Honda Solar Cells - Monocrystalline Solar Cell-Made at Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 10000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Advantages of Poly Solar Cells

1.CNBM Solar improves cell-to-module ratio by:

2.Narrowing down efficiency bin range to 0.2%.

3.Defining efficiency bins by minimal power and 97% of current at maximum power.

4.Customers can manage and control module power output distribution.

5.Customers get more value for their money.

6.Long-Term Reliability

7.High Shunt Resistance

8.Low LID (Light-Induced Degradation)

9.Frequent internal monitoring of LID.

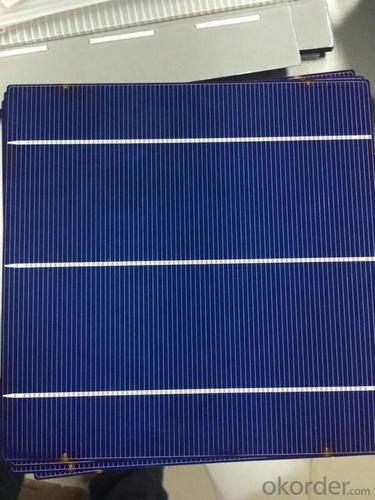

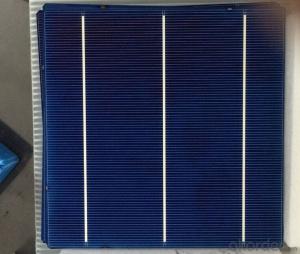

Specifications of Mono Solar Cells

Format :125 mm × 125 mm ± 0.5 mm

Thickness: 210μm ± 40 μm

Front (-) :1.5mm bus bars (silver),blue anti-reflection coating (silicon nitride)

Back (+): 2.5mm wide soldering pads (silver) back surface field (aluminium)

Temperature Coefficient of Mono Cells

Voc.Temp .coef.%/K: -0.351%/K

Isc.Temp .coef.%/K: +0.035%/K

Pm.Temp. coef.%/K: -0.47%/K

Usage and Applications of Monocrystalline Cells

Solar cells are often electrically connected and encapsulated as a module. Photovoltaic modules often have a sheet of glass on the front (sun up) side, allowing light to pass while protecting the semiconductor wafers from abrasion and impact due to wind-driven debris, rain, hail, etc. Solar cells are also usually connected in series in modules, creating an additive voltage. Connecting cells in parallel will yield a higher current; Our solar cells have passed IEC Certification. With high quality and stable quality. Our Cells can greatly improve the performance of Solar Modules.

Packaging & Delivery of Monocrystalline Cells

Carton Box Package and Deliver by air. It should be noticed that it should be avoid water, sunshine and moist.

FAQ: What's your products warranty?

•: No less than 90% within 10years and no less than 80% within 25years. Less power decrease.

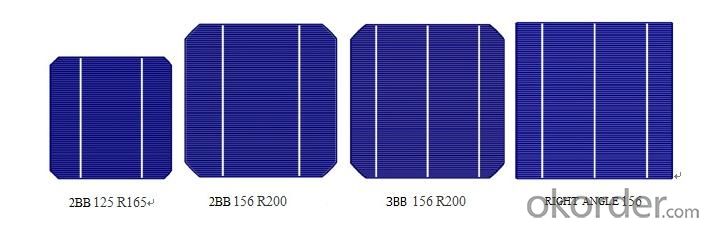

FAQ: How many kinds of solar cells can we produce?

•: We can supply the normal 2 kinds of solar cells, Poly 156mm*156mm and Mono 125mm*125mm , and the special dimensions also can be produced .

FAQ: What's the efficiency range of the solar cells?

•: We can supply 16.8% to 18.9% efficiency of the solar cells.

Solar cell materials and the part of the function

1) Tempered glass whose role is to protect the main power, the choice of which is light-transmissive requirements: The light transmittance must be high (generally more than 91%); super white steel processing.

2) EVA is used to bond glass and generation fixed body, transparent EVA material directly affect the life of components exposed EVA in the air easily aging yellow, thus affecting the transmittance components thus affect the quality of power generation components in addition to the EVA itself, the quality, the laminating process on the component manufacturers is very large, such as the degree of non-compliance EVA glue, EVA and glass, back bonding strength is not enough, will cause EVA early aging affect component life. The main body and the bonding package power backplane.

3) Cells main function is to generate electricity, the electricity main market is the mainstream crystalline silicon solar cell film, thin film solar cells, both have their advantages and disadvantages. Crystalline silicon solar cells, the equipment cost is relatively low, the photoelectric conversion efficiency is high, outdoors under the sun power is more appropriate, but the consumption is high and the cost of solar cells; thin-film solar cells, battery consumption and low cost, very low-light effect well, in ordinary light can also generate electricity, but the relatively high cost of equipment, photoelectric conversion efficiency of crystalline silicon solar cells is relatively more than half of the points, such as solar calculator.

4) The role of the backplane, sealing, insulation, waterproof (usually with TPT, TPE and other materials must be resistant to aging, most of the components are factory warranty for 25 years, tempered glass, aluminum is generally no problem, the key in the backplane and whether silicone can meet the requirements.)

5) Protection of aluminum laminate, play a seal, supporting role

6) Junction box to protect the entire power generation system, play a role in the current transfer station, a short circuit if the component junction box automatically disconnect the short-circuit the battery string, then the entire system to prevent burn out, the box is the most critical diode selection, according to internal components different types of cells, and the corresponding diode is not the same.

7) Silicone seal for sealing components and aluminum frame, junction box and wiring components Some companies use double-sided tape, foam instead of silicone, domestic widespread use of silica gel, the process is simple, convenient, easy to operate, and the cost low.

- Q: Can solar cells be used in combination with batteries?

- Yes, solar cells can be used in combination with batteries. Solar cells convert sunlight into electrical energy, which can be used to charge batteries. This allows for the storage of excess solar energy during the day and the use of that stored energy during nighttime or when sunlight is not available.

- Q: How do solar cells perform in areas with high winds?

- Solar cells can perform well in areas with high winds, as long as they are properly installed and secured. The design and installation of solar panels take into consideration factors like wind load and durability. Additionally, some solar panels are specifically designed to withstand high wind speeds. However, excessively strong winds can potentially damage or displace solar panels, so it is important to ensure proper installation and maintenance to maximize their performance and longevity in such areas.

- Q: Where can I get a competitive price for this solar cell? The 2bb/3bb polycrystalline solar cell panel?

- 2bb/3bb polycrystalline solar cell panel is a conventional solar cell you can basically get anywhere, but mostly it is produced in China.

- Q: We are currently promoting our one of our solar cells seriers, which is the 156mmx156mm 6inch,2BB/3BB polycrystalline/multi solar cells,mono solar cell,made in Taiwan/Germany, please feel free to contact me if any interest.

- Are the dimensions accurate? Can it be tailor-made if I want a different size? Maybe you can send me more information?

- Q: What are the disadvantages of using solar cells?

- One disadvantage of using solar cells is their high initial cost. The installation and setup of solar panels can be expensive, making it less accessible for some individuals or households. Additionally, solar cells are dependent on sunlight, so their efficiency can be affected by weather conditions, such as cloudy days or limited sunlight during winter months. Moreover, the production of solar cells involves the use of certain materials that can have environmental impacts, such as the extraction of rare minerals. However, advancements in technology and decreasing costs are gradually reducing these disadvantages and making solar energy a more viable option for sustainable energy production.

- Q: Can solar cells be used in off-grid applications?

- Yes, solar cells can definitely be used in off-grid applications. Off-grid systems rely on renewable energy sources like solar power to generate electricity independently from the main power grid. Solar cells, also known as photovoltaic cells, convert sunlight directly into electricity and can be used to power various off-grid applications such as remote cabins, boats, or even outdoor lighting systems. The ability of solar cells to operate without the need for a connected power grid makes them ideal for off-grid scenarios where access to electricity is limited or unreliable.

- Q: Can solar cells be used for powering remote mining operations?

- Yes, solar cells can be used for powering remote mining operations. Solar energy is a reliable and sustainable power source that can be harnessed in remote locations where traditional power infrastructure is unavailable or costly to implement. Solar panels can generate electricity during daylight hours, which can be stored in batteries for use during nighttime or cloudy periods. This makes solar cells a practical and eco-friendly solution for powering remote mining operations, reducing reliance on fossil fuels and minimizing the environmental impact.

- Q: How do solar cells impact local economies?

- Solar cells can have a positive impact on local economies in several ways. Firstly, the installation and maintenance of solar panels create job opportunities, boosting employment rates and income levels in the local community. Additionally, solar energy reduces dependence on imported fossil fuels, which in turn decreases energy costs for businesses and residents, leading to increased savings and disposable income. Moreover, solar power can attract investments and promote the development of local solar industries, thus stimulating economic growth and innovation. Overall, solar cells contribute to a more sustainable and prosperous economy at the local level.

- Q: Can solar cells be used for powering remote research stations?

- Yes, solar cells can be used for powering remote research stations. Solar cells, also known as photovoltaic cells, convert sunlight into electricity, making them an ideal and sustainable power source for remote locations. Solar panels can be installed at the research station to capture sunlight and generate electricity, which can then be stored in batteries for use during periods of low sunlight or at night. This enables the research station to operate independently of traditional power grids, reducing reliance on fossil fuels and providing a clean and renewable energy solution.

- Q: What is the impact of bird droppings or debris on solar cell performance?

- Bird droppings or debris on solar cell panels can significantly impact their performance. The droppings can create a layer that blocks sunlight from reaching the cells, reducing their efficiency in converting solar energy into electricity. Additionally, the debris can accumulate over time and create shadows on the panels, further decreasing their output. Regular cleaning and maintenance of solar panels are essential to maximize their performance and ensure optimal energy production.

Send your message to us

Honda Solar Cells - Monocrystalline Solar Cell-Made at Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 PCS

- Supply Capability:

- 10000000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords