Melt-extracted Stainless Steel Fiber Used in Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: China

Model Number: 304,310,430,446

Material: Stainless Steel, Stainless Steel

Feature: High quality grade

Standard: ASTM A820

Types: Melt Extracted

Length: 25mm/35mm/19mm

Diameter: 0.3mm-0.7mm

Melting Point: Greater than 1500C

Application: Refractory Industry

Package: In cartons then put into pallets.

Production process:

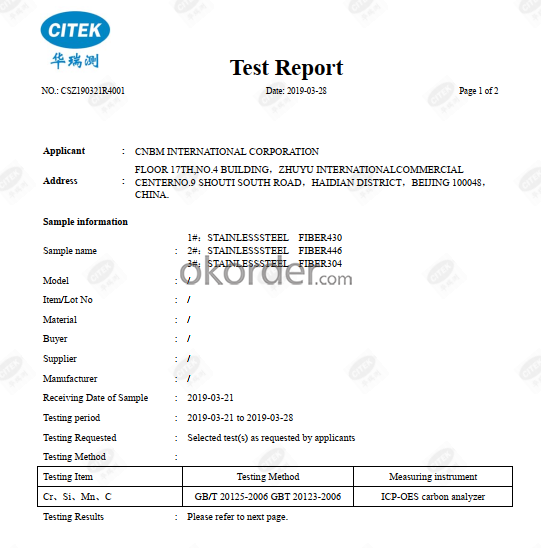

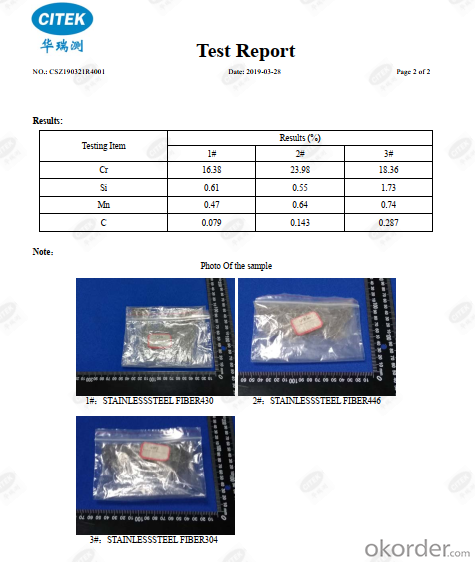

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have other products?

A: Yes, please check the pictures:

Test Report:

- Q: which kind of material is chosen for fireproofing window?

- (1) the inside filler material of steel, wood frame should use incombustible material. (2) window frame uses steel frame or wooden frame with certain strength that can safeguard the integrity and stability of the components. (3) steel frame and mound layer can choose galvanized?steel?sheet or stainless steel plate. Its selection criteria conform to the article 5.1 in GB12955 Steel Fireproof Door General Technical Condition. (4) the selection criteria of wooden frame and mound layer should conform to the article 5.1 in GB12955 Wooden Fireproof Door General Technical Condition. (5) fire-resistant glass can choose test approved products without affecting the fire resistance of fireproofing windows . Light transmittance of glass should not be less than 75% of same layers commom sheet glass. (6) the sealing material between the frame and the fire-resistant glass should use flame retardant materials, it can play a role of fireproofing and smoke insulation in the fire. (7) hardware accessories should be tested qualified approved supporting product.

- Q: What is the role of adding chromium oxide green in unshaped refractory materials

- Generally, less is added in corundum or corundum spinel refractory material, but it can significantly improve the material performance such as high temperature strength, erosion resistance, thermal and shock stability, etc.

- Q: Are the specification of fireclay bricks and ordinary clay brick the same?

- Do you want to know whether the specifications of fireclay bricks and ordinary clay brick are the same?

- Q: What kinds of refractory will be used in kiln of sintering ceramics?

- If it is ordinary ceramic, you can use ordinary clay bricks and high alumina brick, adding calcium silicate board, the insulating brick and cotton fiber.

- Q: Who knows the fire rating of fire?partition with steel stud?

- Partition system made by fire?partition with steel stud and high-quality keel has good fireproofing performance and is non-combustible sheet. Flame burn duration is zero. It does not burn at 800℃, and it is without flame at 1200℃. Its fire resistance rating reaches GB8624-A standard through test, which reaches the highest fireproofing and non-combustible level grade A1. 10MM fire endurance can reach up to 4 hours fire resistance maximum limit. It can absorb a lot of heat during the process of burning and delay the rise of temperature in surrounding environment.

- Q: Is the linear change on reheating the same as heating permanent linear change of refractory material?

- “+”represents expansion. the afterexpansion and aftercontraction after cooled to be at room temperature. The change may significantly damage the masonry of thermal kiln. There are regulations on the linear change on reheating of common refractory material in the national standard. Some physical chemical changes may continue. It is defined as the change from being heated to the specified temperature of refractory material sample. Heat preserving for a while till afte cooling to be at room temperature, then the residual will expand or contract in its length, heat preservation for a while, organization vitrification, the irreversible changes of its length refers to heating the firing refractory to be at high temperature, so as to make the volume of refractory materials expand or contract, due to the influence of uneven temperature or lack of time, otherwise it will cause the deformation of the refractory ball and make this indicator within standard even reach smaller value, so firing control must be strengthened in product production. But it is should not be too high. For refractory materials with same chemical composition, the linear change on reheating is produced in the heating process. Properly increasing sintering temperature and prolonging the holding time is an effective process measures, make its firing inadequate. When subjected to high temperature, it can reduce the thermal shock resistance. Minus sign "-" represents contraction. The permanent line rate refers to heating the fire refractory ball to the specified temperature. Linear change on reheating, also known as residual linear change, is an important indicator to assess the quality of refractory in the long time use. To control the permanent line rate within the standard or reach the minimum value.

- Q: What is high alumina refractory?

- High alumina refractory: High alumina refractory products, with high refractoriness, compressive strength and refractoriness under load, it is used for masonry of a variety of large-scale blast furnaces such as steel furnace, air heating furnace and electric furnace, and for high-temperature parts of thermal equipment like rotary?kilns.

- Q: Can you tell me the classification of fireproof sealing material.

- Inorganic fireproof plugging material includs: organic fireproof plugging material, fire bags, warfare, fire collars, fire belt, fire prevention sealing strip, flexible fire protection coil, fireproof glue and so on. I hope my answer can help you. Thank you!

- Q: The principle of choosing fire-resistant material in Thermal Energy and Power Engineering equipment.

- What thermal equipment? The most simple principle is durable, low cost and with no environmental pollution.

- Q: Who knows the highest temperature the high-temperature refractory coating can resist?

- The fire endurance of high temperature fire resistant coating is 3 hours. The fire endurance of fireproof is to go on fire resistance test of any building component according to the time- temperature standard curve, which is the period of time started from being put on fire and ended when losing support function or integrity has been destroyed or losing fire insulation function, expressed in hours. I hope my answer can help you. Thank you.

Send your message to us

Melt-extracted Stainless Steel Fiber Used in Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords