High Tack Masking Tape with No Residue - Packaging Tape Specification

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of Masking Tape of High Tack with No Residue

Interior paint masking, silk screening, Light duty packaging, bundling, holding, splicing &Tabbing, and other non-critical applications where a pressure-sensitive tape is needed.

Size of Masking Tape of High Tack with No Residue

Paper Core ID: 76mm

Jumbo size: 0.99m x 1800m, 1.22m x 1800m, 1.51m x 1800m

Cut roll size: As per customer's requirement

Cut rolls: Shrink package, placed in cartons, with or without pallet

Packing of Masking Tape of High Tack with No Residue

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

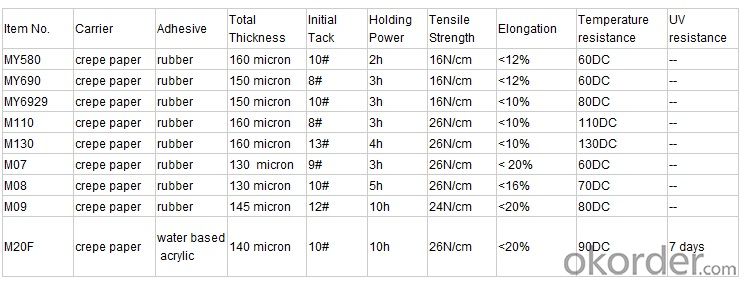

Technical Data of Masking Tape of High Tack with No Residue

Picture Show of Masking Tape of High Tack with No Residue

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s world wide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferencial shipping channels, with a separate team dealing with shipping.

- Q: Is packaging tape resistant to chemicals?

- Packaging tape is typically resistant to a wide range of chemicals. Most packaging tapes are made from materials such as polypropylene or polyvinyl chloride (PVC), which are known for their chemical resistance properties. These materials have the ability to withstand exposure to various chemicals, including solvents, acids, and bases. However, it is important to note that the level of chemical resistance can vary depending on the specific type and quality of packaging tape being used. Some tapes may have a higher resistance to chemicals than others. Additionally, the duration and intensity of chemical exposure can also affect the tape's resistance. To ensure the tape's chemical resistance, it is recommended to check the manufacturer's specifications and guidelines regarding chemical compatibility. If you are dealing with particularly harsh chemicals or specialized applications, it may be necessary to seek out specific types of packaging tapes that are specifically designed for those conditions.

- Q: How do I prevent packaging tape from losing its color over time?

- To prevent packaging tape from losing its color over time, it is essential to store it properly. Keep the tape in a cool and dry place, away from direct sunlight or excessive heat. Exposure to these elements can cause the color to fade. Additionally, make sure the tape is tightly sealed after each use to prevent any air or moisture from affecting its color.

- Q: Can packaging tape be used for sealing paper bags?

- Indeed, paper bags can be securely sealed with packaging tape. Possessing robust adhesive properties, packaging tape effectively adheres to diverse surfaces, including paper. When appropriately applied, it furnishes a dependable and safeguarding seal for paper bags, effectively shielding their contents from spillage or external influences. To optimize adhesion, it is crucial to ascertain that the surface of the paper bag is both clean and dry prior to tape application.

- Q: What are the benefits of using double-sided packaging tape?

- The benefits of using double-sided packaging tape include increased strength and stability of packages, improved adhesion to various surfaces, ease of use, and the ability to securely seal items without the need for additional materials such as glue or staples.

- Q: Is packaging tape safe for use on painted surfaces or walls?

- Packaging tape is generally considered safe when used on painted surfaces or walls. However, it is crucial to exercise caution and employ proper techniques to minimize the risk of potential damage. To ensure that the tape does not peel off or harm the paint, it is advisable to first test a small, inconspicuous area before applying it. Moreover, it is recommended to remove the tape gently and slowly to avoid any paint peeling or residue. In cases where the paint is delicate or the tape has been left on for a prolonged period, there is a slight possibility of minor damage such as slight paint discoloration or removal. Therefore, it is always wise to handle packaging tape with care and take necessary precautions to safeguard the painted surfaces or walls.

- Q: What is the profit margin of the transparent tape for packaging?

- Now, many of the tapes are closed and the profits are too transparent

- Q: What's the tape for sealing tape?

- The base material of the sealing adhesive tape is BOPP film.BOPP is a very important flexible packaging material, and has been widely used. BOPP film is colorless, odorless, tasteless, non-toxic, and has high tensile strength, impact strength, rigidity, toughness and good transparency. It is a high quality substrate for making transparent sealing tape. BOPP film has low surface energy, and it needs corona treatment before gluing or printing. However, the BOPP film has good printing adaptability after corona treatment. It can be printed by printing and has a beautiful appearance, so it is often used as the surface material of composite films. BOPP film is also inadequate, such as easy accumulation of static electricity, no heat sealing and so on. In the high-speed production line, BOPP film is easy to generate static electricity. Electrostatic eliminator is necessary. In order to obtain the BOPP heat seal film, can be on the surface of BOPP film after corona treatment coating heat sealing resin glue, such as PVDC, EVA latex latex, can also be coated with solvent glue, coating or extrusion method can be applied to the production of extruded composite heat sealing film BOPP. The film is widely used in bread, clothing, footwear and other packaging, and cigarettes, books cover packaging. The tear strength of BOPP film increases after stretching, but the secondary tearing strength is very low. Therefore, no cut can be left at the ends of the BOPP film, otherwise the BOPP film is easy to tear when printed and compounded. BOPP coated self-adhesive, we can produce our commonly used sealing tape, tape sealing tape, is a larger amount of BOPP market.

- Q: What are the benefits of using transparent packaging tape?

- The benefits of using transparent packaging tape include clear visibility of the contents of the package, easy identification of any tampering or damage, professional appearance, and the tape's durability and strength for securing packages effectively.

- Q: General adhesive tape is a taste, the size of the taste depends on the formula of glue, low molecular weight content, taste will be larger, once adhesive tape, it has a very small taste tape, we have been using.

- Slitting machine pressing wheel with a belt, in cutting the air away, if you want to good effect, the sub machine pressing wheel to large and soft (preferably with 20CM diameter), so the effect will be much better than disadvantage is cut cut the tape surface appearance;

- Q: Can packaging tape be used on different surfaces, such as cardboard, plastic, or metal?

- Yes, packaging tape can be used on different surfaces such as cardboard, plastic, or metal. Packaging tape is designed to provide a strong and secure seal, making it suitable for various materials. It adheres well to the rough surface of cardboard, ensuring that boxes and packages remain securely sealed during transit. Additionally, packaging tape can adhere to smooth surfaces like plastic, ensuring that items are securely packaged and protected. It can also be used on metal surfaces, providing a reliable seal for packages and boxes made of metal. Overall, packaging tape is versatile and can be used on different surfaces, making it an essential tool for packaging and shipping needs.

Send your message to us

High Tack Masking Tape with No Residue - Packaging Tape Specification

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 200000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches