Mirafi 160N PP/PET Nonwoven Geotextile with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geotextile Introduction

PP/PET Geotextile has excellent permeability, acquired, durability, which can be widely used in railway ,highway, movement hall,Dams,hydraulic structures hence hole, coastal shoal, reclamation,environmental protection and other projects. The main products are Synthetic staple fibers needle punched nonwoven geotextiles and split film yarn woven geotextiles.

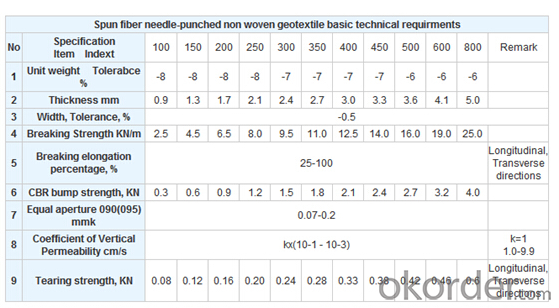

Geotextile Specification

1. Weight: 100g~1500g

2. Width: 1m ~ 7m

Product Package:

Packing: Plastic film inside & Woven bag outside.

Shipping: About 15 days after receipt the deposit

Geotextile Application

Geotextile Application

Filtration

Separation

Adding

Protection

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are freee, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Where is the geotextile

- Essence is also the beauty of the latest brand of science and technology crystallization of the product

- Q: What is the geotextile of polypropylene gb / t?

- GB / T-2017 Geosynthetics Static Crack Test (CBR Method) This standard specifies the method of measuring the breaking strength of geosynthetics by flat top pressing bar. This method is usually carried out on samples that specify the standard atmospheric humidity. This standard applies to all types of geosynthetics, but does not apply to materials with a pore size greater than 10mm.

- Q: What are the regulations for geotextiles in construction projects?

- The regulations for geotextiles in construction projects vary depending on the country and region. However, in general, geotextiles must meet certain standards and specifications to ensure their effectiveness and safety. These regulations typically include requirements for strength, durability, permeability, and compatibility with the specific construction application. Additionally, geotextiles may need to comply with environmental regulations, such as restrictions on harmful substances or disposal methods. It is essential to consult local building codes, industry standards, and relevant authorities to determine the specific regulations applicable to geotextiles in a construction project.

- Q: Geotextile what is the law?

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. The American Society of Agricultural Engineers defines geotextiles as geotextiles or geosynthetics that exist between soils and pipelines, gages, or retaining walls that enhance water movement and impede soil movement. ASTM 4439 standard geotextile is defined as: a purely permeable geosynthetics to form textiles. Is used in soil, rock, soil or other geotechnical engineering related materials and acts as a component of a human-made project. Geotextile is a new type of building materials, raw materials are polyester, polypropylene, acrylic, nylon and other polymer polymer synthetic fiber. In accordance with the manufacturing method is divided into: there are two types of geotextile and non-woven geotextile. General engineering is mainly used non-woven geotextile. Geotextile with filter, filter, isolation, reinforcement, protection, sealing and other functions.

- Q: Can geotextiles be used for erosion control in mining sites?

- Yes, geotextiles can be used for erosion control in mining sites. Geotextiles are commonly employed in mining operations to stabilize the soil, prevent soil erosion, and control sedimentation. They can effectively reduce the impact of erosion caused by wind, water, and other environmental factors, thereby helping to maintain the integrity of mining sites and minimize environmental damage.

- Q: Designers give blind ditch length of 540m, geotextile for 2835m2 more

- Too professional. You ask the manufacturers, music built

- Q: What are the different geotextile reinforcement techniques?

- Some of the different geotextile reinforcement techniques include mechanical stabilization, soil confinement, and erosion control. Mechanical stabilization involves using geotextiles to increase the strength and load-bearing capacity of soils, such as in road construction or retaining walls. Soil confinement refers to the use of geotextiles to prevent soil erosion and maintain the stability of slopes or embankments. Erosion control techniques involve using geotextiles to protect soil surfaces from the erosive forces of water or wind, helping to maintain the integrity of the landscape.

- Q: Where to find the right geotextile

- Geotextile types are many, according to the manufacturing process of spinning, woven, woven, according to the material is divided into filaments, short wire and so on, if the most suitable geotextile should be the project requirements are not very strict , Generally like building coverage, road maintenance, etc., like this price is generally around 0.5 angle

- Q: Pvc tube outsourcing geotextile, how to count how much geotextile

- Calculate the circumference of the bottom of the pipe by the diameter of the pipe, and the length of the pipe is multiplied by the length of the pipe, which is the area of the geotextile. Huazhi geotechnical materials manufacturers to answer your questions

- Q: What are the physical properties of geotextiles?

- Geotextiles are engineered fabrics that possess various physical properties. They are typically lightweight and flexible, allowing for easy handling and installation. Geotextiles also exhibit high tensile strength, enabling them to withstand stress and strains that occur during construction or erosion control applications. These fabrics are permeable, allowing water and gases to pass through while retaining soil particles. Additionally, geotextiles are resistant to UV degradation, chemicals, and biological degradation, ensuring their durability and longevity in outdoor environments.

Send your message to us

Mirafi 160N PP/PET Nonwoven Geotextile with High Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords