Melt Extract Stainless Steel Fiber - Straight Type from CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Jiangsu, China (Mainland)

Model Number: HT-ST

Material: Steel

Specifications

Micro steel fiber:

1.Material: low carbon steel wire,copper coated

Diameter:0.2mm --0.25mm

Length: 12mm-14mm

Tensile strength:>2850Mpa

2.Feature:Excellent tensile, bending and shearing strength, resistance against cracking, impact and fatigue.

3.Use:It is widely used for buildings, road surface, bridges, tunnels, airport road surface, water conservancy projects, military engineering, and all kinds of building products.

Specifications

1.Material: low carbon steel wire

2.Diameter: 0.2mm --0.25mm

3.Length: 12mm-14mm

4. ISO 9001 certificated

Hooked steel fiber:

1.Diameter:0.4mm-1.0mm

2.Length: 25mm-60mm

3.Material: low carbon steel wire

4.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

5.Uses: highway road surface,tunnel,building,airport road surface and so on .

Micro steel fiber:

1.Material: low carbon steel wire,copper coated

Diameter:0.2mm --0.25mm

Length: 12mm-14mm

Tensile strength:>2850Mpa

2.Feature:Excellent tensile, bending and shearing strength, resistance against cracking, impact and fatigue.

3.Use:It is widely used for buildings, road surface, bridges, tunnels, airport road surface, water conservancy projects, military engineering, and all kinds of building products.

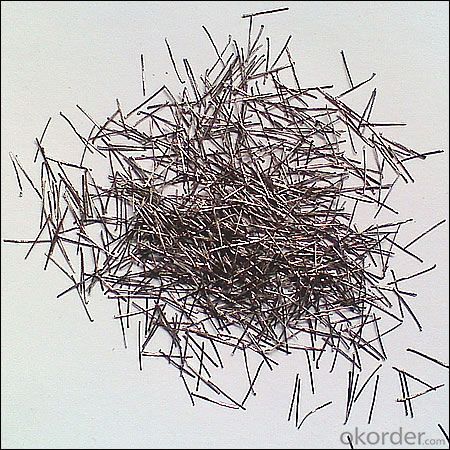

Picture

Steel fiber straight type

FAQ

Straight steel fiber:

1) Material: low carbon steel wire

2) Diameter: 0.4mm

3) Length: 18mm-35mm

4) Tensile strength: >1000Mpa

5) Feature: excellent tensile, high tenacity, against cracking, impact and fatigue

6) Uses: highway road surface, tunnel, building, airport road surface and so on.

- Q: Can melt extract stainless steel fiber be used in tunnel shotcrete lining applications?

- Yes, melt extract stainless steel fiber can be used in tunnel shotcrete lining applications. This type of fiber is known for its high strength, durability, and resistance to corrosion, making it suitable for reinforcing tunnel shotcrete structures.

- Q: What is the tensile strength of melt extract stainless steel fiber?

- Typically, melt extract stainless steel fiber exhibits a tensile strength ranging from 1000 MPa to 2000 MPa. Such a remarkable tensile strength renders it appropriate for diverse applications, including reinforcing concrete, composites, and other structural materials. However, it is important to note that the precise tensile strength may differ depending on the specific grade and manufacturing process employed in the production of the stainless steel fiber.

- Q: What is the effect of melt extract stainless steel fiber on the spalling resistance of concrete?

- The use of melt extract stainless steel fiber in concrete can significantly enhance its spalling resistance. Stainless steel fibers are added to concrete to improve its mechanical properties, including tensile strength, toughness, and ductility. These fibers act as reinforcement and help to distribute the applied stress more uniformly throughout the concrete matrix. When subjected to high temperatures, such as during a fire, concrete undergoes thermal expansion, which can lead to spalling. Spalling occurs when the concrete surface breaks off in fragments due to the rapid release of steam from the heating of entrapped water within the matrix. The addition of melt extract stainless steel fibers in concrete forms a three-dimensional network that helps to restrain the thermal expansion and prevent the propagation of cracks. The fibers act as reinforcement, bridging the cracks and maintaining the structural integrity of the concrete. The stainless steel fibers also have high thermal conductivity, which allows for the efficient transfer of heat away from the concrete surface. This helps to reduce the temperature gradient within the concrete, minimizing the thermal stresses that can lead to spalling. Furthermore, the corrosion resistance of stainless steel fibers ensures their long-term durability in concrete, even in harsh environments. This durability ensures that the spalling resistance of the concrete remains intact over an extended period. In conclusion, the addition of melt extract stainless steel fibers in concrete significantly improves its spalling resistance by enhancing its mechanical properties, restraining thermal expansion, reducing temperature gradients, and providing long-term durability. This makes it an effective solution for applications where fire resistance and structural integrity are crucial, such as in tunnels, parking garages, and high-rise buildings.

- Q: Is melt extract stainless steel fiber compatible with different types of fiber-reinforced polymers?

- Yes, melt extract stainless steel fiber is compatible with different types of fiber-reinforced polymers.

- Q: Can melt extract stainless steel fiber be used in foundation slabs?

- Yes, melt extract stainless steel fiber can be used in foundation slabs. These fibers provide reinforcement and improve the overall strength and durability of the slab. They help to reduce cracking and increase the load-bearing capacity of the foundation, making it a suitable choice for construction projects.

- Q: Is melt extract stainless steel fiber compatible with various types of cement?

- Yes, melt extract stainless steel fiber is compatible with various types of cement.

- Q: Can melt extract stainless steel fiber be used in the construction of railway tunnels?

- Yes, melt extract stainless steel fiber can be used in the construction of railway tunnels. Stainless steel fiber is known for its high strength, durability, and resistance to corrosion, which makes it suitable for various construction applications, including railway tunnels. The use of stainless steel fiber in tunnel construction helps to enhance the overall structural integrity and longevity of the tunnels. It can reinforce the concrete used in the tunnel lining, providing increased resistance to cracking and improved load-bearing capacity. Additionally, stainless steel fibers can also offer enhanced fire resistance properties, which is crucial for ensuring the safety of railway tunnels. Therefore, melt extract stainless steel fiber is a suitable material to be used in the construction of railway tunnels.

- Q: What is the effect of melt extract stainless steel fiber on the freeze-thaw resistance of concrete?

- The addition of melt extract stainless steel fiber to concrete enhances its freeze-thaw resistance. The fibers help to reduce cracking and improve the overall durability of the concrete by providing reinforcement and preventing moisture penetration. This results in increased resistance to freeze-thaw cycles, where the repeated expansion and contraction of water within the concrete can cause damage.

- Q: How does melt extract stainless steel fiber prevent plastic shrinkage cracking in concrete?

- Melt extract stainless steel fiber is a type of reinforcement material that is commonly used in concrete to prevent plastic shrinkage cracking. Plastic shrinkage cracking occurs when the concrete surface dries out too quickly, causing it to shrink and crack before it has fully hardened. The stainless steel fibers are added to the concrete mix during the mixing process. These fibers are extremely thin and have a high tensile strength, which means they can withstand high stress without breaking. When the concrete starts to dry and shrink, the stainless steel fibers distribute the stress evenly throughout the concrete matrix, preventing the formation of large cracks. The presence of these fibers also helps to reduce the overall drying shrinkage of the concrete. This is because the fibers create a network within the concrete that holds it together and limits the movement of the individual particles. As a result, the concrete experiences less shrinkage as it dries, reducing the likelihood of cracking. Additionally, the stainless steel fibers also improve the overall durability and toughness of the concrete. They enhance the resistance to impact, abrasion, and cracking, making the concrete more resilient and long-lasting. Overall, melt extract stainless steel fiber plays a crucial role in preventing plastic shrinkage cracking in concrete by providing reinforcement and reducing the overall shrinkage of the material. Its addition to concrete mixes helps to ensure that the concrete surface remains intact and structurally sound, even during the early stages of drying and hardening.

- Q: What is the effect of melt extract stainless steel fiber on the flexural toughness of shotcrete?

- The effect of melt extract stainless steel fiber on the flexural toughness of shotcrete is an increase in the overall toughness and crack resistance of the material. The stainless steel fibers reinforce the shotcrete, preventing the propagation of cracks and enhancing its ability to withstand bending and flexural stresses. This results in improved durability and structural integrity of the shotcrete, making it more suitable for applications where flexural toughness is important, such as tunnel linings or retaining walls.

Send your message to us

Melt Extract Stainless Steel Fiber - Straight Type from CNBM International China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 30000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords