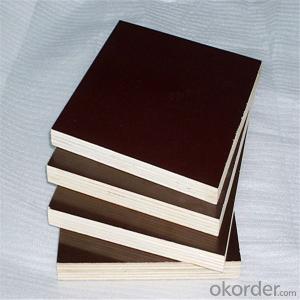

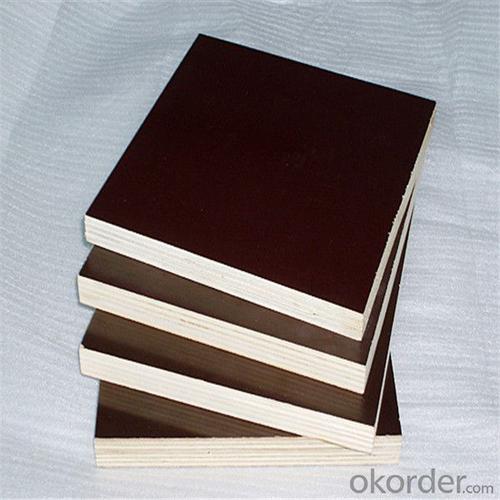

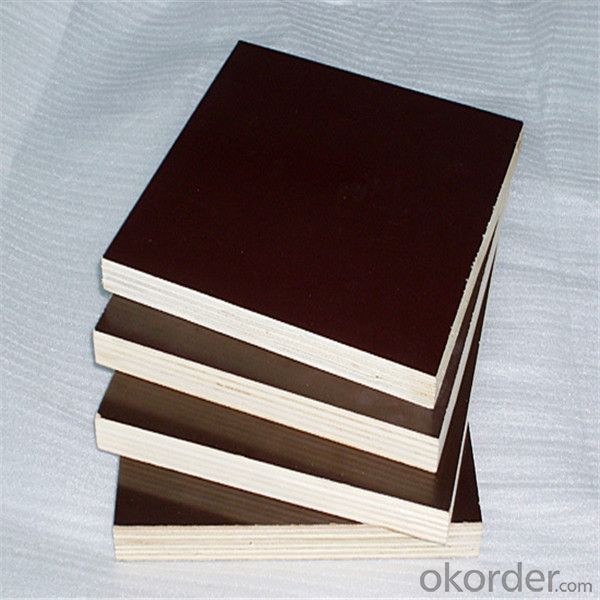

4x8x3/4 Marine Waterproof Film Faced Plywood Made in China

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION

size | 1220*2440mm,1250*2500mm,915*1830mm,1500*3000mm |

Core: | Poplar,hardwood,birch,combine |

thickness | 9mm,12mm,15mm,18mm,20mm,21mm |

film | Black film, domestic brown film, imported dynea brown film |

Length(width) tolerance | +/-0.2mm |

Thickness tolerance | +/-0.5mm |

edge | Sealed with waterproof paint |

glue | MR, WBP |

moisture | 6-14% |

packing | Standard exporting package( bottom is pallet, covered with plastic film, around is carton, strengthen by steel tape with 3*6 |

usage | Usded for construction, building house, flooring,shopping mall… |

Payment term | TT or L/C at sight |

Delivery time | Within 35 days after get prepayment |

FEATURE

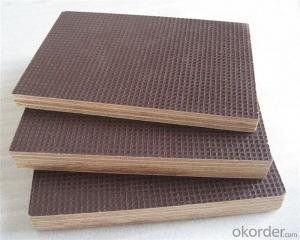

1, Transference to concrete is set up very easily, so good for construction work |

| 2, Waterproof, Wear-resistant, anti-cracking. |

| 3, After installation of concrete, the surface looks like a mirror. (The cement does not stick.) |

| 4, It can be used to make camber and it also can be cut into small pieces according the special requirements. |

| 5. Environmentally friendly |

| 6 It can be used for a long time, and for the initial price paid for the material, you will feel its worth over time |

SPECIFICATION

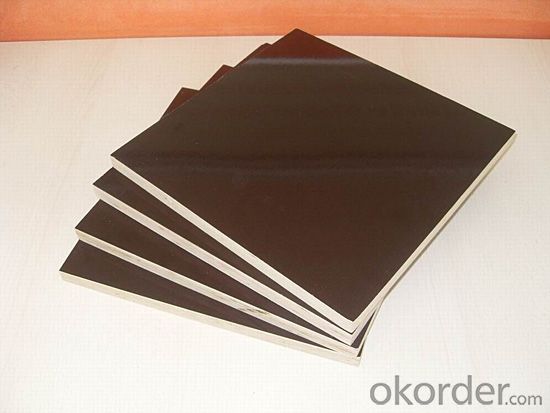

Film: Black, Brown

Size: 1220x2440mm(4'x8'), 1250x2500(4.1'x8.2'),610mmx2440mm(2'x8')

Thickness: 9-21mm

Thickness: Within +-0.3mm-+-0.5mm, can as client's request

Number of Plies: From 9 to 13 depending on thickness and client's request.

Core: Poplar, Hardwood, Birch, Combined

Glue: WBP, Melamine, MR

Surface: smooth and Anti-slip

- Q: What is the general use of plywood in decoration works?

- usually with odd-level veneer, and the adjacent layer of veneer Of the fibers are perpendicular to each other.

- Q: Commonly used plywood, pallets and so on

- Is the destruction of the physical properties of the wood itself, which played a leading role in the composition of the plastic

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- on the requirements of the multi-layer solid wood flooring as strict, which is our daily common plywood or plywood bending reasons.

- Q: Contemporary plywood market development

- but also China's development of plywood industry cost accounting and other plywood production countries compared to the advantages of an important factor. China plywood product quality itself

- Q: What are the processing defects of plywood?

- Warping warPing is generally a regular deformation, part or all of the surface of the plywood is curved.

- Q: What are the key points for plywood selection?

- panel decoration need to use transparent varnish (also known as oil), to retain the natural color of wood surface and texture, should focus on the panel material, pattern and color selection

- Q: Multilayer board, also known as three plywood and plywood

- usually with odd-level veneer, and the adjacent layer The fiber orientation of the veneer is perpendicular to each other

- Q: Distinguish between multilayer boards and plywood

- With the veneer after the wood by the direction of the criss-cross the composition of the slab, heated or not heated under the conditions of suppression.

- Q: The basic principle of plywood

- The principle of symmetry is to require plywood symmetry on both sides of the plate, regardless of the nature of the wood, the thickness of the plywood, the layer, the fiber direction, the water content, etc

- Q: Does plywood contain formaldehyde?

- If there is formaldehyde or cyanide and other toxic substances in the glue used in the system board, then the plate is toxic, and you can use these plates to make furniture. These furniture are poisonous.

Send your message to us

4x8x3/4 Marine Waterproof Film Faced Plywood Made in China

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords