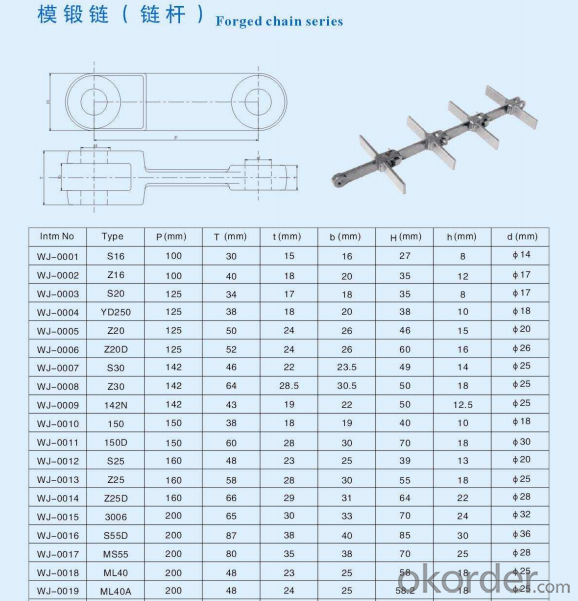

embedded scraper transporter link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

I beam overhead conveyor drop forged scraper chain link

I beam drop forged scraper chain link for overhead conveyor

1.Fine drop forging

2.With or without Zinc plated

F10190 ISO standard 150.0 pitch high tensile drop conveyor forging scraper chain

1.link 15.0mm

2.pitch 120.0mm

- Q: What is the transport theory in logistics management?

- In the process of handling, loading, mobile, neither the goods of the three process usually has emerged as a whole, loading and unloading times the sum of the relationship with the mobile number is 2:1. People place the materials and goods stored state convenient and ease of handling called handling activity, will be convenient to make the loading and unloading, work fewer goods stacking method called high activity index.

- Q: The stability of material lift machine mainly depends on which parts of the material hoist

- It mainly depends on the transmission system and hydraulic braking system or mechanical braking system

- Q: How do you query the serial number of each part of the lenovo notebook

- The serial number of the parts is according to different suppliers, the products of different and different, such as a laptop keyboard is a company production, will take apart the laptop keyboard, generally have his serial number on the back of the keyboard, the serial number of the each component is given by the manufacturer, with notebook assembly plant it doesn't matter

- Q: There is no quarterly material transfer label. How do you analyze it in 5

- According to the operating principle of ERP system, it is planned by a planning control center according to the ERP through BOM. Then on the basis of material requirements planning, according to the supplier purchasing principle as well as a variety of material production stage corresponds to the lead time, determine the supply of raw materials, components and products plan (including transportation plan) to the workshop or process production and order plan (kanban) and supplier send instructions. Its features are: The source is the production plan; The basic data comes from the accurate BOM and the purchase supply plan;

- Q: The horizontal distance from the outside edge of the elevator platform and the unloading platform should not be greater than that

- Material hoist hanging scaffold platform (also called construction lifter lifting cage) and unloading platform construction scaffolding each floor of the mouth or platform, in order to ensure safety construction, two platform where the horizontal spacing should be not greater than 50 mm.

- Q: The parameters of the powder materials transport vehicle

- (12295 Kg) top speed: 12295 (km/h) emission standards: GB3847-2005, GB17691-2005 countries Ⅲ vehicle description: transportation item description: powder coal, density: 0.78 t/m3, the effective volume of tank: 24.88 cubic meters, the shape of tank size (length/diameter) of tank (mm) : 7200/2320, including tanks straight segment length is 6600 mm; When the chassis is 1560mm, the corresponding car is 1440mm, and the rear suspension of the chassis is 1325mm and the corresponding car is 1675mm. Protective materials: Q235 carbon steel, connection mode: left and right side and bottom protection are connected by welding, the back of the protective section size (mm) : 100 * 50 * 5, the back of the protective ground height (mm) : 540.

- Q: What needs to be paid for forklift? How to determine the pros and cons of a forklift?

- The brand used by industries with poor working conditions and heavy workloads can be used as reference objects, and forklifts are good forklifts that can withstand severe environmental tests. The difference between a forklift and a rental car is that taxis are used much larger than the use of a forklift. Just like the amount of private cars can't be compared to taxis. Forklift is used for renting out more of the price and investment time, not quality. Understanding the strength and background of the manufacturer in some areas is more important than understanding a forklift truck on the surface. Unlike cars, the overall quality of each part of a forklift is important, not just the engine

- Q: What kind of equipment is the material handling equipment

- Handling equipment: As the name implies, refers to the production enterprise of some of the small and medium-sized warehouse, port, wharf and other areas such as the space is large, large metastatic used to transport goods and transfer some of the goods warehouse equipment. This includes: diesel forklift, electric forklift, electric truck, electric platform, etc. With these devices, you can maximize human resources, improve efficiency, and reduce operating costs. The popularization of carrying equipment is an inevitable trend, and in the development of the society at high speed, the carrying equipment must have a foothold.

- Q: What are the components of an automated three-dimensional warehouse?

- Integrated warehouse technology is regarded as the center of material storage in the Integrated Manufacturing System (cims-computer Integrated Manufacturing System). Although the system has been observed in the 1980s, there are not many integrated storage systems in our country. The three phases are the basis for the integration of people, equipment and control systems. In the early 1970s, our country began to study the stereoscopic warehouse of the roadway stacker. In 1980, the first automatic three-dimensional warehouse, which was developed by the Beijing institute of mechanical industry automation, was put into operation in Beijing automobile manufacturing plant. Since then, the warehouse has developed rapidly in our country. According to the incomplete statistics, our country has built a three-dimensional warehouse nearly three hundred, of which there are more than 30 fully automatic three-dimensional warehouses. Our country's automatic warehouse technology has realized the integration of other information decision-making system, and is doing the research work of intelligent control and fuzzy control

- Q: What is the difference between the code for the parts code?

- The parts code is "machine parts codename + parts use range codename + parts drawing number" Because materials are more widely included, the material encoding is more complex and more diverse. The types of materials can be roughly divided into raw materials (black, non-ferrous), wool embryo (forging, casting), standard parts, accessories, home-made parts, components, semi-finished and finished products, products including tooling, labor insurance supplies, energy and so on. The coding of materials can be divided into the storage, technical, classification, the material and the standard.

Send your message to us

embedded scraper transporter link

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords