Ace EZ Start Masking Tape of Low Tack in Various Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Masking Tape of Low Tack in Various Colors

Interior paint masking, silk screening, Light duty packaging, bundling, holding, splicing &Tabbing, and other non-critical applications where a pressure-sensitive tape is needed.

Size of Masking Tape of Low Tack in Various Colors

Paper Core ID: 76mm

Jumbo size: 0.99m x 1800m, 1.22m x 1800m, 1.51m x 1800m

Cut roll size: As per customer's requirement

Cut rolls: Shrink package, placed in cartons, with or without pallet

Packing of Masking Tape of Low Tack in Various Colors

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

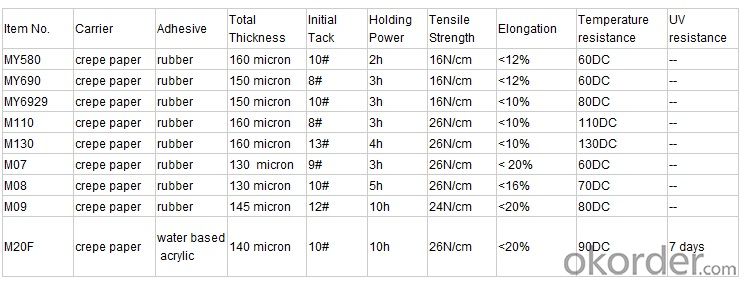

Technical Data of Masking Tape of Low Tack in Various Colors

Picture Show of Masking Tape of Low Tack in Various Colors

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s world wide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferencial shipping channels, with a separate team dealing with shipping.

- Q: What is the difference between acrylic and hot melt adhesive for packaging tape?

- Packaging tape commonly utilizes two types of adhesives: acrylic and hot melt. These adhesives possess distinct characteristics that set them apart. A significant disparity lies in their bonding strength. Hot melt adhesive boasts exceptional bonding strength, making it ideal for heavy-duty applications. It creates a robust and durable bond that can withstand rigorous handling and varying temperatures. Conversely, acrylic adhesive typically offers a lower level of bonding strength in comparison. While still suitable for most general packaging requirements, it may not be the best choice for heavy or bulky items. Another distinction can be found in the application process. Hot melt adhesive is applied in a molten state and solidifies once cooled. Typically, it is dispensed using a hot melt glue gun or applicator. The quick setting time of hot melt adhesive allows for swift packaging operations, making it popular in high-volume settings. On the other hand, acrylic adhesive is applied in a liquid form and requires some time to cure and establish a strong bond. It can be applied using a hand dispenser or tape gun, and optimal adhesion often necessitates some pressure. Moreover, hot melt adhesive demonstrates excellent adhesion to a wide array of surfaces, including cardboard, plastics, and metals. Its versatility allows for usage with various packaging materials. While acrylic adhesive also adheres well to different surfaces, it may not exhibit the same level of compatibility with certain low-energy surfaces, such as polyethylene or polypropylene. Furthermore, temperature resistance is an essential factor to consider. Hot melt adhesive performs admirably in both high and low temperatures, maintaining its bonding strength. It can endure freezing temperatures and heat without compromising its adhesive properties. Acrylic adhesive, while generally offering good temperature resistance, may not be as effective in extreme conditions, particularly at very high or low temperatures. In conclusion, the primary disparities between acrylic and hot melt adhesives for packaging tape lie in bonding strength, the application process, surface compatibility, and temperature resistance. While hot melt adhesive provides superior bonding strength, rapid setting time, and excellent temperature resistance, acrylic adhesive offers versatility, ease of application, and good adhesion to most surfaces. The choice between the two depends on specific packaging needs, materials used, and environmental conditions.

- Q: Can packaging tape be used for sealing protective packaging materials like bubble wrap?

- Indeed, bubble wrap can be effectively sealed with packaging tape. The purpose of packaging tape is to establish a robust and secure seal on diverse materials, bubble wrap included. In the packaging and shipping sectors, it is widely employed to guarantee the safety and security of package contents throughout transportation. To ensure optimal protection and prevent any potential harm or exposure, it is essential to apply the tape along the edges of the bubble wrap, creating a snug seal.

- Q: Can packaging tape be used for mailing packages?

- Yes, packaging tape can definitely be used for mailing packages. It is specifically designed to securely seal packages and ensure they stay intact during transit. Packaging tape is strong and durable, making it ideal for securing boxes, envelopes, or other types of packaging materials. It is commonly used in shipping and mailing applications and is available in various sizes and strengths to accommodate different package sizes and weights. Whether you are sending a small envelope or a large box, packaging tape is an essential tool to ensure your package is properly sealed and protected during the mailing process.

- Q: How do I remove packaging tape without damaging the surface?

- To remove packaging tape without damaging the surface, you can try using a hairdryer to gently heat the tape, which will make it easier to peel off. Alternatively, you can use a small amount of rubbing alcohol or vinegar to dissolve the adhesive before carefully peeling it off. It's important to be patient and take your time to prevent any potential damage to the surface.

- Q: Is packaging tape resistant to mold or mildew?

- Yes, packaging tape is generally resistant to mold or mildew.

- Q: What's the problem of sealing the tape off?

- When the tape is pulled off, there are too many problems. I will answer the phone one day, and the tape will be broken. I said you will try another volume, or I will ask you to take a good look at the circumference of the tape

- Q: Can packaging tape be used for sealing pet supplies or accessories?

- Yes, packaging tape can be used for sealing pet supplies or accessories. It provides a strong and secure seal, ensuring that the items are protected and contained during transportation or storage.

- Q: Is packaging tape safe to use on plastic cutting boards?

- Packaging tape is indeed a safe option for plastic cutting boards. Its design enables it to stick to various surfaces, including plastic, without causing any harm or damage. It is commonly utilized for sealing packages and boxes, and does not contain any hazardous chemicals or substances that could jeopardize the plastic cutting board or the food being prepared on it. Nevertheless, it is crucial to acknowledge that utilizing packaging tape on a cutting board is not advised for reasons related to food safety. To avoid potential contamination, it is recommended to employ food-grade materials like food-safe adhesive tape or rubber bands to secure plastic cutting boards.

- Q: What is the cost of packaging tape?

- The cost of packaging tape can vary depending on factors such as brand, quantity, and quality. On average, a standard roll of packaging tape can range from $2 to $5. However, bulk packs or larger rolls may be available at a discounted price. Additionally, specialty or heavy-duty packaging tapes designed for specific purposes might be priced higher. It is recommended to compare prices from different suppliers or retailers to find the best deal that suits your packaging needs.

- Q: Is packaging tape safe to use on plastic shower curtains?

- Yes, packaging tape is safe to use on plastic shower curtains. It provides a secure and reliable way to attach or mend the curtains without causing any damage.

Send your message to us

Ace EZ Start Masking Tape of Low Tack in Various Colors

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords