Medium Voltage Drive VFD 1100KW 3.3 KV HIVERT-Y 3.3/243

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

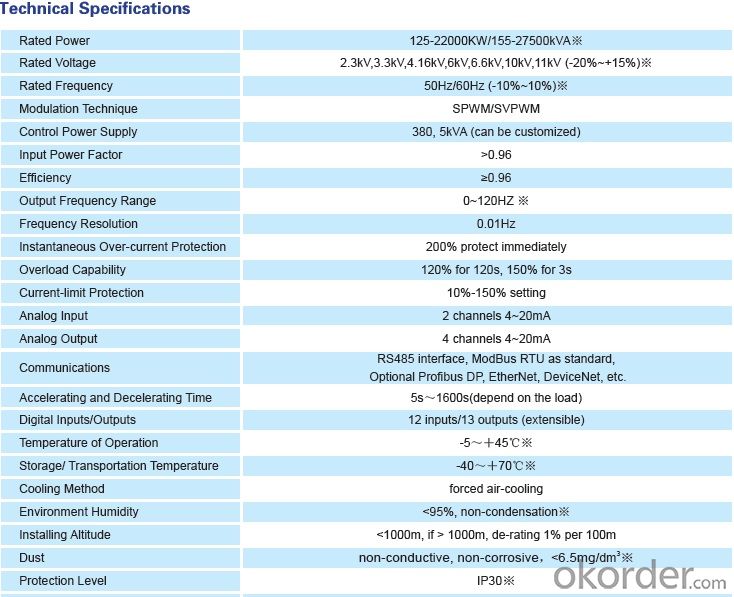

Perfect Power Output Section

The HIVERT general MV VFD adopts the power cells connected in series and voltage overlapping method (i.e. Power cells multi-level cascade technology), it can output the perfect PWM sinusoidal waveform (see Figure 2 and Figure 3). It has the following advantages:

1. No need for the additional output filter

2. Directly driving general synchronous or asynchronous motor

3. No de-rating operation on the motor

4. No dV/dt stress on the insulation of motor and cables

5. No torque ripple, extending service life of motors and mechanism

6. No cable length restriction within the acceptable voltage drop.

The general MV VFD has the following protection functions and features:

Overload and over-current

Phase loss and grounding

Over voltage

Overheat

Current limit

Redundant control power supply

Cell Bypass (optional)

Cabinet door alarm

Phase-Lock function

Synchronous Switching between VFD and Grid system

Soft start of motor

High efficiency >98% (VFD at full-load)

Electrical Isolation by the optic fiber

Built-in PID regulator

RS485 communication with the protocol, Modbus as standard, optional Profibus-DP, Ethernet,etc

Accurate fault records, easy to check fault history

Compact structure and layout, customized design is available

- Q: 380V motor addition to the inverter, but also how to change its speed?

- 1. Change the number of pole pairs of the motor. (Multi-pole motor use) 2. Use the frequency converter to change the frequency

- Q: How is the notebook with a power adapter?

- The safest option is to choose the same type of notebook power adapter. When in some cases (the original adapter is too expensive or not available), you can select the operating parameters and output connectors and the original adapter.

- Q: Is the inverter output current proportional to the output torque?

- When 50HZ or more, the voltage is not increased, the magnetic flux decreases. P = T * n / 9550, if the motor output torque does not change, the current will increase, the motor heat overload

- Q: Three-phase motor, quadrupole asynchronous motor to 15rpm, the inverter output how many volt voltage? The 4 V

- 4 volts too little, at least tens of volts

- Q: Which machines are used for the frequency converter

- Used on a motor that needs to change the speed to change the power.

- Q: The motor is 2 pole with the inverter frequency to 50hz why the speed is only 1500 rpm

- The speed displayed on the display may be the speed of the deceleration or transmission. It is also possible that your inverter parameter ratio is not set, you need to modify and adjust, you want to help.

- Q: What is the meaning of the bipolar polarity in the inverter ah There is a +10V signal input is a -10V What is the meaning of ah?

- Analog signal input: Reference setting Input voltage Positive terminal (0 --- 10V)

- Q: 55 瓩 4 pole motor with a frequency of one hour can save much electricity

- It depends on what type of equipment you use, the average energy-saving fan pumps, about 25-40 between; generic class is based on the frequency you use to decide, according to the frequency you use with 50 Hz Compared to energy saving.

- Q: B2b frequency how to speed

- How does changing the power frequency to change the speed of the motor? When the motor is connected to the power supply to drive the normal operation of the load, at this time to change the power frequency, such as the current frequency down, the motor armature rotating magnetic field speed will decline, the rotor conductor cutting magnetic field speed decreases, turn from the induced potential , The rotor current decreases, the torque decreases, the load on the shaft does not change, the torque will be less than the load resistance torque, the motor rotor speed decreases, the rotor conductor cutting the magnetic field line speed increases, the rotor induced potential increases, the rotor current increases, The torque rises until it is equal to the load resistance torque, and the speed is smaller than the original. After stabilizing the work, the torque of the motor is the same as that of the original. (The motor torque is the same as the load torque, the load is constant and the motor torque is not changed)

- Q: Is the laptop power adapter hot?

- Third, the power of the nominal voltage than my books the battery voltage is much higher, not an accident, right? First of all, to know is that the power supply to the books and the battery power supply to the notebook is different. Battery-powered, the battery output is pure DC, very clean, the battery voltage is neither possible nor need to design a high, lithium battery chemical properties determine a cell output voltage can only be about 3.6V, so Many batteries are used in three cascade way, 10.8V also became a very popular battery voltage. Some batteries are slightly larger than the integer value of 3.6V, such as 3.7V or 11.2V, etc., in fact, to protect the battery. Power supply, the situation is more complex, first of all need to add voltage to further regulation filter to ensure that the power performance is not very good in the case of stable work, the voltage regulator after the two parts of the city, all the way to the work of the power supply , The other way to the battery charge to the part of the power supply to the battery when the same power supply, and the part of the battery charge through the battery charge control circuit can be added to the battery, the control circuit can be very complex, so the power The voltage must be greater than the cell voltage to have sufficient capacity to supply the charge control circuit to the units. Finally the voltage actually added to the cell will never be the nominal voltage of your power supply. Rest assured.

Send your message to us

Medium Voltage Drive VFD 1100KW 3.3 KV HIVERT-Y 3.3/243

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords