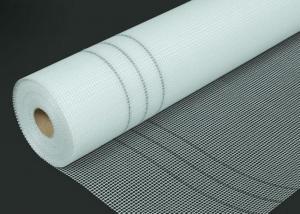

Fiberglass Mesh 160g

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000m2 m²

- Supply Capability:

- 1x40HQ Per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Fiberglass Mesh

Fiberglass mesh is mainly alkali-resistant fiberglass fabric, it use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. It's an ideal engineering material in construction and decoration industry.

Mesh size: 5mm x 5mm, 4mm x 4mm, or 4mm x 5mm

Weight/m2: 160g

Length/roll: 50m-100m

Width: 1m

Color: white, blue, orange or other colors

Special spec can be ordered and produced by the requirements of customers

Usage/Applications of Fiberglass Mesh

160g / m2 mesh fabric used in insulator layer of reinforcement in the mortar, through shrinkage and temperature changes by providing a space to maintain movement between the layers, prevent crack and rupture due to shrinkage or temperature change.

Packaging & Delivery of Fiberglass Mesh

Packaging: Each roll is shrink-wrapped, or to be packed in plastic bag. Then rolls are put into pallets and cartons.

Delivery: About 10 days after confirming the order.

Characteristics of Fiberglass Mesh

1. Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

2. Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

3. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

4. Strength retention rate> 90%, elongation <1%, the durability of more than 50 years.

5. Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property.

6. Good impact resistance and not easy to be teared.

- Q: What is the strengthening measure of plastering engineering with the thickness greater than or equal to 35mm?

- Plastering thicknessDifferent parts of plastering base require different plastering thickness.The ordinary plaster - 18mm; the surface is smooth, clean, smooth jiecha.Intermediate plastering 20mm; the surface is smooth, clean, all smooth, straight clear line angle.Advanced plastering - 25mm. Smooth surface, clean, uniform color, no wiping lines, line angle and gray line upright, clear and beautiful.

- Q: When doing exterior wall insulation, should you first put mesh cloth, and then play the anchor bolt, or first play the anchor bolt, then mesh cloth, why?

- Rock wool board insulation wall dry hanging stone, rock wool board construction directly hit the anchor nails do not wipe mortar does not hang mesh you first look at the rock wool board of Engineering with tensile strength specifications and Xishuishuai size, if the tensile strength is greater than

- Q: What are the main applications of fiberglass mesh?

- Special net for granite, mosaic, marble back net

- Q: What is a barbed wire glass fiber gridding cloth?

- Barbed wire is a kind of protective products and mainly used for orchard, fish, protection. Glass fiber gridding cloth is different from it and generally used for thermal insulation wall.

- Q: How to choose glass fiber filter cartridge

- The first is the filter, dust filter filter is the most critical, 240 grams of domestic polyester long fiber filter material is one of the most widely used industry dust filter, filter must be used with caution, and certainly not with 220 grams or 200 grams of alternative, it will shorten the service life of the filter cylinder. For fixed paper folded paper and bandage it is best to choose cotton material thicker material, adhesive bandage can not be fixed with ordinary hot melt adhesive, otherwise the cartridge will you like a balloon blown explosion.

- Q: What is the function of plaster and steel wire netting in Chinese and foreign wall plastering?

- Two kinds of hanging wire, a wall insulation, a construction process, because the majority of the high-rise hollow block, concrete hollow block and the expansion coefficients are not the same, easy to crack, resulting in external wall seepage and influence appearance, generally does not require full hanging, hanging parts: requirements the horizontal hanging wire mesh - the need to consider the block wall and concrete beams intersect, masonry walls and concrete columns (wall) intersection, block and beam gable intersect.

- Q: When the outer insulation lacquer decorative glass fiber cloth can do it

- But at present the market of Internet cloth quality differences. The poor mesh cloth basically can not reach the effect of anti cracking. Please add me.

- Q: What's the gridding cloth? What's the application of them?

- With glass fiber woven fabric as base material, gridding cloth is processed with high alkali emulsion. GRC products are featured by high strength, lasting alkali resistance. Cement and concrete products, GRC wallboard and GRC components.

- Q: What are the types of glass fiber gridding cloth?

- Specifications for gridding cloth for external walls: 70-160/g. Gridding cloth for external walls is featured by low cost, messy layout, high resistance to alkali, corrosion and cracking, easy construction. It is used for strengthening cement plaster wall.

- Q: Is it first posted mesh or putty?

- In fact, concrete walls can directly whitewashing, it is not easy to crack because of the integrity of the wall, it can do not stick mesh. This shinkage is only occured in the filling wall through plastering, and now there flexible putty to do whitewash, and then stick mesh (mesh can fitst also be sticked), thus the crack will be reduced.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Fiberglass Mesh 160g

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000m2 m²

- Supply Capability:

- 1x40HQ Per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords