Packaging Tape for Shipping - Masking Single Side Rubber Adhesive Auto Painting Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8500 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Product details

Item | NKS-3565SIG | NKS-5080SIG |

Color | Clear/Green/Blue | Clear/Green/Blue |

Carrier | Polyester | Polyester |

Adhesive | Silicone | Silicone |

Carrier Thickness (mm) |

0.035 |

0.05 |

Adhesive Thickness (mm) |

0.025 |

0.03 |

Total Thickness (mm) |

0.06 |

0.08 |

Adhesion (N/25mm) | 6 | 6 |

Tensile Strength (N/25mm) |

135 |

220 |

Elongation at Break (%) | 40 | 50 |

Corrosion Resistance | 1 | 1 |

Storage Condition | 20°C,65RH | 20°C,65RH |

Long Term Heat Resistance (°C) |

180 |

180 |

Short Term Heat Resistance (°C) |

220 |

220 |

2.FEATURES

(1)High temperature masking

(2)Powder coating masking

(3)High temperature resistance without adhesive residue

(4)Plasma spraying

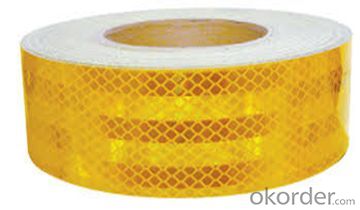

3. product show

4.Product Description

(1) High quality cured rubber-adhesive which is designed for good adhesion and no-residue removal, with the temperature resistance to 70℃-150℃.

(2)Cut and packed by Italy automotive cutting and packing machine, with the perfect trim margin of the tape, easy to peel and no break.

(3) Good to write on the tape surface, easily use for marking.

5.About us

China National Building Material Group Corporation(CNBM), estiblished in 1984, as the largest group corporation of building materials in China. It ranked the 267th among the global FORTUNE 500 CORPORATIONS. And it's a China state-owned enterprise, ranked the 143 large-scale groups under the administration of the state-owned Assets supervision and administration commission of the state council.

With thelargest geosynthetics base about 667000m2 in China and have about 120production lines for all geo materials. For geotextile, our production capacity each day can be 300,000m2. We warmly welcome your order and visit. CNBM guarantee good quality and serivce with comptetitive prices.

- Q: 2014, how can I sell the tape better?

- Fourth, the background of your company must say company influence and company history,Fifth, the market prospects and profit margins, regardless of the price of your products is how much of that is not a problem, and if you have a small list of hands, you can put the list to be introduced to customers, these are my experience to sell, can only give you a reference, are different for each personal selling, to try to know,

- Q: How does packaging tape perform on oily or greasy surfaces?

- Packaging tape generally does not perform well on oily or greasy surfaces. The adhesive on packaging tape is designed to bond to clean and dry surfaces, so when applied to oily or greasy surfaces, the tape may struggle to stick securely. The oil or grease can act as a barrier, preventing the adhesive from effectively bonding to the surface. As a result, there is a higher probability of the tape peeling or coming loose. To ensure proper adhesion on oily or greasy surfaces, it is recommended to thoroughly clean and degrease the surface before applying packaging tape. Using a degreasing agent or detergent can help remove the oil or grease, allowing the tape to adhere more effectively. Additionally, selecting a high-quality packaging tape with a strong adhesive can also help overcome the challenges posed by oily or greasy surfaces.

- Q: Is packaging tape safe for use on delicate surfaces or materials?

- Packaging tape is generally not recommended for use on delicate surfaces or materials. It is designed to provide a strong and secure bond on sturdy surfaces such as cardboard boxes. Using packaging tape on delicate materials may cause damage, leave residue, or negatively affect the appearance of the surface. It is advisable to use specialized tapes or alternative methods to protect delicate surfaces during packaging.

- Q: Can packaging tape be used for sealing metal containers or boxes?

- Yes, packaging tape can be used for sealing metal containers or boxes as it provides a strong adhesive bond and can effectively secure the contents inside. However, for heavy-duty or industrial applications, it is recommended to use specialized tapes designed specifically for sealing metal surfaces.

- Q: How do you choose the right packaging tape for your needs?

- When it comes to selecting the appropriate packaging tape for your requirements, there are various factors to take into consideration. To begin with, ponder over the nature of the items you will be packaging. If you are dispatching weighty or bulky items, you will need a tape that is sturdy and long-lasting, such as a heavy-duty or reinforced tape. Conversely, if you are packaging lightweight items, a standard packaging tape may suffice. Moving forward, contemplate the surroundings in which the package will be stored or transported. If the package will be exposed to extreme temperatures or moisture, it is advisable to opt for a tape that is resistant to these conditions, such as a weather-resistant or waterproof tape. This will ensure that your package remains intact and safeguarded throughout its journey. Furthermore, take into account the surface onto which the tape will be affixed. If you are packaging boxes with smooth surfaces, a standard adhesive tape will suffice. However, if you are packaging boxes with rough or textured surfaces, you may require a tape with a stronger adhesive, such as an acrylic or hot melt tape, to ensure proper adhesion. Additionally, consider the length and width of the tape roll. If you will be packaging a large number of items, it may be preferable to select a tape roll with a longer length to minimize the need for frequent replacements. Similarly, if you are packaging larger boxes, a wider tape roll may provide better coverage and security. Lastly, take your budget into account. Packaging tapes are available in a range of prices, so it is crucial to strike a balance between your needs and your budget. While it may be tempting to opt for cheaper options, bear in mind that investing in a higher-quality tape can save you time, effort, and potential damages in the long run. By considering the type of items, environmental conditions, surface texture, roll length and width, and your budget, you can choose the appropriate packaging tape that caters to your specific needs and offers the necessary strength, durability, and security for your packages.

- Q: Can packaging tape be used for sealing camping or outdoor gear?

- Certainly! Packaging tape is suitable for sealing camping or outdoor equipment. Its primary purpose is to securely seal boxes and packages, offering a sturdy and long-lasting seal. It can also be utilized to seal openings or tears in fabric-based camping gear like tents, sleeping bags, backpacks, and other items. However, it is crucial to acknowledge that packaging tape might not be as effective as specialized outdoor gear repair tape, which is explicitly crafted to endure harsh outdoor conditions and provide a more resilient and enduring seal. Moreover, when using packaging tape to seal camping gear, it is advisable to clean and dry the area before applying the tape to ensure an appropriate bond.

- Q: What are the considerations for using packaging tape on textured surfaces?

- When using packaging tape on textured surfaces, it is important to consider the adhesion and durability of the tape. The texture of the surface can affect how well the tape sticks and stays in place. It is advisable to choose a tape with strong adhesive properties that can effectively bond with the texture of the surface. Additionally, the tape should be able to withstand any movement or stress that may occur due to the textured surface. It is also crucial to ensure that the tape does not damage or leave residue on the textured surface when it is removed.

- Q: Is packaging tape resistant to moisture or humidity?

- Indeed, packaging tape typically exhibits resistance to moisture and humidity. The majority of packaging tapes incorporate materials like polypropylene or acrylic, renowned for their capacity to endure moisture and humidity. These tapes are purposefully crafted to establish a robust seal on boxes and packages, effectively thwarting the infiltration of water or moisture. Furthermore, packaging tapes frequently boast an adhesive that is meticulously formulated to retain its stickiness, even amidst humid conditions. Nevertheless, it is crucial to acknowledge that the extent of resistance may fluctuate depending on the precise type and caliber of packaging tape employed.

- Q: Does packaging tape have an expiration date?

- Packaging tape typically does not have an expiration date. This is because packaging tape is usually made from durable materials such as polypropylene or PVC, which have a long shelf life and do not degrade easily over time. As long as the tape is stored in a cool, dry place, away from direct sunlight and extreme temperatures, it should remain effective for a long period. However, it is important to note that the adhesive on packaging tape may lose its stickiness over time, especially if it is exposed to heat or moisture. So, while packaging tape may not have an official expiration date, it is advisable to use it within a reasonable timeframe to ensure its adhesive properties are still intact.

- Q: How does packaging tape perform in dusty environments?

- Packaging tape generally performs well in dusty environments, but its effectiveness may vary depending on the specific conditions and the quality of the tape. Dust particles can potentially interfere with the adhesion of the tape, making it less sticky and less reliable in securing packages. However, most packaging tapes are designed to be resistant to dust and other contaminants, and they have a strong adhesive backing that can withstand moderate levels of dust. In dusty environments, it is recommended to choose packaging tapes that have a higher tack or adhesive strength. These tapes are specifically engineered to provide better adhesion and stickiness, even in dusty conditions. Additionally, selecting tapes with a thicker backing material can also help to prevent dust particles from penetrating through the tape and compromising its adhesive properties. It is important to note that excessive dust accumulation may still impact the performance of packaging tape, especially if the dust is fine and abundant. In such cases, it is advisable to regularly clean the package surfaces before applying the tape to ensure optimal adhesion. Adequate surface preparation, such as wiping down the area with a clean cloth or using compressed air to remove the dust, can help improve the tape's performance in dusty environments. Overall, while packaging tape can generally perform well in dusty environments, it is essential to consider the quality of the tape, the level of dust exposure, and the proper surface preparation to ensure optimal adhesion and package security.

Send your message to us

Packaging Tape for Shipping - Masking Single Side Rubber Adhesive Auto Painting Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8500 m

- Supply Capability:

- 500000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords