Corundum-Mullite Brick for Industrial Furnace Lining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

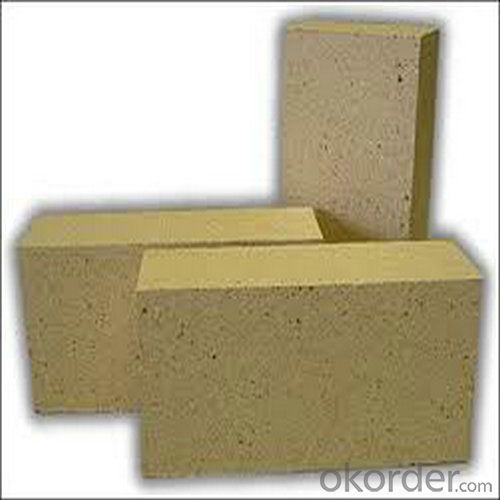

Description of Corundum-Mullite Brick

CMAX corundum-mullite bricks use the high-purity corundum as the main raw material, and are produced by advanced technology.

Features of Corundum-Mullite Brick

Low thermal conductivity

High strength

Good thermal shock resistance

Applications of Corundum-Mullite Brick

CMAX Insulating Firebricks can be used as Industrial furnace lining and Glass furnace

Specifications of Corundum-Mullite Brick

Models | A-1 | A-2 | A-3 | A-4 | A-5 | |

Classification Temperature (°C) | 1260 | 1430 | 1540 | 1650 | 1760 | |

Bulk Density (g/cm3) | 0.55-0.60 | 0.78 | 0.88 | 1.03 | 1.25 | |

Cold Crushing Strength (Mpa) | 1.2 | 1.6 | 2.1 | 2.5 | 3.5 | |

Modulus of Rupture (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

Reheating Linear Change (%) CT-30 °CX 8H | 1230°C -0.5 | 1400°C -0.5 | 1510°C -0.5 | 1620°C -0.9 | 1730°C -0.9 | |

Thermal Expansion 1000°C(%) | 0.5 | 0.7 | 0.8 | 0.9 | 1.1 | |

Thermal conductivity(W/m.k) | 400°C | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

600°C | 0.16 | 0.29 | 0.34 | 0.43 | 0.5 | |

800°C | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

1000°C | 0.20 | 0.33 | 0.38 | 0.45 | 0.53 | |

Al2O3 (%) | 37 | 58 | 67 | 73 | 77 | |

Fe2O3 (%) | 1.0 | 1.0 | 1.0 | 0.5 | 0.4 | |

Images of Corundum-Mullite Brick

FAQ of Corundum-Mullite Brick

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a general idea of the specification and technical data of your products?

CNBM offer a range of refractory and insulation products. We provide refractory bricks, monolithic refractories as well as ceramic fiber products. And On your given shapes, drawings or description, we are producing refractories with all sizes and shapes, resistant to temperature from 800 °C till 1800 °C, using various machines and equipments for cutting, grinding, drilling, polishing, shaping processes.

Every refractory product by CNBM is of superior quality. Lesser refractory products can not approach. CNBM utilizes proprietary testing methods, testing for chemical content, density, apparent porosity, cold crush strength and modulus of rapture. With stringent quality control, you can count on CNBM products to exceed refractory industry standards and your expectations.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: Mullite bricks in alumina alumina is what?

- With mullite as main crystalline phase of high alumina refractory products. Mullite bricks containing Al2O3 64%~75%, refractoriness >1790? C, normal temperature compressive strength 70~260MPa, softening the starting point for 1600~1700 degrees. The manufacturing method for casting and sintering process.

- Q: What are the properties of corundum mullite?

- Heavy material has good compactness, high compressive strength, resistance to various corrosive gases, good thermal shock resistance, good thermal conductivity and wear resistance.

- Q: Corrosion mechanism of iron on refractory materials

- Iron oxide can not be used as refractory,

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color. For example: 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more

- Q: 2000 degree of high temperature materials, which belong to high temperature insulation materials?

- Magnesium compounds, ceramics, mica, corundum, silicon, graphite, titanium alloy, diamond, tungsten, silicon dioxide, silicon carbide, carbon, copper oxide, iron oxide, iron, manganese, lightweight mullite corundum brick, high aluminum brick lightweight clay brick, alumina hollow ball1) rock wool board: thermal conductivity 0.041-0.045, fire retardant, fire resistance, temperature absorption, insulation effect is poor.(2) glass wool: construction is simple, free cutting. Antibacterial, mildew proof, aging resistance, corrosion resistance, and guarantee the healthy environment. Low hygroscopicity and stable physical properties.

- Q: What material is heat insulated and not afraid of fire?

- Foam as a kind of important organic insulation materials, there are two kinds of polystyrene and polyurethane foam, which was published in 30s, the production in our country began in late 50s and 60s, which is characterized by the effect of thermal insulation performance, light weight, sound absorption properties, but the organic materials and brick wall with construction is difficult. Need the polystyrene foam plate is adhered in the walls with special binder and coupling agent, after a plurality of process, the construction is very complex. Moreover, foam plastic products have poor aging resistance, low service life, and waste materials can not degrade and cause white pollution.

- Q: What are the high temperature insulation materials?

- Followed by a variety of lightweight bricks, alumina hollow ball, lightweight brick is relatively high temperature, about 1600 degrees. The others are low.Then there's the heavy brick. Heavy alumina brick, corundum mullite, can withstand 1750 degrees -1800 degrees. Mullite, cordierite lower lows.

- Q: What kind of refractory material is used in the hearth of reverberatory furnace?

- 1400 degrees below can use clay brick, high alumina brick; 1400 to 1700 can use mullite bricks, heavy corundum brick; more than 1700 can use zirconia brick, such as zirconia brick

- Q: What material is good for refractory bricks?

- Is the main varieties of acidic silica brick, refractory brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.

Send your message to us

Corundum-Mullite Brick for Industrial Furnace Lining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords