Custom Water Activated Medium Tack Masking Tape in Various Colors and Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Medium Tack Masking Tape in Various Colors and Sizes

Interior paint masking, silk screening, Light duty packaging, bundling, holding, splicing &Tabbing, and other non-critical applications where a pressure-sensitive tape is needed.

Size of Medium Tack Masking Tape in Various Colors and Sizes

Paper Core ID: 76mm

Jumbo size: 0.99m x 1800m, 1.22m x 1800m, 1.51m x 1800m

Cut roll size: As per customer's requirement

Cut rolls: Shrink package, placed in cartons, with or without pallet

Packing of Medium Tack Masking Tape in Various Colors and Sizes

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

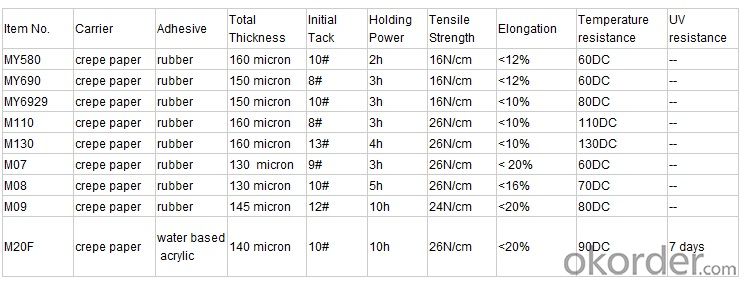

Technical Data of Medium Tack Masking Tape in Various Colors and Sizes

Picture Show of Medium Tack Masking Tape in Various Colors and Sizes

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s world wide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferencial shipping channels, with a separate team dealing with shipping.

- Q: Is packaging tape safe to use on plastic outdoor furniture?

- Packaging tape is generally considered safe for use on plastic outdoor furniture. It is designed to adhere to different surfaces, including plastic. However, before using packaging tape on your outdoor furniture, it is important to take several factors into account. First and foremost, ensure that the plastic surface is clean and free of dirt or debris. This will enhance the tape's adhesion and prevent any harm to the furniture. Additionally, apply the tape evenly and firmly to avoid any peeling or lifting issues. It is crucial to remember that packaging tape is not specifically created for long-term outdoor use. Although it can be effective in temporarily securing items or protecting surfaces, it may not endure prolonged exposure to severe weather conditions or UV rays. Over time, the tape may deteriorate or leave sticky residue on the plastic furniture. If you require a more durable and weather-resistant solution, it is advisable to utilize specific outdoor adhesives or tapes specifically designed for this purpose. These products are typically made with materials that can withstand outdoor elements and are better suited for long-term use on plastic outdoor furniture.

- Q: How do I remove packaging tape residue?

- To remove packaging tape residue, you can start by applying a small amount of oil or rubbing alcohol to a cloth or sponge and gently rubbing the affected area. This should help loosen the adhesive. Alternatively, you can also try using a mixture of warm water and dish soap, or a commercial adhesive remover. Make sure to test any method on a small, inconspicuous area first to ensure it doesn't damage the surface.

- Q: Can packaging tape be used for sealing office supplies or stationery?

- Certainly, office supplies or stationery can be sealed using packaging tape. This adhesive tape is highly versatile and frequently employed for sealing packages and boxes. Yet, it is crucial to take into account the size and weight of the item when using packaging tape for sealing smaller objects like office supplies or stationery. If the item is lightweight and the packaging tape is not excessively wide or bulky, it can serve as a convenient and effective option for sealing. Nevertheless, for smaller items, it might be more appropriate to utilize alternative types of tape, such as clear tape or double-sided tape, which are specifically designed for sealing stationery and office supplies.

- Q: Can packaging tape be used for sealing glass or delicate items?

- Yes, packaging tape can be used for sealing glass or delicate items. However, it is important to handle the items with care and apply the tape gently to avoid any damage. It is recommended to use a cushioning material like bubble wrap or foam to provide additional protection before sealing with packaging tape.

- Q: Can packaging tape be used for sealing foam or bubble wrap?

- Yes, packaging tape can be used for sealing foam or bubble wrap. It provides a secure and reliable seal, helping to protect the contents during transit or storage.

- Q: Can packaging tape be used for sealing cosmetic or beauty products?

- Sealing cosmetic or beauty products with packaging tape is indeed possible. However, it is crucial to consider the suitability of the chosen tape for the product's specific requirements. If the cosmetic or beauty item is sensitive to heat or moisture, it is advisable to opt for a specialized tape that offers enhanced protection against these elements. Moreover, ensuring that the selected packaging tape is safe for use on the skin or any part of the body is of utmost importance. Some tapes may contain adhesives or materials that could potentially cause irritation or allergic reactions. Therefore, it is recommended to carefully evaluate the specific needs of the cosmetic or beauty product and select a packaging tape that can effectively and safely meet those requirements.

- Q: How do I prevent packaging tape from losing its adhesive properties?

- To prevent packaging tape from losing its adhesive properties, it is important to store it in a cool, dry place away from direct sunlight and extreme temperatures. Additionally, ensure that the surface where the tape is applied is clean and free from any dust, oil, or moisture, as these can compromise the adhesive. Applying the tape firmly and evenly, avoiding excessive stretching, can also help maintain its adhesive strength.

- Q: What are the alternatives to packaging tape?

- There are numerous options available for securing packages or boxes instead of using packaging tape. Some of the popular choices are as follows: 1. Duct Tape: Known for its durability and ability to adhere to different surfaces, duct tape is a robust adhesive tape that serves as a viable alternative to packaging tape. 2. Masking Tape: Unlike packaging tape, masking tape possesses a lower level of stickiness. It is commonly utilized in painting or crafting projects, but can also be employed for securing packages. 3. String or Twine: A package can be secured by wrapping string or twine around the box and tying it tightly. This method is often used for packages that do not require a strong adhesive. 4. Packaging Straps: Made from plastic or polyester, packaging straps can be tightly fastened around the box to ensure secure packaging. They provide a reliable and sturdy alternative to packaging tape. 5. Adhesive Glue: For smaller packages or envelopes, adhesive glue can be used instead of packaging tape. It is crucial to select a strong glue that will securely seal the package. 6. Paper or Kraft Tape: Water-activated paper or kraft tape is commonly employed for sealing packages. The adhesive is activated by wetting the tape, resulting in a strong and secure seal. 7. Zip Ties: Zip ties, which are plastic ties, are often used for securely fastening large or heavy packages by tightly encircling the box. To determine the most suitable alternative to packaging tape, it is vital to assess the specific requirements of the package, including its size, weight, and handling needs.

- Q: How does packaging tape perform on metal surfaces?

- Packaging tape generally performs well on metal surfaces. Its adhesive properties allow it to adhere securely to metal, providing a strong bond. The tape is designed to withstand various environmental conditions, including temperature fluctuations and moisture, ensuring that it remains intact on metal surfaces. Additionally, packaging tape is typically durable and tear-resistant, making it suitable for long-term use on metals. However, it is essential to ensure that the metal surface is clean and free from any oils or debris before applying the tape, as this can affect its adhesion. Overall, packaging tape is an effective and reliable option for securing items to metal surfaces during packaging and shipping processes.

- Q: Is packaging tape easy to remove without damaging surfaces?

- Packaging tape is generally designed to be easily removable without causing damage to surfaces. However, the ease of removal can vary depending on several factors such as the type and quality of the tape, the surface it is applied to, and the length of time it has been in place. Most packaging tapes are designed to adhere firmly to surfaces during transit or storage, ensuring that the package remains sealed and secure. However, they are also designed to be peeled off easily when needed, without leaving behind residue or causing damage. In most cases, packaging tape can be removed by simply peeling it off slowly and evenly. The adhesive used in packaging tapes is typically formulated to have a good balance between adhesion and removability. This allows for easy removal without requiring excessive force or leaving behind sticky residue. However, there can be instances where the tape may be more difficult to remove, especially if it has been in place for an extended period or exposed to extreme temperature conditions. In such cases, it may be helpful to use heat (such as a hairdryer) to soften the adhesive, making it easier to peel off. It is worth noting that the ease of tape removal can also depend on the surface it is applied to. Smooth, non-porous surfaces like glass or metal are generally easier to clean without any damage. On the other hand, porous or delicate surfaces like wood or painted walls may require more caution and care during removal to avoid any potential damage. In conclusion, while packaging tape is generally easy to remove without damaging surfaces, it is important to consider factors such as tape quality, surface type, and removal technique to ensure a smooth and damage-free removal process.

Send your message to us

Custom Water Activated Medium Tack Masking Tape in Various Colors and Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches