Automatic Auger Filling Machine for powder and granular

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of the Automatic Auger Filling Machine

This Machine is a complete, economical solution to your filling production line requirements.can measuring and filling powder and granular. It consists of the Filling Head, an independent motorized chain conveyor mounted on a sturdy, stable frame base, and all necessary accessories to reliably move and position containers for filling, dispense the required amount of product, then quickly move the filled containers away to other equipment in your line (e.g., cappers, labelers, etc.).it fits more to the fluidic or low-fluidity materials, like milk powder, albumen powder, pharmaceuticals, condiment, solid drink, white sugar, dextrose, coffee, agriculture pesticide, granular additive, and so on.

2. Features

- Lathing auger screw to guarantee the precise filling accuracy

- PLC control and touch screen display

- Servo motor drives screw to guarantee stable performance

- Quick disconnecting hopper could be washed easily without tools

- Can be setting to semi-auto filling by pedal switch or auto filling

- Full stainless steel 304 material

- weight feedback and proportion track to materials, which overcomes difficulties of filling weight changes due to materials’ density change.

- Save 20 sets of formula inside the machine for later use

- Replacing the auger parts, different products ranging from fine powder to granule and different weight can be packed

- Multi language interface

3. Technical parameters

First type-Liner type

| Model | TP-PF-A21 | TP-PF-A22 |

| Control system | PLC & Touch Screen | PLC & Touch Screen |

| Hopper | Quick disconnecting hopper 25L | Quick disconnecting hopper 50L |

| Packing Weight | 10 - 5000g | 10 - 5000g |

| Dosing mode | Directly dosing by auger | Directly dosing by auger |

| Paching accuracy | ≤500g, ≤±1%; >500g,≤±0.5% | ≤500g, ≤±1%; >500g,≤±0.5% |

| Filling speed | 15 - 40 times per minute | 15 - 50 times per minute |

| Air supply | 6 kg/cm² 0.05m³/minute | 6 kg/cm² 0.05m³/minute |

| Power supply | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Total power | 1.6 KW | 1.6 KW |

| Total weight | 300 kg | 300kg |

| Overall Dimensions | 2000*970*2030mm | 2000*970*2300mm |

Second type- Rotary type

| Model | TP-PF-A301 | TP-PF-A302 |

| Hopper volume | 25L | 50L |

| Container size | φ20-100mm; H15-150mm | φ30-160mm; H50-260mm |

| Control system | PLC & Touch screen | PLC & Touch screen |

| Packing weight | 1 - 500g | 10 - 5000g |

| Packing accuracy | ≤100g, ≤±2%; 100-500g,≤±1% | ≤500g, ≤±1%; >500g,≤±0.5% |

| Filling speed | 20-50 bottles per minute | 20-40 bottles per minute |

| Power supply | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Total power | 1.2 KW | 2.3KW |

| Air supply | 6kg/cm² 0.05m³/minute | 6kg/cm² 0.05m³/minute |

| Total weight | 160kg | 260kg |

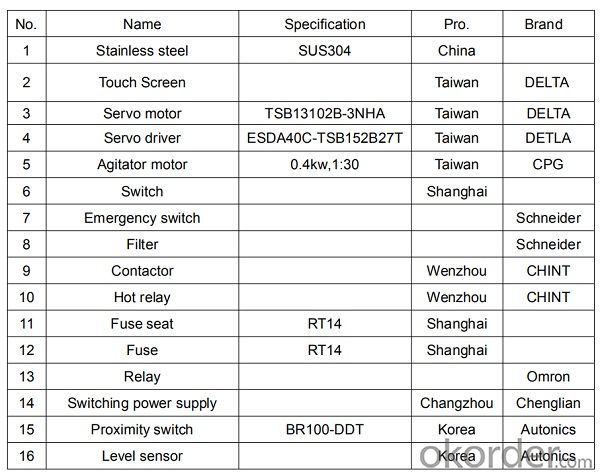

4. Configuration list

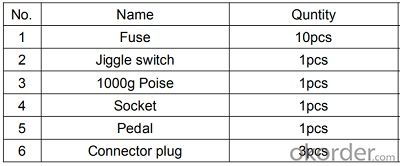

Accessories

Accessories tools

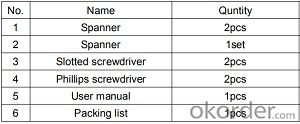

5. Image of fonction

6. Remark

- Delivery Period: 25 days after receipt of down payment

- Payment Terms: 30%T/T as deposit + 70%T/T balance payment before delivery.

- Guarantee Period: 12 months

- Package: seaworthy plywood carton

- Q: What is the transport theory in logistics management?

- Moving company handling the design scheme, main is according to the material classification, distribution and move route, selecting the appropriate combination between handling equipment, equipment and method of use. The active theory of handling and handling can improve the loading and unloading plan, which makes the design of the scheme and the choice of the equipment quantitatively. It also forms an effective method for checking and comparing schemes. Application of the theory of activity, and other conditions and influences, can be achieved.

- Q: The stability of material lift machine mainly depends on which parts of the material hoist

- The cable line should be set when there is no condition to set up the attached wall. Wire rope must be used. (4) anchor force of the anchor, the location of the buried directly influences the effect of cable wind rope, when choosing cable wind rope anchor point, depending on its soil conditions, decided to form and practice of anchor.

- Q: How is the information flow of the material handling system implemented?

- Economic advice is driven by kanban; Make card, participate in TPS Toyota production style pull management method.

- Q: Ask for material handling robot design report

- Now on the college students of the experiment, you block him, at the gate of the laboratory to borrowed his experiment teaching material, were asked about the content of this course, as long as it is accurate, detailed, they not answer, he was dazed, asked the teacher is also a gaping; If he were to make the lab equipment, it would be eight, dead and dead. Now the school teaching equipment is procured from the society, the original manuscript of the experimental handout is provided by the teaching instrument supplier, the other can be imagined. To graduate, is the original abroad under the guidance of scientific literature and database import software systems, hardware platform, market procurement module and application-specific integrated circuit and components of the system integration, fast food science and technology, modern technology large platter

- Q: How do you query the serial number of each part of the lenovo notebook

- Pit of fools, nothing in your accessories, one thousand just change something bad, you find them, set the new pieces will not come, how do they give you handle, I and they often deal with, don't worry, your things within warranty, will give you a new accessories, they have a month in task, finish even fined

- Q: What is the difference between repair cost and machine material

- Repairs usually refers to equipment, parts or parts wear, performance degradation and failure, in order to make the return to original state available to all kinds of repair, adjust, the matter of costs of the corrective actions.

- Q: The horizontal distance from the outside edge of the elevator platform and the unloading platform should not be greater than that

- Material hoist hanging scaffold platform (also called construction lifter lifting cage) and unloading platform construction scaffolding each floor of the mouth or platform, in order to ensure safety construction, two platform where the horizontal spacing should be not greater than 50 mm.

- Q: The parameters of the powder materials transport vehicle

- Tanks using automatic longitudinal welding process, weld formation, tanks use straight-through type or Y type fluidized bed to optimize the external and internal structure of tank, low center of gravity, large volume and other characteristics; The design scientific layout is reasonable, the unloading time is short, the remaining grey rate is low. It is suitable for the transportation and unloading of powder coal ash, cement, lime powder, mineral powder, etc. It is used in double cone, double cone, double pipe inlet and double barrel feed. The material and metal accessories are treated with shotblast, with strong adhesion, good corrosion resistance and uniform paint film, which can withstand all kinds of bad environment. The capacity of the tank is 25 to 40 cubic meters.

- Q: What are the components of an automated three-dimensional warehouse?

- The third stage is the automation of the warehousing technology phase, and the automation technology plays an important role in facilitating warehousing technology and development. In the late 1950s and 60s, automatic pilot car (AVG), automatic shelf, automatic access robot, automatic identification and automatic sorting system were adopted. In the 70 s and 80 s, rotate style shelves, mobile racking, roadway type stacker and other handling equipment joined automatic control, but at this moment is only partial automation of all equipments and application independently, known as the "islands automation". Along with the development of computer technology, the focus turned to material control and management, real-time, coordination and integration, computer, data between patch, mechanical equipment controller and communication between host computer and they can timely summary, warehouse computer record orders in a timely manner and the delivery time, according to inventory, supply planners can easily make a decision, they know what is the production and book what goods, what time to send what goods, management personnel to understand the supply and demand. The application of information technology has become an important pillar of warehouse technology.

- Q: What is the difference between the code for the parts code?

- The parts code is "machine parts codename + parts use range codename + parts drawing number" Because materials are more widely included, the material encoding is more complex and more diverse. The types of materials can be roughly divided into raw materials (black, non-ferrous), wool embryo (forging, casting), standard parts, accessories, home-made parts, components, semi-finished and finished products, products including tooling, labor insurance supplies, energy and so on. The coding of materials can be divided into the storage, technical, classification, the material and the standard.

Send your message to us

Automatic Auger Filling Machine for powder and granular

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches