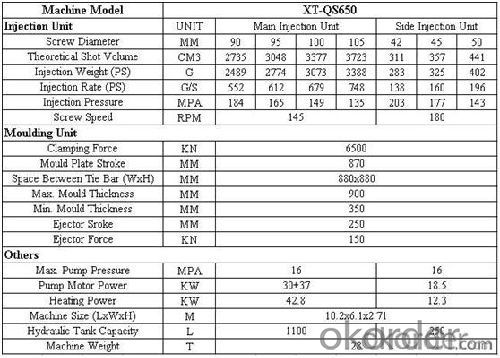

Specification of All-Electric High Precision Injection Molding Machines

Package of All-Electric High Precision Injection Molding Machines

Wooden box packed, suitable for train or sea worthy delivery.

FAQ

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: What kind of equipment does the plastic bottle crush processing plant need?

- Would you like to crush the plastic bottle? That crusher, crushing, but also processing it? Besides, I have friends who sell machines. If you need this kind of equipment, I hope I can help you.

- Q: How should be the material after refining to smooth feeding, shredders or other equipment?.

- After refining can also screw? Open mill, mixer, used as rubber industry pro. The material on the twin screw extruder must be powder and pellets.

- Q: The processing of plastic bottles

- Plastic bottle molding is the process of making final plastics from polymers made from synthetic resin manufacturing plants. The processing method (usually called plastic processing) (including compression molding), extrusion (extrusion) and injection molding (injection molding), blow molding (blow molding), rolling, to go through a total pressure plastic, extrusion, injection molding, blow molding, foam molding, calendering, etc. six processes.1 、 pressing and moldingPress molding is also known as molding or pressing, and molding is mainly used for molding thermosetting resins such as phenolic resin, urea formaldehyde resin and unsaturated polyester resin.2. ExtrusionExtrusion, also known as extrusion molding, is the use of extruders (extruders) to heat the resin continuously through the mold extrusion of the desired shape of the product. Extrusion is sometimes also used in the forming of thermosetting plastics and can be used in the moulding of foamed plastics. The advantage of extrusion is that it can extrude various shapes of products. The production efficiency is high, it can be automated and continuous production. The disadvantage is that thermosetting plastics can not be widely used in this process, and the size of products is prone to deviation.3, injection moldingInjection molding is also called injection molding. Injection molding is the use of injection molding machines (or injection machines) to inject thermoplastic melts at high pressure into the mold and to cool and cure the products. Injection molding can also be used for moulding thermosetting plastics and foams. Injection molding has the advantages of fast production, high efficiency, automatic operation, and complicated shape. It is especially suitable for mass production. The disadvantage is that the equipment and mold cost is high, the injection molding machine cleaning more difficult.

- Q: What are the features of plastic injection gears and machined plastic gears?

- Injection of better, smooth finish, smoothness can be done on the mold, the strength is also good. When machining, some of the transmission, the edge may be very difficult to process, very beautiful

- Q: from raw material to particle forming, need several devices, what are they? _?

- I also want to open such a factory, does the profit? I'm using scrap plastic as a particle here, so I want to check it out.

- Q: Do waste plastics recycling processing, the state subsidies, and now the prospects are good?

- Plastic machinery production of this piece, I personally think that Shandong is still a lot of production enterprises. All regions have done, and quite a lot, forming a production chain of processing. Shandong outstanding people, saints land, people are very real. Suggest that you go to Shandong site visits, compared to, not light, cheap, the most important thing is to look at the quality of the machine, after-sales service. Just like my friend bought a machine, the price is not very cheap, but the quality of the machine is good, and there is nothing wrong with it.

- Q: Every time I look for work on the Internet, I am confused. What kind of industry does the plastic belong to?..

- Plastic processing industry, China Standard Classification Number: Y28, ICS, classification number: 83.140.

- Q: One hundredUrgently!!!Find a kind of plastic that can be used for machining. The better the machining performance, the cheaper the better.Used for the principle model, in the past, when the school practice, used a milky white opaque material, feel good, but I do not know what the name.Copy paste party, do not come to a great God level, experienced best. Kneel thanks!Can PVC be used for machining? As long as you can get on the lathe. If there is a better buy channels.To pipe, diameter 20,40, 65mm 1 each. The lengths are 450450335mm.Can PMMA (acrylic) stick be machined? The supervisor told me that nylon rods do not work and that moisture size is not guaranteed.Then suggest I use this... Which is better than PVC? Thank you

- Nylon low pressure polypropylene performance is best,.PVC if you want to be used to process, you can choose the wall thickness of the pipe, the knife when the speed as low as possible, because the temperature is high, easy to paste,You can go to the building materials market to see, if there is PVC, choose PVC, no, choose PP-R water supply pipeline can also

- Q: What kind of units do you need to process plastic injection products?I own the business, there are plastic injection molding machine more than, can produce all kinds of plastic products, order ~ unit in Hangzhou ~!

- has a great competitive advantage in the city of Ji'nan, 5 sets of CNC machining center, CNC lathe 2 units, the company is Chinese FAW heavy truck, China, supporting services Joyoung electric lights, Lent, Qingdao's foreign trade and other well-known enterprises, and repeatedly won the title of excellent supplier,

- Q: What equipment? How much money do not.. at first. There are several sets of injection molding machine can be about 2... Mainly plastic injection molding. The ABS PA PE PP PVC... Etc. in this area. Please know that a friend told Kazakhstan. Thank you.

- 3. cooling tower or water cooler {if cooling pool is small, buy}The production material crushing and recycling of the 4. mill {}5. mould temperature machine {product on mold temperature requirements higher, buy}6. oven {dry on the material, it is recommended to buy directly installed on the machine, drying faster, floor type, because there are several kinds of materials, while drying, the temperature is not good control.7. blender {material color or when adding material}8., the mold should be loaded big gourd, small mold can buy a lifting trolley, a set of mold tools.

Send your message to us

Multi-Material Injection Moulding Machines

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords