Chesapeake Plywood Subfloor & Underlay

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1x40' FCL m³

- Supply Capability:

- 20000M3 Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information of Subfloor & Underlay

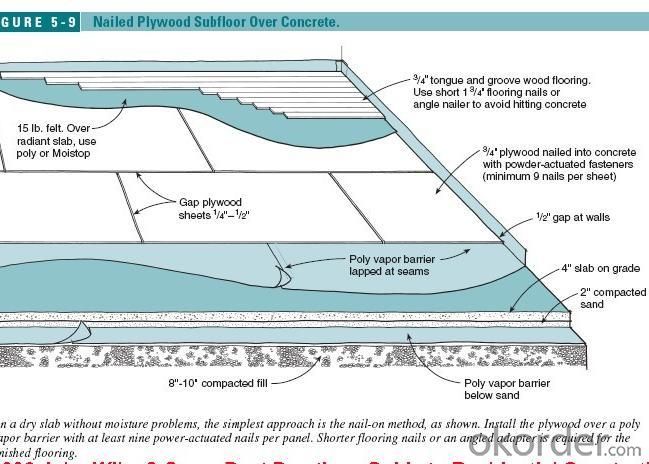

which is used as one layer of base below flooring that requested with an ability to moisture proof and strong enough.

Another request is that it should be economic. For face veneer with putty is allowed by many of customers

Specifications Of Subfloor & Underlay

1.size 1220x2440,1225x2550mm,or as requested2.core Poplar,pine, hardwood F/B Pine

3.grade BB/BB,BB/CC,CC/CC

4.thickness 3-21mm

5.glue MR,WBP,E0,E1,E2 treatment one or two times hot pressed ,sanding or not packing pallet packing or loose packing

6. addition interior application as furniture, roofing panel, underlayment , subfloor; for exterior application as building materials, fences, signs and so on .

PLYWOOD GRADES

Interior Grade Face Back Inner Plies Common Uses

A-A A A D Cabinet doors, built-ins, and furniture where both sides show.

A-B A B D Alternate for A-A. Face is finish grade; back is solid and smooth.

A-D A D D Finish grade face for paneling, built-ins, and backing.

B-D B D D Utility grade. One paintable side. Used for backing, cabinet sides, etc.

C-D C D D Sheathing and structural uses such as temporary enclosures, subfloor. Unsanded.

Underlayment C-plugged D C,D For underlayment or combination subfloor-underlayment under tile and carpeting.

Exterior Grade Face Back Inner Plies Common Uses

A-A A A C Outdoors, where appearance of both sides is important.

A-B A B C Alternate for A-A, where appearance of one side is less important. Face is finish grade.

A-C A C C Soffits, fences, base for coatings.

B-C B C C For utility uses such as farm buildings, some kinds of fences, base for coatings.

C-C plugged C-plugged C C Excellent base for tile, backing for wallcoverings, high-performance coatings.

C-C C C C Unsanded, for backing and rough construction exposed to weather.

- Q: What is the general use of plywood in decoration works?

- Plywood is cut from the wood section into a veneer or cut from the wooden square cut into thin wood, and then made of adhesive glue from the three or more layers of plate-like material

- Q: The difference between the multilayer board and the plywood is as follows

- Also available for aircraft, ships, trains, cars, construction and packaging board and other materials.

- Q: How do I determine if plywood contains formaldehyde?

- Those who claim real real wood furniture, which often possession of plywood.

- Q: How is the current market outlook for plywood?

- A total of 4,732,364 thousand yuan, an increase of 70.26% over the same period last year.

- Q: What are the processing defects of plywood?

- Edge defects at the edges of the panel due to sanding, sawing or collision caused by the corner defects.

- Q: What is a joinery board?

- Blockboard thickness specifications for the 16,19,22,25 mm quality grade is divided into one, two, three three levels

- Q: What are the advantages and disadvantages of plywood?

- the construction is convenient, not Qu Qiao, stripes tensile mechanical properties. light weight, clear lines, insulation, strength, not easy to deformation.

- Q: For the plywood environmental advice?

- Phenolic glue: moisture, excellent resistance to boiling, weather resistance / can be used for outdoor or indoor, can withstand outdoor wind and rain.

- Q: What are the plywood specifications?

- International Organization for Standardization of ordinary plywood production, from the structure, finished product moisture content, quality 3 to make the provisions:

- Q: The usual length and width specifications are:

- Solid wood refers to pure solid wood, that is, all materials are not re-processed natural materials, do not use any furniture made of wood furniture.

Send your message to us

Chesapeake Plywood Subfloor & Underlay

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1x40' FCL m³

- Supply Capability:

- 20000M3 Per Month m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords