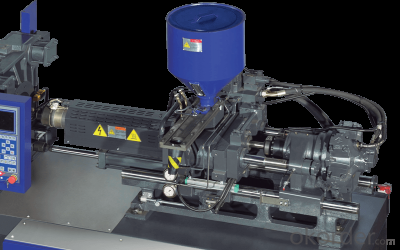

All-Electric High Precision Injection Moulding Machines

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Description of All-Electric High Precision Injection Molding Machines

Introduction

1.Reliable plastic injection machine with servo motor ,equiped with servo motor , closed loop control for pressure and flow .low noise,high precision and energy saving .

We design,manuafcture and supply our own brand of injection molding machine with clamping force ranged.

2.Inject all kinds of plastic parts, bottle preform, engineering plastic, UPVC, PVC, PE pipes fitting, omponents for automotive, household, eletronics, telecommunication, ETC

Advantages&Traits of All-Electric High Precision Injection Molding Machines

Control part:

1.It adopts imported computer for plastic injection machine , with large screen . high definiyion crystal display and human-computer interface in different languages. Through CPU independent control and individual treatment. It has raised the running speed of thr control system and alarming of successive oil temperature , thus I,proving the operating speed of the machine.

2. Closed –loop temperature control system to ensure the accuracy and reliability of the barrel temperature . The functions of cold –proof boot, alarming and parameter memory for the molding, with password protection. The injection and switch are controlled by imported ruler.

Injection part:

1.The excellent chrome , molybdenum and aluminum alloy screw and barrel have undergone the nitrilizing process, applicable to various plastic materials.

2. The injection cylinder(258T advanced) is parallel or balance for both sides of the barrel, so as to ensure the non-deviation of thr nozzle, good sealing and non-leadage. It is equipped with double guide pillar supporting system which can inject under multifarious pressure at various speeds. It also uses one-stop hydraulic pre-injection device.

Hydralic part:

It adopts the imported top quality hydraulic components, proportional control for pressure and flow.

Moulding-adjusment part:

Mold is adjusted by gear controlled by oil motor , the mold can be adjusted automatically in accordance with the setting pressure , which is both convenient and reliable.

Mold part

1.Five –fulcrum crankshaft structure , the mold and bracket structure together,with good rigidity and high-fitting precision, adopting the computerized optimized design. The mold employs finite element analysis, with double pulling and inserting device.

2.Perfroms thefunctions of super sensitive low pressure protection. The mechnical hydraulic and electrical protection have the human safety. The dismounable fill-out hopper can be installed conveniently and automatically.The moveable platen adopts a fixed durable vertical brace that is adjustable. With little friction and balanced dependable moving. Clamp opening is synchro with ejection.

Specification of All-Electric High Precision Injection Molding Machines

Item | Unit | Parameter | ||

Screw no | A | B | C | |

Screw Dia | mm | 38 | 42 | 45 |

Screw LD ratio | 23.2 | 21 | 19.6 | |

Theoretical capacity | cm3 | 209 | 256 | 294 |

Injection weight | g | 190 | 233 | 267 |

Injection Pressure | MPa | 243 | 199 | 173 |

Injection rate | g/s | 100.9 | 123 | 141.2 |

Plasticizing capacity | g/s | 14.7 | 18.2 | 20.6 |

Max. screw speed | rpm | 200 | ||

Clamping force | kN | 1280 | ||

Moving mould distance | mm | 560 | ||

Tie bar spacing | mm | 420×420 | ||

Max.Daylight | mm | 730 | ||

Min. mould thickness | mm | 170 | ||

Ejector stroke | mm | 150 | ||

Ejector force | kN | 41 | ||

Ejector bar amount | 5 | |||

Max.pump pressure | MPa | 17.5 | ||

Pump motor power | kW | 15 | ||

Heating power | kW | 7.5 | ||

External dimension | mm3 | 4500×1600×2100 | ||

Weight | Kg | 5500 | ||

Material cylinder capacity | L | 25 | ||

Oil tank capacity | L | 265 | ||

Package of All-Electric High Precision Injection Molding Machines

Wooden box packed, suitable for train or sea worthy delivery.

FAQ:

1. Why Choose us?

CNBM is a stated owned company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

3. Can you provide sample?

Yes, we can offer free sample for you.

4. Payment terms?

We can accept L/C, T/T etc.

5. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: I am engaged in the plastic processing industry, mainly for ABS and PP through chemical agent for processing, will this be harmful to the body?

- Alkyl tea sulfonate (ABS) can not only poison the body, but also promote carcinogenic effects of carcinogens. Recently, it has been found that ABS also has the risk of teratogenic changes.Polypropylene (PP) itself is non-toxic, but I do not know what you say powder ingredients, if there are plasticizers, masterbatch and the like, there is a certain toxicity.In the production of ABS containing detergent factory, should pay attention to do a good job of environmental protection, adopt cleaner type production process, in the production process to be closed, to reduce the concentration of ABS in the air of workplace and workers to do protective measures.

- Q: Is it gear oil or general oil?Inside the old oil is relatively thin, the new gear oil is relatively thick. Can you add?.Please point out.Should we add "ordinary gear oil" or "hyperbolic"?

- You should clean up the old oil and add gear oil. Because gear oil increases the service life of the gear in the gear reducer.

- Q: Plastic POM POM generally used for the production of what plastic products?

- POM used in the lubrication, abrasion resistance, rigidity and dimensional stability requirements more stringent sliding and rolling mechanical components, the performance is very superior, mainly used for industrial machinery, automobile, electronic and electrical, plumbing and irrigation supplies etc..Pom Pom Pom name (POM) also known as steel, special steel. It is based on formaldehyde and other raw materials for polymerization. POM-H (POM homopolymer), POM-K (polyoxymethylene copolymer) is a thermoplastic engineering plastics of high density and high crystallinity. Good physical, mechanical and chemical properties, especially excellent resistance to friction.POM is a non - chain, high-density crystalline polymer with excellent comprehensive properties.POM is a smooth, shiny hard and dense material, light yellow or white, can be used in -40- 100 degrees C temperature range for a long time. Its abrasion resistance and self lubrication are superior to most engineering plastics, and it also has good oil resistance and peroxide resistance. Very acid free, alkali resistant and UV resistant. (adding UV can greatly improve its ultraviolet resistance rating)

- Q: Plastic food bags processing machines where there is ~ how much is the price, I know

- You mean the production of food bags? A machine or a sealing machine? Vacuum packaging machinery, food packaging bags, I can provide you with!

- Q: from raw material to particle forming, need several devices, what are they? _?

- No cleaning, no cleaning equipment. Then, granulation, granulation machine granulator. There is pollution, smell must be yes, in the living quarters, certainly you can not go on. Remember, there must be three-phase electricity, in less people place production, third, cleaning sewage discharge.There are many details, specifically you learn it yourself. You can sell it. It's sure to make money.

- Q: What milling cutters are used for processing plastics?

- In fact do not wear too to pay attention to the water to keep up. Try to use high speed low cutting depthThe speed is 8000/, the cut depth is 0.3-0.4, and the 4000 is the best

- Q: Why is the dimensional accuracy of molded plastic parts much lower than the accuracy of machined products?

- Because the plastic parts in the production process has obvious phenomenon of thermal expansion and contraction, mold design and manufacture in human made amplification processing, the magnification according to the important performance index of plastic shrinkage rate, which is a statistical index, and unstable. Therefore, the precision of plastic products is lower than that of machined products by 1~2 grades.

- Q: Please expert pointing. How high is the profit?. Where are the machines reliable in quality?.

- Profit is not to say, 2000 before doing a ton of 500-1000 net profit, now do a ton of only about 300, but also to do good, large amount of the profit was also lower (puerile) now what things are transparent, not hide what the difference, and too many fakes (it is impurity) also, the factory debt, lead to large investment (scrap price is high, the factory as a result of the large investment in arrears), reliable quality machine: if the water feed on a number of Shandong (lack of the low yield), if the dry material (sheet) on a number of Guangdong Zhongshan presses, the Chinese star can also.

- Q: How do we calculate the cost?

- Four major matters needing attention in investment of recycled plasticsPlastic recycling is a sunrise industry, the country, not only the effective utilization of resources and protect the environment, reduce the white pollution, from 2004 recycled plastics market, considerable benefits, as a new way of friends, is the author contact situation (editor's note), there are many aspects should be prepared in the first period, not to fight the battle without. The main problems are concentrated in the following aspects:1, blind follow-upAccording to the renewable materials market in 2004 prices, had been recycled most of the people have a better income, as for friends, in the test stage, on the surface has the advantages of simple process, low equipment investment, the product basically in short supply, technology content is not high, ordinary people can do at the same time, the raw material is us around the most familiar things, everywhere, everywhere can buy. Rough calculation, such as waste 2000 yuan can receive, the product can sell 4000 yuan, absolutely profitable.

- Q: Is there a difference in melt index before and after processing?

- If no additives are added during processing, the melt index is the same as that before processing.

Send your message to us

All-Electric High Precision Injection Moulding Machines

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords