Melt Extract Stainless Steel Fiber Reinforced Wavy Shear-Cut Concrete Admixtures

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Shandong, China (Mainland)

Model Number: steel fiber

material: steel wire

application: concrete reinocement

type: end hook steel fiber

Product features

Steel band shearing type steel fiber

Good quality, low price, high cost performance

Product overview

1, through the ISO9001 certification

More than

2, Material: low carbon steel strip

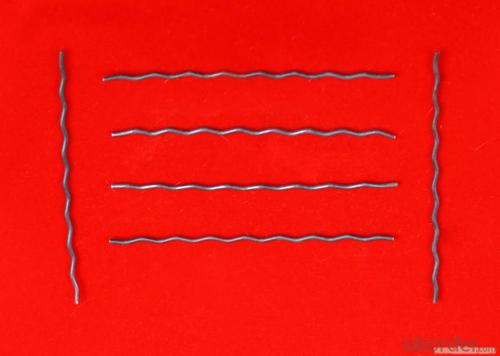

3. Shape: Wave

4. Multi anchorage points, rolling force is good

5. good quality, low price, high cost performance

wavy steel fiber

1, the length of 15 - 50 mm

2, the diameter of 0.5-1.2 mm

3, the intensity is 380-600 mpa

Specifications

1.hooked steel fiber

2.CE and ISO9001:2008

3.diameter from 0.5mm to 1.2mm

4.competitive price,high quality and service

Hooked Steel Fiber:

1.Diameter:0.5mm-1.0mm

2.Length: 25mm-60mm

3.Material: low carbon steel wire

4.Feature: excellent tensile,high tenacity,against cracking,impact and fatigue

5.Uses: high way,tunnel,building,airport road serface and so on .

Picture

steel fiber concrete reinforced

FAQ

we can produce any type steel fiber and of course we can make production according to your requirement

we have specilize in this field for almost 10 years ,with good quality and competitive price

- Q: Can melt extract stainless steel fiber be used in the construction of tunnels?

- Yes, melt extract stainless steel fiber can be used in the construction of tunnels. It is commonly used as a reinforcement material in tunnel construction due to its high tensile strength, durability, and resistance to corrosion. The fibers are added to the concrete mix to enhance its structural integrity, prevent cracking, and increase overall durability of the tunnel.

- Q: How does melt extract stainless steel fiber affect the rebound of shotcrete?

- Melt extract stainless steel fiber improves the rebound of shotcrete by enhancing the bond between the concrete and the substrate. The fibers act as reinforcement, reducing cracking and increasing the overall strength of the shotcrete. This results in less rebound, as the shotcrete adheres better to the surface and has improved workability.

- Q: How does melt extract stainless steel fiber improve the impact resistance of concrete pavers?

- Concrete pavers' impact resistance is greatly improved by the unique properties and characteristics of melt extract stainless steel fiber. These fibers, when added to the concrete mix, act as reinforcing elements, enhancing the toughness and durability of the pavers. The main factor behind this improved impact resistance lies in the high tensile strength of stainless steel fibers. These fibers are manufactured using a melt extraction process, ensuring a consistent and uniform distribution throughout the concrete matrix. This distribution effectively disperses the stress caused by impacts, preventing the concentration of forces on specific areas of the pavers. Furthermore, the stainless steel fibers also bolster the flexural strength of the concrete pavers. This means that the pavers can endure bending forces resulting from impacts without cracking or breaking. The fibers form a reinforcement network, strengthening the cementitious matrix and halting the spread of cracks. Apart from the increased strength, stainless steel fibers also enhance the overall durability of concrete pavers. The stainless steel material boasts exceptional corrosion resistance, making it particularly advantageous in outdoor or high-moisture environments. This resistance ensures that the fibers retain their strength and integrity over time, further boosting the pavers' impact resistance. In summary, melt extract stainless steel fiber significantly enhances the impact resistance of concrete pavers by providing superior tensile strength, flexural strength, and durability. By incorporating these fibers into the concrete mix, pavers are capable of withstanding heavy loads, impacts, and other external forces without compromising their structural integrity.

- Q: How does melt extract stainless steel fiber contribute to the ductility of concrete?

- Melt extract stainless steel fibers contribute to the ductility of concrete in several ways. Firstly, these fibers are added to the concrete mixture in small proportions, which enhances the overall flexural and tensile strength of the concrete. This results in a more ductile material that can withstand greater loads and resist cracking. Secondly, the unique properties of stainless steel, such as high tensile strength and corrosion resistance, make it an ideal material for reinforcing concrete. When added as fibers, the stainless steel provides additional reinforcement throughout the concrete matrix, increasing its overall toughness and ductility. Furthermore, the randomly dispersed stainless steel fibers act as micro-crack arrester, preventing the propagation of cracks and enhancing the post-cracking behavior of the concrete. This means that even if cracks do occur, they are less likely to propagate and lead to catastrophic failure. In addition, the melt extract stainless steel fibers improve the bond between the concrete matrix and the fibers themselves. This improved bond allows for more effective load transfer between the fibers and the surrounding concrete, further enhancing the ductility of the material. Overall, melt extract stainless steel fibers contribute to the ductility of concrete by improving its flexural and tensile strength, enhancing crack resistance, and improving the bond between the fibers and the concrete matrix. This results in a more durable and resilient material that can withstand greater loads and deformation without failure.

- Q: What is the effect of melt extract stainless steel fiber on the thermal conductivity of concrete?

- The inclusion of melt extract stainless steel fiber in concrete tends to enhance its thermal conductivity. The fibers act as heat conductors within the concrete matrix, facilitating the transfer of heat throughout the material. This results in improved thermal conductivity and better heat distribution within the concrete structure.

- Q: Can melt extract stainless steel fiber be used in combination with other types of reinforcement?

- Yes, melt extract stainless steel fiber can be used in combination with other types of reinforcement in various applications. It can be combined with materials like concrete, polymers, or composites to enhance their mechanical properties, such as improved tensile strength, crack resistance, and durability. The addition of stainless steel fibers can provide synergistic effects and improve the overall performance of the reinforced material.

- Q: How does the addition of melt extract stainless steel fiber affect the ductility of concrete?

- The addition of melt extract stainless steel fiber generally enhances the ductility of concrete. Stainless steel fibers are known for their high tensile strength and excellent corrosion resistance. When added to concrete, they help to bridge cracks and improve the overall flexural performance of the material. Concrete is a brittle material that tends to crack under tensile stress. These cracks can propagate and ultimately lead to failure. However, by incorporating stainless steel fibers, the concrete's ability to withstand tensile forces is greatly improved. The fibers act as reinforcement, increasing the material's resistance to cracking and improving its overall ductility. The presence of stainless steel fibers in concrete also helps to distribute stress more evenly throughout the matrix. This prevents the concentration of stress at specific points, making the material less prone to brittle failure. As a result, the concrete becomes more flexible, allowing it to absorb more energy before reaching its breaking point. Additionally, stainless steel fibers can help to reduce shrinkage and minimize the formation of plastic shrinkage cracks in concrete. This is particularly beneficial in situations where the concrete is subjected to drying conditions or temperature fluctuations. Overall, the addition of melt extract stainless steel fiber to concrete positively affects its ductility by improving its crack resistance, enhancing its flexural performance, and increasing its energy absorption capacity.

- Q: Can melt extract stainless steel fiber be used in precast tunnel invert segments?

- Yes, melt extract stainless steel fiber can be used in precast tunnel invert segments. These fibers are often added to concrete mixes to improve its strength, durability, and resistance to cracking. In the case of precast tunnel invert segments, incorporating melt extract stainless steel fibers can enhance the overall structural integrity of the segments, making them better equipped to withstand the harsh conditions and loading requirements of a tunnel environment.

- Q: Does melt extract stainless steel fiber improve the fatigue resistance of concrete?

- Concrete can be improved in terms of fatigue resistance by adding melt extract stainless steel fiber. These fibers are known for their high tensile strength and excellent corrosion resistance. When incorporated into concrete, they serve as reinforcement and help distribute stress more evenly, reducing the chances of cracking and failure under cyclic loading conditions. The inclusion of melt extract stainless steel fiber in concrete significantly boosts its ability to withstand fatigue. These fibers absorb and dissipate energy during loading and unloading cycles, reducing the accumulation of microcracks and increasing the overall durability of the concrete. This enhanced fatigue resistance is particularly advantageous for structures subjected to repetitive or dynamic loading, such as bridges, pavements, and industrial floors. Moreover, melt extract stainless steel fibers possess a high aspect ratio, meaning they have a relatively long length compared to their diameter. This characteristic allows the fibers to effectively bridge cracks that may occur in the concrete, preventing their propagation and enhancing the structural integrity of the material as a whole. In conclusion, the addition of melt extract stainless steel fiber greatly enhances the fatigue resistance of concrete, making it more capable of withstanding cyclic loading. This reinforcement prevents the formation and spread of cracks, resulting in a more durable and long-lasting concrete structure.

- Q: Can melt extract stainless steel fiber be used in nuclear power plant applications?

- Indeed, melt extract stainless steel fiber finds utility in nuclear power plant applications. Its exceptional corrosion resistance, high temperature tolerance, and commendable mechanical properties render it suitable for an array of pivotal roles within these plants. These roles encompass reinforcing concrete structures, augmenting the thermal and mechanical attributes of concrete, and fortifying the overall structural integrity of the facility. Moreover, the employment of stainless steel fibers bolsters the resistance to radiation damage, a pivotal requirement in the nuclear power plant setting. Thus, melt extract stainless steel fiber emerges as a dependable and efficient material for utilization in nuclear power plant applications.

Send your message to us

Melt Extract Stainless Steel Fiber Reinforced Wavy Shear-Cut Concrete Admixtures

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 kg

- Supply Capability:

- 250000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords