MGK Model 5t-1200t Boat Handling Crane,Lifting Equipment,Crane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Profile

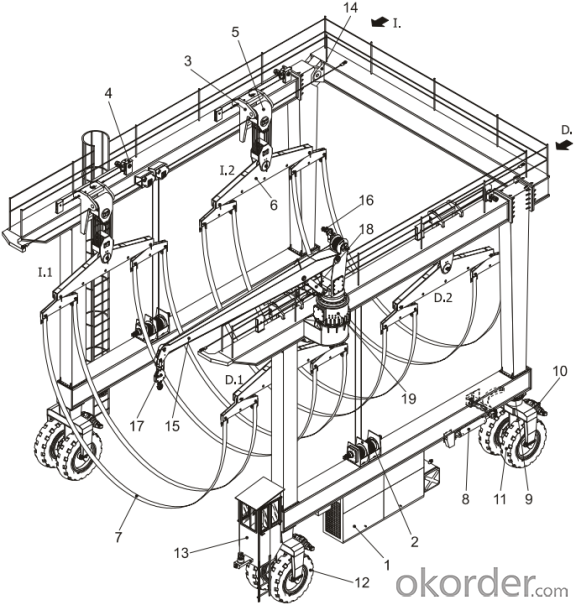

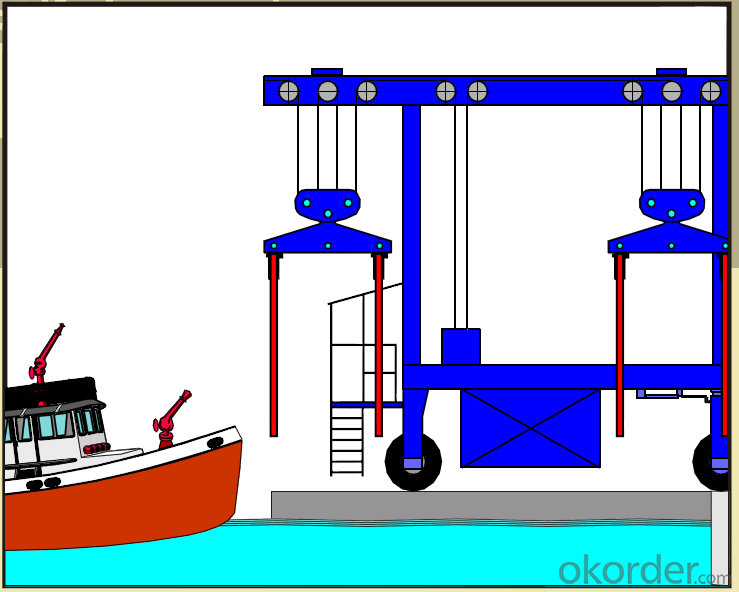

The MGK Model 5t-1200t Boat Handling Crane is designed according to the user's requirements and it used to transport various hulls. In the design, it is fully considered that the hoisted object may exceed the height of the top cross beam, so the "U" shape structure is selected so as to be lifted into the boat handling crane.

This kind of crane can store ships on shore to make it easy to maintain and repair these facilities and reduce the cost of ship maintenance. The MGK Model 5t-1200t Boat Handling Crane is mainly composed of main structure, control system and the following organizations.

1.- Dynamical System 2. Hoisting Mechanism 3.Travelling Trolley

4.- Shifter 5. Upper Sheave Block 6. Lower Sheave Block (Balance Beam)

7. Sling 8. Wheel Steering Mechanism 9.Steering System

10.- Travelling Mechanism 11.- Driving Wheel Group 12.- Driven Wheel Group 13. Cab 14.- Beam Splice

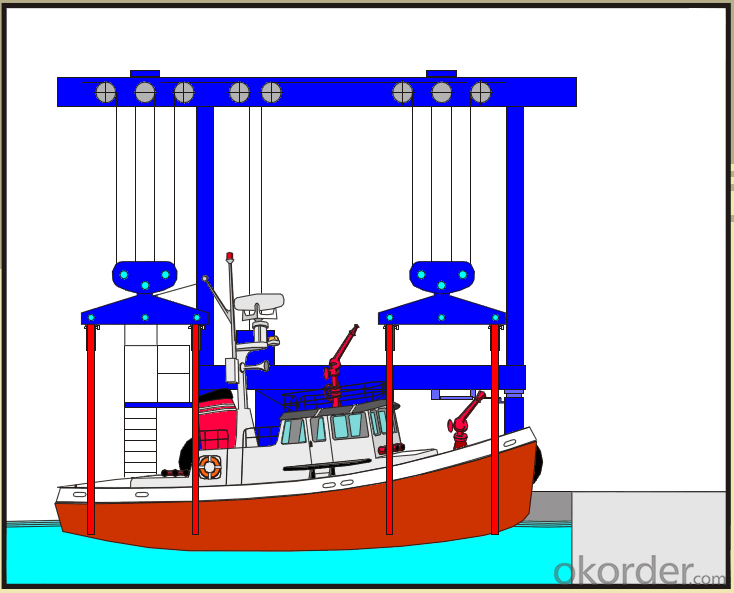

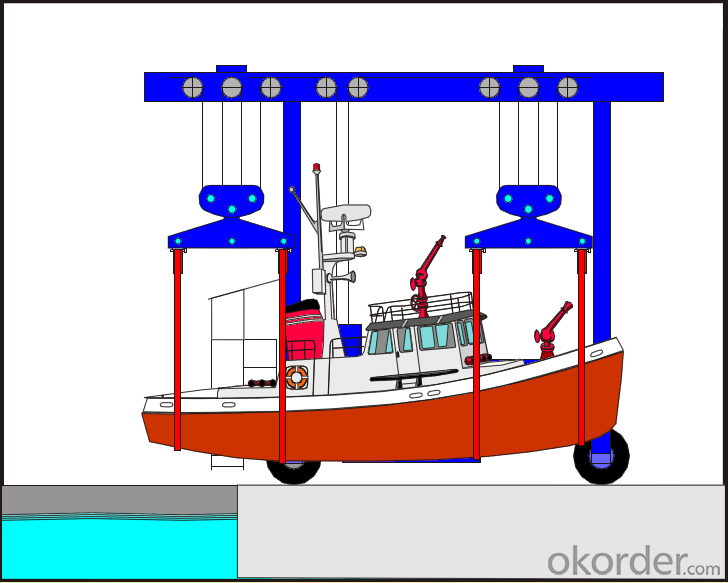

- Operation processing of MGK Model 5t-1200t Boat Handling Crane:

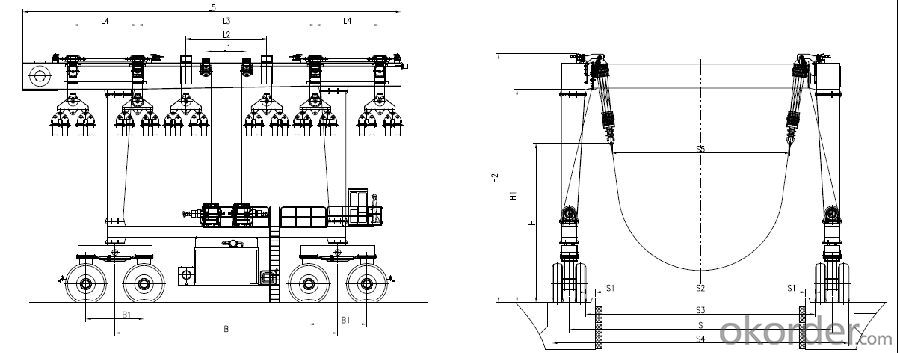

Overall Drawing

Main Structure

The main structure is composed of lower stringer, outrigger, upper stringer and top rail; the lower end of the supporting leg is connected with the lower stringer, and the upper end is connected with the stringer; the upper stringer is connected with the two ends of the top rail respectively to composed of a C-shaped structure.

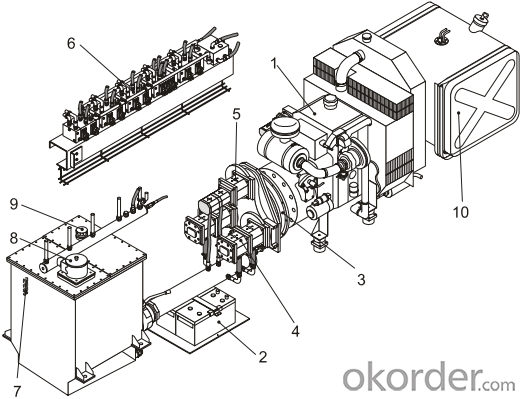

Dynamical System

The dynamical system provides electrical energy for diesel generating sets, and is used for the power consumption of hydraulic systems, control systems and lighting.

The main components are:

1. Diesel engine

2. Battery pack

3. Connecting piece

4. Main pump (Motor / pump)

5. Auxiliary pump

6. Distributor

7. Hydraulic oil container

8. Return oil filter

9 .Air filter

10. Fuel tank

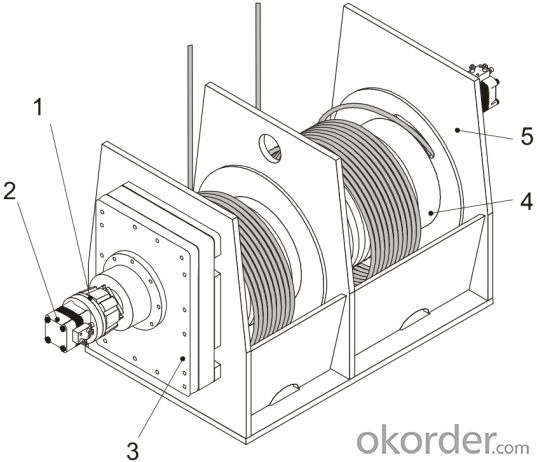

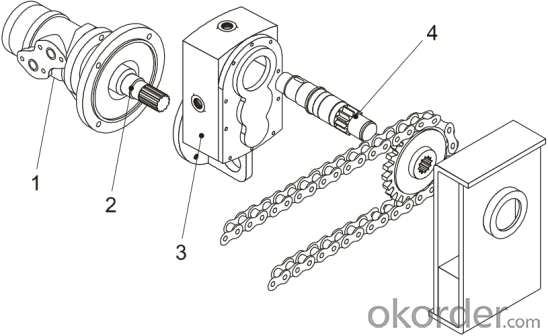

4. Hoisting Mechanism

The hoisting mechanism is composed of hydraulic winch, guide wheel group, fixed pulley block, movable pulley block and sling. The winch is installed on the lower stringer, and the guide wheel set and the fixed pulley block are installed on the upper stringer. The wire rope is connected between the winch, the guide wheel set, the fixed pulley block and the movable pulley block; the corresponding movable pulley block is equipped with a sling for lifting the boat.

The components of hydraulic winch are:

1.Brakes

2.Hydraulic motor

3.Reducer

4.Reel

5.Frame

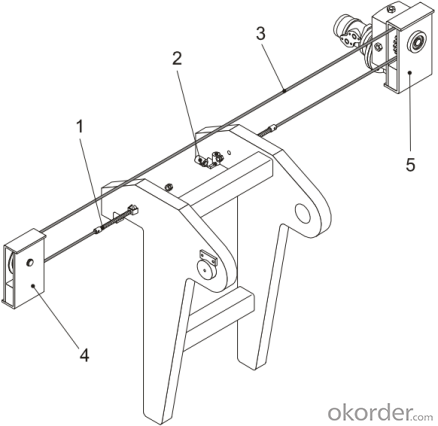

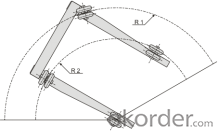

5. Travelling Trolley

Travelling trolley is diagonal structure, the diagonal trolley is placed on the top of the main beam and the side of the sliding track. Chain wheel is arranged at both ends of the top rail of the main beam, and it installed on the main beam what is fixed on both sides of the diagonal trolley. Drive the chain wheel of one end of the main rail to slide through the slider on the main sliding track to make the trolley move horizontal, so as to adjust the the lifting point spacing of the hoisting mechanism.

the top of the main beam and the side of the sliding track. Chain wheel is arranged at both ends of the top rail of the main beam, and it installed on the main beam what is fixed on both sides of the diagonal trolley. Drive the chain wheel of one end of the main rail to slide through the slider on the main sliding track to make the trolley move horizontal, so as to adjust the the lifting point spacing of the hoisting mechanism.

Trolley installation and tensioning device.

Sliding device of trolley on track

Drive chain

Driving device

Hunting gear

Motor

Connector

Gearbox

Sprocket

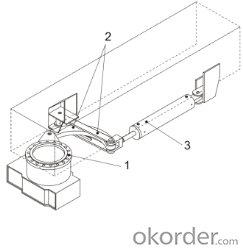

Steering system

The wheel of crane has the function of steering driven by hydraulic system

, which can realize full-steer. The design of it can make it have major maneuverability in a relatively small space

1. Slewing bearing

2. Steering mechanism

3. Hydraulic cylinder

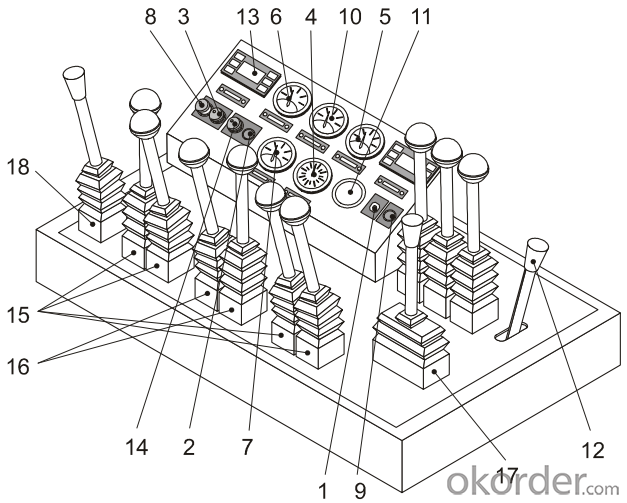

Control system

The control console is set in cab, which contains all kinds of essential instruments, such as monitoring, operation and control buttons. The following parts are the mainly parts:

1. Start button

2. Emergency light(Exterior light) 3.Oscillator

4. Click counter

5. Oil pressure gauge

6. Thermometer of motor

7. Volmeter

8. Heat lamp of starting

9. Horn

10. Indicator of fuel and gas tank

11. Scram button

12. Accelerate rod

13. Display panel of weight(1-3)and(2-4)

14. Speed variator

15. Handling rod of lifting

16 Handling rod of trolley movement

17. Handling rod of long distance movement

18. Handling rod of crane horizontal movement

Considering the requirement of customer, the developed MGK model 5-120t boat handling crane by our company has following advantages

The MGK model 5-120t boat handling crane is made up of main structure, running wheel sets, lifting mechanism, steering mechanism, hydraulic transmission mechanism, electrical control system and other systems. The main structure is type, which can transfer the boat that height is higher than the boat handling crane. The rubber-tyred travelling system has the function of diagnal, 90°steering or steering on site. In line with the requirement, the body of the ship can be placed on the any specified places. It can quickly and flexibly arrange the body of the ship in tow. It can quite shorten the distance among the body of ship, which can save the storage space.

The lifting mechanism, traveling mechanism and horizontal movement adopts electric-hydraulic , transmission system, which has the advantage of stable traveling of transmission device, show quick reflex, small inertia, high-speed starting, braking and steering, small volume, light weight,compact structure, simple and convenient operation, tending automation. It can realize step speed regulation during operation conveniently, which has overload protection.

The lifting mechanism adopts multiple-point lifting. All the lifting points can realize linkage. Also, it can realize separate adjusting, which can dispersion force on the body of the ship, which can realize balanced lifting. The distance among each point can be moved to adjust for satisfying the requirement of different body of ship.

It adopts soft and strong lifting belts to lift the surface of shipper, houseboat or wooden boat uniformly. And it will not damage the surface of the boat at all.

FAQ

Whether if the lifting capacity and boundary dimension of the products can be ordered in according with the requirement of user?

Certainly.

What’s the manufacturer of the hydraulic and electronic component?

Often, it adopts international mega brand, such as Danvers, Rexroth, Brevini, ABB, Siemens and others. Also, it can use the assigned brand by user.

- Q: What is the transport theory in logistics management?

- It is. The moving activity index is used to represent the active parameters of items in various states. Handling process step, should be designed to make the activity of the materials or goods index gradually increase (or at least reduce), which is called the activation step by step. Use active exponent to handling the activity of high and low, handling of active index of high handling method is a better way

- Q: How is the information flow of the material handling system implemented?

- A set of material storage and transportation system that can carry the workpiece and the tool between the workstations of the machine. FMS is a programmable manufacturing system that contains automatic material delivery equipment that enables information integration and logistics with the support of computers...

- Q: Ask for material handling robot design report

- Now to * * * * provided free of charge is the prototype of the robot from the plane, surface, on the steps, or wheels powered by power with the feet, you don't have to like Honda robot behind bear power battery; Of tsinghua university, Dr Robot professional to work in Beijing jiaotong university after manufacture and displayed on the (shenzhen robot also towing power supply cable, and environmental protection, and innovation, also put forward the new method of raider buggies competition; * * * is a display of patriotism, defense, military and science popularization of education. As to surpass foreign flight simulator XunLianCang, can produce a controllable * * * equipment foundation information, has been notified to the * * * *, can be produced in the nearby enterprises, with himself informed, have not seen the similar device. You can also instruct the student to write the invention patent application document (the university intellectual property course and the patent attorney don't teach you!) All this is the hard way to raise ticket prices.

- Q: What is the difference between the requirements check function and the anti-check material list

- The first is the relevance of the material, and any material is always present because of a need; There is no need for materials without requirements. The second is the liquidity of the material, since there is demand, the material always flows from the supply side. The correlation of materials determines the liquidity of the material. Finally, the material is valuable, on the one hand it occupies the capital, in order to accelerate the turnover of funds, the material flow should be accelerated. , on the other hand, in the process of material form and change of flow, with innovation competition () is not only reduce the price competition, improve the technology content and added value of material, with minimal cost, the shortest cycle, best service, to provide customers the best value and bring their own corresponding profits. This is where the value added chain means. Three properties interact and influence each other. Understanding the management characteristics of materials can help to understand the characteristics of material requirements management. Material requirement types in terms of manufacturing, due to the material requirements according to different sources, MRP Ⅱ system divides into the material "independent requirements (independent demand)" and "related requirements (dependent demand)" two kinds big. This is the first of the material requirements planning (MRP) founders, Dr. Joseph a. rlicky, an expert at IBM, in 1965.

- Q: How do you query the serial number of each part of the lenovo notebook

- The packing list contains the material number Or common sense to the lenovo website, you need to provide a host number.

- Q: How is it based on the characteristics of various handling systems

- How are you The various elements of the moving material should be considered in the choice of handling equipment including the moving and method used

- Q: There is no quarterly material transfer label. How do you analyze it in 5

- The horizontal distance from the outside edge of the elevator platform and the unloading platform should not be greater than that

- Q: The horizontal distance from the outside edge of the elevator platform and the unloading platform should not be greater than that

- The high limit mechanism of the material hoist is installed on the shaft of the gearbox and the shaft part of the spline shaft and the shaft part of the shaft, and the CAM is installed on the shaft. With a fork extending to the root of the CAM, the CAM can be applied to the spline shaft, or the shaft part of the shaft. Attach a spring to the CAM, and the other end of the spring is connected to the box

- Q: What kind of equipment is the material handling equipment

- Locate the handling equipment. The equipment is used to process materials in a single position so that they can be processed, processed, transported and stored in the right place. Transport equipment and location devices are typically used for processing in a single workplace. The material can also be used manually with no equipment positioning. The unit load forms the handling equipment. The equipment is used to limit the material so that they maintain their integrity when processing a load on transport and storage. If the material is self-constraining (for example, a single or interlocking portion), then they can form a unit load without the device.

- Q: Why is the material advanced air cold and water cooling in the design of the device

- So, water cooling can be cooled to a lower temperature (and air-cooled ratio), so it will be used in the back. The return water temperature of circulating water should not be too high, otherwise it will scale. If it can achieve cooling, it is preferable to save money and save money

Send your message to us

MGK Model 5t-1200t Boat Handling Crane,Lifting Equipment,Crane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords