18mm Melamine Faced MDF Board - Both Sides or One Side - All Colors - E2 Grade - CMAX - China and Dubai

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 37 m³

- Supply Capability:

- 3700 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

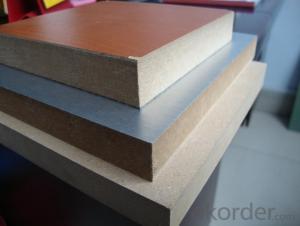

Melamine MDF is a MDF board with melamine faced in varieties of colors. This kind of MDF board is widely used for decoration and furniture. Besides the face, it has a same specification as MDF stands for Medium Density Fiber Board. These types of boards are denser and stronger than particle boards. MDF boards are available in interior as well as exterior grade. MDF is made from very fine particles or wood called wood fibers. Glue is mixed with these particles and mixture is compressed under high pressure and temperature to make boards. Urea formaldehyde based resin is mixed with the wood fibers to make the boards.

Packaging & Delivery

(1).Packaging Detail: pallets package as standard shipment request.

(2).Delivery Detail: There are two options for customer.

(A).Stock from Jebel Ali Free Zone warehouse in Dubai, delivery available in one day after payment received.

(B).Booking from factories, delivery in 40 days after PI confirmed.

Specifications of Melamine MDF Board (Brand name: CMAX)

(1)Size: 1220 mm×2440 mm, other special sizes.

(2)Thickness: 18mm

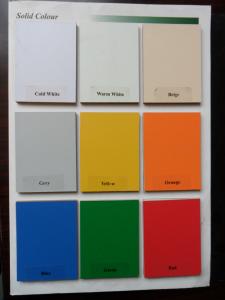

(3)Color: White, Black, Mahogany, Golden Beech, all colors available for booking.

(4)Glue: E2 or E1, E0

(5)Film: Melamine, Both sides or One side

(6)Origin: China

(7)Moisture: 9%-15%.

(8)Thickness tolerance: +/-0.05mm

(9)Density: 700-760kg/m³

(10)Payment: T/T or L/C at sight

(11)Manufacture in China or Stock in Dubai-UAE

Advantage of Melamine MDF Board:

(1).Perfect material for furniture design has a smooth face like mirror.

(2).High strength for furniture and decoration.

(3).Stability.

(4).Resilience.

(5).Permanent melamine faced with varieties of colors for furniture and decoration.

(6).Excellent screwing holding power.

(7).Easy to clean.

(8).Wear resistance.

(9).High temperature resistance.

Uses:

(1). Commercial building.

(2). Residential condominiums.

(3). Boutique & store fixtures.

(4). Kitchen & bath application.

(5). Government & bank buildings.

(6). Home organization & storage.

(7). Furniture & shelving application.

(8). Hospital & clinics.

(9). Schools & Libraries.

- Q: What is called a panel?

- Plywood, is used in the decorative trim plywood, and some plywood to paint finishing, and some are paint-free, the specifications are long 2440MM wide 1220MM.

- Q: What is the price of decorative veneer?

- To the splint as the substrate, made by the adhesive process made with a single decorative effect of the decorative plate.

- Q: Plywood hot press and plywood hot press is different

- Uses: veneer press models for neutral furniture factory or small man-made board secondary processing (professional veneer) factory, used for hot pressing adhesive furniture panels, building partitions, wooden doors and in a variety of wood-based panels

- Q: What is the plate? Is it really environmentally friendly?

- Ordinary melamine plywood has long been in the domestic production, was originally used to do computer desk and other office furniture, mostly monochrome board, including everyone familiar with the "double white" "double gray." With the popularity of furniture in the family, melamine plywood gradually become the first choice for the furniture factory manufacturing materials,

- Q: The good and the bad of wood is not determined by the severity

- 4, smell: with the nostril paste into the material smell, if the blockboard fragrance smell, indicating formaldehyde content is low, if the smell of pungent is a higher formaldehyde content.

- Q: What is the difference between a melamine plywood and a flat sheet?

- Coated flat paste board refers to the quality of man-made board covered with a layer of coated paper, coated paper and wood-based panels by thermal pressure and the formation of building cover plate;

- Q: Melamine plywood (do board with the board) dirty how to clean

- Use gasoline (wash clean) and other detergent such as, do not use thinner and banana water and the like

- Q: What are the advantages and disadvantages of decorative panels?

- Melamine veneer makes the appearance of furniture strong, printed with color or imitation wood grain of paper itself is fragile, melamine plate in the transparent resin soaked in the formation of the film after the film to be hard, this film and the substrate hot pressing Into a body has a very good performance, with it to fight the furniture do not have to paint, the surface of the natural formation of protective film, wear, scratch resistance, Naisuan Jian, resistant to heat, pollution.

- Q: What is the thickness of the trim panel?

- The thickness of the panel is usually 3mm, but there are some other thickness of 0.9mm, 1.2mm, 1.5mm, 1.8mm, 2.0mm, 2.7mm / 3.0mm, 3.6mm, etc., the thicker the better the performance, The more true, the more clear texture, bright color saturation is good.

- Q: Home improvement commonly used plate which?

- Particleboard technology: wood chips and wood scrap, plus adhesive after pressing.

Send your message to us

18mm Melamine Faced MDF Board - Both Sides or One Side - All Colors - E2 Grade - CMAX - China and Dubai

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 37 m³

- Supply Capability:

- 3700 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords