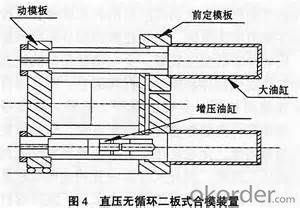

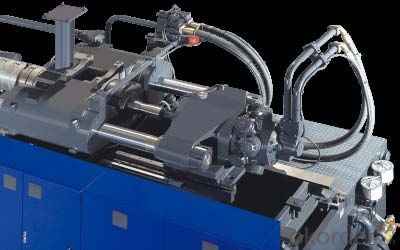

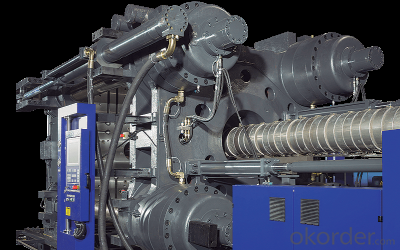

Large two-platen (Direct Hydraulic Clamping) Injection Moulding Machines

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 SET unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Description of PLASTIC INJECTION MOLDING MACHINE-C SERIES

128J full hydraulic two-platen injection molding machine is special designed for plastic injection moulding.

Full hydraulic two-platen injection molding machine for plastic, relying on independent intellectual property rights, make full use of the internal groups advanced technology HOYEAelectrohydraulic control,HOPEA(microcomputer frequency Conversion control) and precision injection molding machine developed independently by injection molding machine experienced engineers in our Machinery. With the latest European Hydraulic Design Concept, Machinery electro-hydraulic control specialists make great efforts to build the plastic injection equipment with environment-friendly and energy-saving.

Advantage of PLASTIC INJECTION MOLDING MACHINE-C SERIES

Super-Large space, we can make machine as the requirement of customers products, with parameters strong adaptability.

Short clamping stroke line, is only the distance between main moving platen and fixed platen, mould- clamping is high rigidity and precision.

Main moving platen adopts oil-less self-lubricating copper sets guide, ensure clean production environment. Support sliding feet can choose linear slide way guide, which greatly enhance the rigidity of clamping unit and service life of mould..

Using the latest German sealing technologies and products, ensure the sealing performance high.

Hydraulic system adopts proportional integrated instrument control system to ensure the mould transfer rapidly, stably.

Electrical system uses Siemens controller, with high speed, good stability, high performance and good scalability.

Specification of PLASTIC INJECTION MOLDING MACHINE-C SERIES

Item | Unit | Parameter | ||

Screw no | A | B | C | |

Screw Dia | mm | 38 | 42 | 45 |

Screw LD ratio | 23.2 | 21 | 19.6 | |

Theoretical capacity | cm3 | 209 | 256 | 294 |

Injection weight | g | 190 | 233 | 267 |

Injection Pressure | MPa | 243 | 199 | 173 |

Injection rate | g/s | 100.9 | 123 | 141.2 |

Plasticizing capacity | g/s | 14.7 | 18.2 | 20.6 |

Max. screw speed | rpm | 200 | ||

Clamping force | kN | 1280 | ||

Moving mould distance | mm | 560 | ||

Tie bar spacing | mm | 420×420 | ||

Max.Daylight | mm | 730 | ||

Min. mould thickness | mm | 170 | ||

Ejector stroke | mm | 150 | ||

Ejector force | kN | 41 | ||

Ejector bar amount | 5 | |||

Max.pump pressure | MPa | 17.5 | ||

Pump motor power | kW | 15 | ||

Heating power | kW | 7.5 | ||

External dimension | mm3 | 4500×1600×2100 | ||

Weight | Kg | 5500 | ||

Material cylinder capacity | L | 25 | ||

Oil tank capacity | L | 265 | ||

Package of PLASTIC INJECTION MOLDING MACHINE-C SERIES

Wooden box packed, suitable for train or sea worthy delivery.

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Are the fragrance of poisonous substances poisonous in plastic products?

- Poisonous, smelling, and dying so fast, so many people with mechanical hand out, we repair the manufacture of mechanical hand

- Q: I'd like to open a plastic bag factory. How much do I need to buy the equipment?

- It depends on what plastic bags you need to make, and the size and size of the big plastic bags are also crucial. I make plastic bags.

- Q: How much does it cost to process disposable plastic bags?

- The package of blow molding machine, cutting machine, switchboard, mixing machine totaling about 120 thousand

- Q: I want to use POM plastic to do mechanical disc cam, processed with sheet metal. (small dosage)Do other plastics have mechanical strength?

- Can be processed, but pay attention to cutting tools to be sharp, cutting force should be small, and fully cooled.The material is of good mechanical strength, and I know nothing in the plastic can match it.

- Q: How much profit can a ton earn? Is it difficult to operate the program?

- This machine is mainly used for classification, after crushing, washing, dewatering and drying of PET sheet for processing our company successfully developed a new generation of "PET bottle recycling unit, this machine adopts fully closed, the whole production process without spray, no noise, waste bottle with PET as raw material. With high yield: SJL150 type can produce about 400 kilograms per hour, the product quality is good: the particles are white, transparent, good color, low energy consumption.Selection process: coke bottle, oil bottle, mineral water bottles and other various beverage bottles and etc.. 1. the outside trademark tear, these trademarks are mostly PVC, namely PVC shrink film 2. second were crushed, began to shatter the heart must bring water flushing to some other 3. other third step of removing sludge washed 4. refractory impurities fourth steps and then washed with water to the dryer to dry the water bag 5. (ball) into the vacuum oven drying 6. spinneret, setting 7. hot water steam shift extension, setting 8. wire into the packaging machine packing label factory after weighing 9.

- Q: I want to make some plastic products. Thank you。 FiveThe four type: first, a one or two meter long, hard, but bent plastic tube. Then there's something like the front end of the syringe. And then a small plastic kettle. Finally, a small thing that can be secured to the mouth of the pipe.

- The first thing for PE is certainly no problem, PE pipe can be bent, there are a variety of diameters and specifications to the number of how many, still a little hard oh.

- Q: What kind of equipment do we need? How much is the approximate cost? Seek your heroes guidance and guidance!

- Equipment include: film blowing machine, bag machine, punching machine, printing machine, etc., to invest one hundred thousand up and down, but also need a few tons of raw materials as a turnover, and then start production, I do not know very well, just listen to someone else said...

- Q: What kind of machinery does a plastic product factory need?

- See what you want to do, there are blown film, tape casting, calendering, molding, injection molding...... A great deal of

- Q: In Shengze where you can find what rags processed into a plastic factory

- You mean it woven rags! Use a plastic granulator.

- Q: How do we calculate the cost?

- So many people bought equipment and started, most of the friends have just started, mainly chemical fiber bags (PP woven bags) granulation, plastic film granulation, plastic bottles, broken materials, and so on.2, followed by the main problem is the use of equipment:1). Performance of the equipment are not familiar with the problems of using too much, such as temperature control is not good (low price devices do not have automatic temperature control system, through experience), products can not achieve the desired requirements, the color is not good, drawing off a serious, low yield, often blocking filter, cutting unevenness, severe adhesion.2) raw materials sorting is not clear, cleaning is not in place, impurities, broken bar serious, bad color. The same raw materials, the same approach, the product is not as good as others, the price is far from.3), procurement of raw materials, usually all recycled plastic, when you formed a batch production, to ensure the supply of raw materials can not be too much, impurities in raw materials procurement, and even pit you encounter people, buy a home is water, stone bag.4) sales problems: I don't know who sells the products. I don't know what the price is, or even say you have such and such problems.Moreover, the beginning of production, it is impossible to form mass production, small amount of bad sales, because customers need to be generally enough to a car to load, 2T-3T is not good, and more afraid of production, fear of backlog.

Send your message to us

Large two-platen (Direct Hydraulic Clamping) Injection Moulding Machines

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 SET unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords