Most Popular 2024 XPS Boards - Extruded Polystyrene

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | XPS Boards | Place of Origin: | Brand Name: | ||

| Model Number: | MXPS | Thickness: | 20mm-70mm | Color: | As your request |

| Density: | 30-65kg/m2 | Width: | 450mm-1200mm | Length: | 1200mm-6000mm |

| Compressive Strength: | 200kpa | Name: | xps extruded polystyrene board | Moisture permeability: | ≤3.0 |

| Water absorbability: | ≤0.5 | Dimensional stability: | ≤1.0 |

Packaging & Delivery

| Packaging Detail: | XPS Foam Board packing: Plastic bag,62-65 cubic metre per 40 Feet Container |

| Delivery Detail: | Within 10 days after T/T deposit for XPS |

Specifications

XPS foam board

Outdoor insulation board

Keep warm and insulate heat

Green environmental protect

Fire prevention

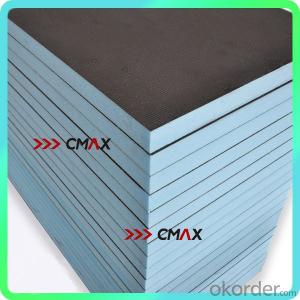

2014 Most popular xps extruded polystyrene board

Description

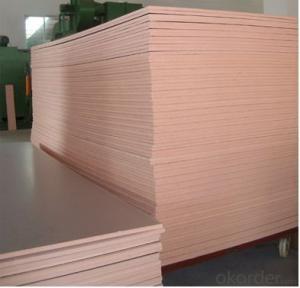

Xps foam board is an asbestos-free insulating material reinforced with XPS and EPS bottom designed

to provide excellent thermal & heat resistance, fire & sound insulation for a wide range of decoration requirements.

Description

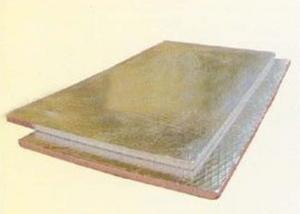

1.Material:XPS&EPS bottom,Inorganic resin plate, ceramic top, composited materials

2.Standard Size: 300mm * 300mm 300mm * 600mm 400mm * 800mm

600mm * 600mm 600mm * 1200mm

3.Edge Treatment: Flat(SS) type, Overlap Joint(SL) type, TG Tenon type

4.Surface Treatment: Smooth(with skin) / Roughening(without skin)/

Line groove surface/ Special embossing surface

5.Color: Pink (normal color), White, Light grey, Light yellow, Sky blue, others (can be customized)

6.Certification: CE / CSA

7.Use: Widely used in wall insulation, low-temperature storage facilities, parking platform,

the airport runway,highways etc.

Main Characteristics

1. Good alkali / acid resistance

2. Good weather resistance (anti-thawing, anti-freezing)

3. Stable dimension, low expansion rate, low contractibility

4. Good stain-resistance, self-clean ability

5. Natural appearance, uniformed color

6. Excellent fire-proof performance

7. Durable, long service life

8. Easy to be processed

9. Eco-friendly

10. Easy installation

XPS Procedure

Advantages

1. high compression resistance

2. moisture-proof

3. airtight

4. non-absorbent

5. corrosion resistance

6. low thermal conductivity

7. lightweight

8. Life time:60 years

9. environmentally friendly

- Q: 25 thick extruded polystyrene plastic insulation board how many kilograms per cubic meter

- Sandwich board is made of color coated board, stainless steel and other materials as the surface of the composite board, because of its unique dust, anti-static, anti-bacterial effect, is widely used in electronics, pharmaceuticals, food, biological, aerospace, precision Equipment manufacturing and scientific research on the indoor environment demanding clean engineering areas

- Q: How is the flame and combustible defined by the naked eye? I burn the B1 level and B2 level XPS board is different? Question added: detection time is longer, can quickly and intuitively identified? More

- Mainly for insulation to reduce heat loss. So use a good insulation material insulation. Hope it helps you.

- Q: I set up in October 2008, the production of XPS board - that is, with the extinction of polystyrene foam plastic plate, is an energy-saving environmental protection materials. Consult experts: I can enjoy the relevant tax incentives?

- the inner wall insulation, as the name suggests is the wall inside the house Hu Dangan citrus spinning song dead building, the use of spraying, bonding, pouring, etc

- Q: Sound insulation and polystyrene insulation board which sound insulation better?

- Can be considered ultra-fine inorganic fiber spraying, this insulation material is sprayed up, not limited by the shape of the building, the speed is still fast

- Q: Steel plant wall plug color steel tile, the glass glass inside the glass, hanging in color steel, how construction? How is the cost associated with a single sandwich panel?

- More than 24 meters need to use cantilevered scaffolding, and the spacing of not more than 20 meters

- Q: Extruded Polystyrene Board, Polystyrene Foam Board and Expanded Polystyrene Board

- Market price, no quota. According to the different brands, the price is different! I hope useful to you!

- Q: Polystyrene foam hard insulation board will not be harmful to the human body, right?

- Online under ah ~ ~! A few days ago I have a ~ ~!

- Q: What is the difference between an extruded board and an XPS extruded board?

- 1. Civilized construction program 2. Safe construction program 3. Template construction program 4. Scaffolding construction program 5. Sambo four construction program 6. Temporary electricity construction program 7. High operating construction program 8. Tower crane construction plan 9. Multi-tower operation anti-collision construction program 10. Emergency emergency plans 11. Winter rainy season construction program 12. Significant hazard assessment measures 13. Construction organization design 14. Building energy conservation program 15. Basket construction program 16. Tower crane hoisting program

- Q: Steel structure rock wool sandwich wall panel what the amount of this set

- Generally in the 100-300 yuan / cubic or so, 60 mm thick is 6-18 yuan / square or so Specifically look at how much you use the density of the Polystyrene foam board - also known as foam board, EPS board is made of volatile liquid blowing agent containing polystyrene beads, heated by the preheated in the mold after heating the formation of white objects, its fine The structure of the obturator is mainly used for building wall, roof insulation, composite board insulation, cold storage, air conditioning, vehicle, ship insulation, floor heating, widely

- Q: How to distinguish between good and bad insulation board insulation board

- Class flexible management refers to the class teacher in the student's psychological and behavioral laws on the basis of the use of non-mandatory way, in the minds of students to produce a potential persuasive, the use of the class teacher's own positive factors to influence and guide students

Send your message to us

Most Popular 2024 XPS Boards - Extruded Polystyrene

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords