Mullite Silica Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

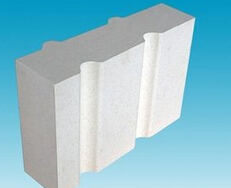

Mullite Brick(lightweight refractory brick )

1.Classification tempe: 1300~1600C

2.Density:600~1100kg/m3

3.Size:230x114x64mm

Mullite Brick is made from high-grade and high purity refractory powders and materials. During the process of production, organic and multiple filling materials are injected accoridng to the required proportion. LUYANG mullite brick is compressed in vacuum and sintered under high temperature.

Application

Lining and back lining of various furnaces in the industry of metallurgy,petrochemical,ceramics,machinery and building materials.For instance:

the cracking furnace,conversion furnace, heating equipment,refining equipment,reproduction equipment,hot blast stove,heating furnace, tunnel kiln,shuttle kiln,glass-pool kiln,tec

Standard Specification

Grade: 23,26,28,30,32

Classification temperature:1300/1400/1500/1550/1600

Size: 230x114x65mm

Density: 600-1100kg/m3

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- Small fluctuations in the chemical composition do not have a significant effect on use. The key is the operation of the electrolyzer in production to determine whether the side wall will be damaged.

- Q: The introduction of silica brick

- The characteristics of silica brick:Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.The use of silica brick:Mainly used for masonry brick oven carbonization chamber, a combustion chamber and a partition wall, glass furnace and kiln roof, pool wall, high temperature hot blast furnace, glass furnace, load-bearing pool wall, hot blast stove, baking furnace of carbon bearing part of high temperature furnaces etc.. Rongsheng with refractory

- Q: How much is the highest melting point of silicon?

- Mainly used for partition, carbonization chamber of coke oven and combustion chamber open hearth furnace regenerator and a sediment chamber, soaking furnace, glass melting furnace refractories and ceramic kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace

- Q: The United States of our brick anti-dumping duties?

- . According to the relevant legal procedures, the United States International Trade Commission will make a final ruling on the anti dumping industrial injury before January 6, 2014, if an affirmative determination, the U.S. Department of Commerce will be involved in product release tax anti-dumping order.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: Can iron oxide be used as refractory material?

- Iron oxide can not be used as refractory material, but it can be used as refractory additive. Iron oxide can be used as pigment

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Tridymite content high thermal conductivity silica brick is 70%, tridymite content of traditional brick is 60%, tridymite content high thermal conductivity of silica brick than tridymite high content of 10% traditional brick,

- Q: Can not use it two brick

- Acidic silica brick refractory material, has good ability in acid slag erosion

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

- Q: The formula in the refractory brick, and firing curve, who knows?

- Add 1.8-2.2% of the total weight of the main raw material, and then add lime milk, rolling for 10-15 minutes, and finally add pulp, rolling for 10-15 minutes, out of the mill, forming billet.

Send your message to us

Mullite Silica Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches