Homedepot Plywood Melamine Sheets Particle Board Chipboard

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

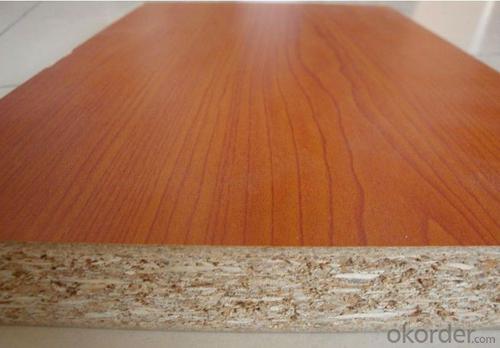

1220x2440x16mm melamine particle board/chipboard

Size:4x8,5x8,6x8,6x9

Thickness:3~30mm

Color:any color

Certificate:ISO9001

Description

| Product Description | melamine laminated coated weight of particle board |

| Glue | E1, E0, E2 |

| Material | particle board |

| Density | 782kg/m3 |

| Size | 1220*2440*150mm |

| Thickness | 12,15,16,18,24.5,25mm |

| Surface | Double Sanding |

| Density Warp | 8.00% |

| Moisture Content | 4-6.6% |

| Expansion ratio | 8.0-9.6% |

| Internal Bond Strength | ≥0.29-0.34MPa |

| Bending Strength (Modulus of Rupture) | ≥2780MPa |

| Certification | ISO9001:2000,CARB (SGS) |

| Packing | 1. Bulk package/loose package. 2. Export packing |

| Place of Origin | Foshan, Guangdong, China |

| Brand Name | LinHao |

Features:

1. Smooth surface , high gloss, scratch resistant and UV stabilized resistant.

2. Fireproof, environmentally-friendly, moisture-proof.

3. Corrosion resistance, economical, stylish and durable etc.

4. High bending strength and easy to work.

5. Surface comparable to gloss /mirror finish.

FAQ:

1.Sampling:

We kindly understand an order intention is outlined with a sample order request. Therefore, we welcome customers to initiate a business opportunity by giving us a sample order as a trial of our quality and service. We are confident you will be positively impressed with our professionalism, quality and service.

2.Sample Lead Time:

Sample Lead Time: 3-7 working days

Production Lead Time: 15-20 days after received the deposit

3.Sample Fee:

Free sample available with freight collect

Production Line:

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- partition panel, the board formed by drilling a variety of patterns, the surface spraying a variety of coatings, decorative effect is better

- Q: Selection of plywood in plywood production

- Artificial veneer is the use of relatively low prices of logs cut into veneer, made by a certain process pressure made of wood, and then cut into a beautiful pattern decorated veneer.

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- the difference between the process: multi-layer solid wood flooring will be a layer of each layer of scientific criss-cross, to eliminate internal stress, at present, its layers have grown from 7 to 9 layers, 11 layers

- Q: The Decorative veneer veneer plywood grade classification

- China veneer veneer veneer plywood standard veneer veneer plywood is divided into excellent products, first-class goods and qualified three grades

- Q: What are the processing defects of plywood?

- Warping warPing is generally a regular deformation, part or all of the surface of the plywood is curved.

- Q: What are the defects in plywood material?

- holes In the process of shipment, holes are caused by hooks and tools for workers' picking.

- Q: Ordinary plywood is divided into four categories

- Thickness specifications for the 6,9,12,15,18 and so on. The main performance indicators for the water content of 4 to 13%, the expansion of water thickness ≤ 12%, as well as tensile strength, bending strength, grip nail force.

- Q: Plywood in the decoration works how to use

- . With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: Class III resistant tide plywood class IV tonic resistant plywood

- and the dashboard and the inner panel are arranged symmetrically on both sides of the center layer or the core.

Send your message to us

Homedepot Plywood Melamine Sheets Particle Board Chipboard

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 100000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords