36 Fiberglass Mesh Marble Mesh, 65g/m2, 20*10/inch, Plain Weaving

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

FOB Price of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving US $0.22/ Square Meter

MOQ of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving: 10000 Square Meters

Supply Ability of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving: 6000000 Square Meters per Month

Payment Terms of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving: L/C,T/T

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

Specifications of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Place of Origin: China (Mainland)

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Brand Name: CMAX

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Application: Wall Materials

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Width: 1M-2M

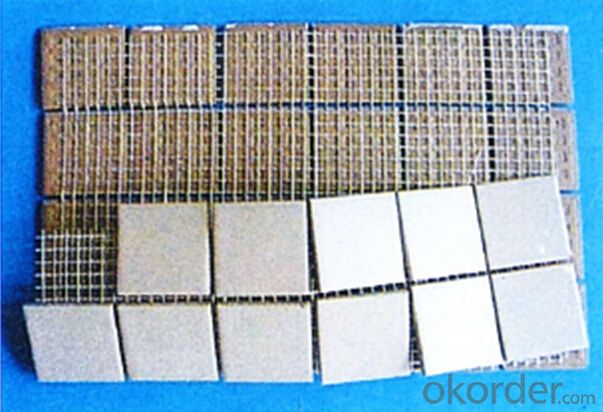

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Size: 5*5/ INCH

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Weight: 40gsm to 200gsm

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Weave Type: Plain Woven

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Yarn Type: C-Glass

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Alkali Content: Medium

Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving Standing Temperature: 500℃

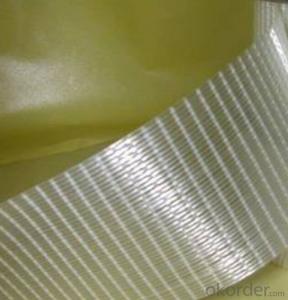

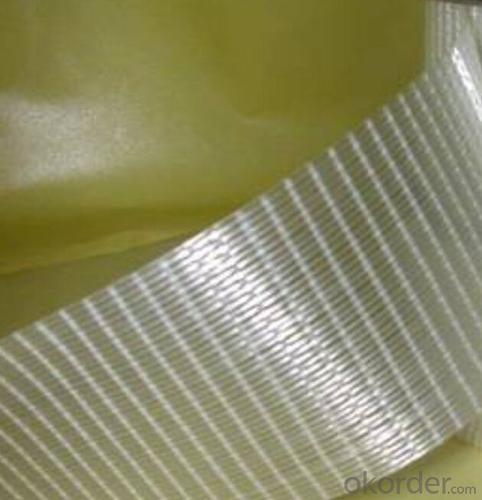

Product information of BASF Glue Coated Marble Backing Mesh

Name: Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

Use best fiberglass yarn and best glue

Clear and beautiful Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

High strength Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

30 years experience of manufacturing Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

Excellent Priced Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

FAQ of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

Q: What is Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving?

Coated Alkali-resistant Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving

Weight: 65g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving?

Marble slab reinforcement / Mosaic carrier

Q: What is the storage of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving?

Four years under normal weather conditions and use .

Q: What is the package of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of Marble Mesh, 65g/m2, 20*10/Inch, Plain Weaving?

Production periods: 30days for 1X40HQ.

- Q: Mesh cloth tape, that is, fiberglass self-adhesive tape, how to use?

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion. Therefore, the utility model has the advantages of good alkali resistance, flexibility, and high tensile resistance at warp and weft direction. The utility model can be widely used for heat preservation, water resistance and crack resistance of walls inside and outside buildings.

- Q: The difference between glass fiber and carbon fiber

- The chemical composition is completely different. The glass fiber is characterized by its low price, high physical performance, high carbon fiber price, but very good physical properties such as tensile strength, and the most important one is the light quality

- Q: With regard to the wall cracking treatment, decration team recommends to fully paste mesh.

- It is a bit of right, buy dacron cloth will be better.

- Q: Is glass fiber harmful to human body?

- Pulmonary function measured by FVC (forced expiratory volume) was lower than normal, but much less severe than asbestos workers. Pathological examination of lung biopsy of exposed glass fiber workers showed that there were glass fiber dust cell foci in lung tissue, slight hyperplasia of gum elements, lung cancer and lung abscess. When exposed to lower concentrations (2.5 ml / ml), the lung function of the workers was not changed even for up to 20 years.

- Q: For puttying in decoration, anti-cracking fiberglass mesh or dacron cloth is widely used on walls. What are the correct constrcution order and method?

- If it is not sticked firmly, use white latex strip to attach bar-type anti-cracking cloth at the seams. Brush some white latex on anti-cracking cloth again.

- Q: Exterior wall insulation, alkali resistant mesh cloth in the door window flip bag approach?

- The doors and windows should be done to strengthen bladder surrounding layer, strengthening layer grid cloth on the inside of the door window frame. If the skin and the base wall surface is larger than the 50mm mesh and the base wall paste. If less than 50mm, you need to do the package disposal. Great wall laying mesh should block entry window outside of cement.

- Q: When mineral varnish finishing is used for external wall thermal insulation, can fiberglass mesh be used?

- It is no problem.

- Q: What is fiberglass strainer?

- Glass fiber screen is mainly used in industrial clean room, chip workshop, operation room, high-end purifier and high-end fresh air system.

- Q: What is the function of epoxy resin mesh

- it is mainly used for the casting transformer and electric reactor, soaking in the epoxy resin, and the mesh of H level epoxy glass is using the alkali-free glass fiber with high insulation grade, no partly emission and no bubble in the interior. The product is impregnated throughly in the epoxy resin, solidified and sizinged by drying, and the terylene interweaving to the square opening gridding and the gray cloth is dehydrated by high temperature.

- Q: what kind of glue does the mesh used on the rubber?

- Relatively easy to be broken, and the hand feeling of softness is good and the positioning time is kept in a long time and the function of alkali resistant, the glass fiber mesh coated with emulsion is not alkali resistant, and positioning is easy to return to the glass fiber mesh coated with glue. If it is an emulsion with glue and then you can add a small amount of plastic glue.

Send your message to us

36 Fiberglass Mesh Marble Mesh, 65g/m2, 20*10/inch, Plain Weaving

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords