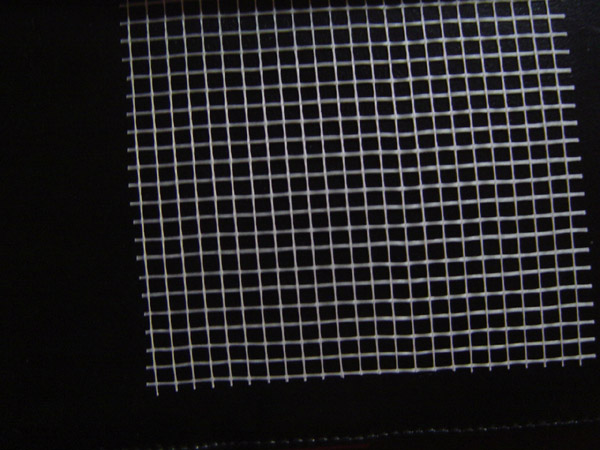

Laticrete Fiberglass Mesh Tape - 60g Fiber Glass Mesh Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Product Introduction

Fiberglass mesh, alkali resistant fiberglass mesh is on the basis of alkali-resistant or C-glass or E-glass woven fabric, then coated by acrylic acid copolymer liquid.

Characteristics: Good alkaline-resistance, high stength, excellent alkali and acid resistance, good cohesion, excellent in coating etc.

Uasge: It is widely used in wall reinforce, out side wall heat insulation, roof waterproof, reinforcement, plastic, bitumen, plaster, marble, mosaic. Etc. It is an ideal engineering material in construction.

Our best quality ablity:

1) mesh of warp and wet mesh is very straight

2)coating enough alkaline resistant glue and keep 60%-80% strength after testing in NaOH 28 days later

3)Made by C-glass or E glass fiber roving as basis material and then treated with acrylic acid coplolymer liquid.

4) our factory is the largerst fiberglass mesh manufacurer in China and the first Chiese factory which open fiberglass mesh factory in Dubai, UAE. In Chinese factory, there are more than 300 sets of textile machie and 8 sets of coating machines, every month we can produce more than 6000000 m2 fiberglass mesh. Dubai factory can produce more than 2000000 m2 every month

5) Dubai fiberglass mesh factory open in Dubai since 2012 year, no ant-dumping tax for europen countries, the quality can reach EU quality standard.

Specification:

Weight: 45G/M2 --350G/M2

Weight: 45g/m2 3*3mm, 60g/m2 5*5mm, 60g/m2 3*3mm, 75g/m2 3*3mm, 80g/m2 5*5mm, 110g/m2 5*5mm, 110g/m2 10*10mm, 120g/m2 10*10mm, 130g/m2 5*5mm, 4*4mm, 145g/m2 4*4mm, 5*5mm, 4*5mm, 160g/m2 4*4mm, 4*5mm, 5*5mm, 190g/m2 4*4mm, 300g/m2 4*4mm, 400g/m2 4*4mm

Mesh size: 3*3mm, 4*4mm, 4*5mm, 5*5mm, 10*10mm

Color: White, blue, green, yellow, red

Width: 15cm --200cm

Roll length: 10m--500m

Fiberglass mesh, alkali resistant fiberglass mesh is on the basis of alkali-resistant or C-glass or E-glass woven fabric, then coated by acrylic acid copolymer liquid.

Characteristics: Good alkaline-resistance, high stength, excellent alkali and acid resistance, good cohesion, excellent in coating etc.

Uasge: It is widely used in wall reinforce, out side wall heat insulation, roof waterproof, reinforcement, plastic, bitumen, plaster, marble, mosaic. Etc. It is an ideal engineering material in construction.

Our best quality ablity:

1) mesh of warp and wet mesh is very straight

2)coating enough alkaline resistant glue and keep 60%-80% strength after testing in NaOH 28 days later

3)Made by C-glass or E glass fiber roving as basis material and then treated with acrylic acid coplolymer liquid.

4) our factory is the largerst fiberglass mesh manufacurer in China and the first Chiese factory which open fiberglass mesh factory in Dubai, UAE. In Chinese factory, there are more than 300 sets of textile machie and 8 sets of coating machines, every month we can produce more than 6000000 m2 fiberglass mesh. Dubai factory can produce more than 2000000 m2 every month

5) Dubai fiberglass mesh factory open in Dubai since 2012 year, no ant-dumping tax for europen countries, the quality can reach EU quality standard.

Specification:

Weight: 45G/M2 --350G/M2

Weight: 45g/m2 3*3mm, 60g/m2 5*5mm, 60g/m2 3*3mm, 75g/m2 3*3mm, 80g/m2 5*5mm, 110g/m2 5*5mm, 110g/m2 10*10mm, 120g/m2 10*10mm, 130g/m2 5*5mm, 4*4mm, 145g/m2 4*4mm, 5*5mm, 4*5mm, 160g/m2 4*4mm, 4*5mm, 5*5mm, 190g/m2 4*4mm, 300g/m2 4*4mm, 400g/m2 4*4mm

Mesh size: 3*3mm, 4*4mm, 4*5mm, 5*5mm, 10*10mm

Color: White, blue, green, yellow, red

Width: 15cm --200cm

Roll length: 10m--500m

Package:

Inner packing: Plastic bag or shrink film

Outer packing: Export carton or pallet

- Q: A brief introduction to glass cloth of glass fiber cloth

- The continuous strand felt is formed from the glass filament in the drawing process or from the original filament cylinder, and the continuous filament is 8 in shape. It is deposited on the continuous moving mesh belt and bonded by powder binder. The fiber in continuous glass fiber felt is continuous, so its strengthening effect on composites is shorter and the felt is good. Mainly used in pultrusion, RTM, pressure bag and glass mat reinforced thermoplastics (GMT) and other processes.

- Q: The difference between glass wool and mineral wool insulation

- Glass wool is generally used less than 200 degrees Celsius heat insulation parts, used for general insulation building or low temperature pipe, rock wool is generally used in thermal insulation parts temperature 500 degrees Celsius, for high temperature heat pipe insulation or power equipment.

- Q: Interior mesh is same to the exterior?

- The price is not same. Interior wall is generally 0.58 yuan per meter; the aperture is 0.6; external wall is 120 g; 0.77 yuan per meter; 130 grams 0.82 yuan; 140 g 0.87; 160 grams 1.12 yuan per meter

- Q: What do medium soft and medium hard mean in fiberglass mesh?

- The softer it is, the better material is. Fiberglass mesh is based on glass fiber woven fabric and formed by alkali-resistant coating.

- Q: How long is a roll of mesh specially for external wall thermal insulation?

- A roll of standard alkali-resistant fiberglass mesh is 100 meters. Some mesh may be only 70 or 80 meters because the manufacturers want instant interests.

- Q: What coats are used in alkali-resistant glass fiber Mesh?

- Exterior paints are available. Mesh reacts with plaster cracking resistant mortar altogether, the coating is done on a plaster.

- Q: Why is it required to wrap alkali-resistant fiberglass mesh at the entrance to the hole?

- Flanging is good for protecting the edge of insulating layer and door and window are vulnerable to external damage. The window and door openings and other locations are not the continuation of the mesh position, large wall decapitated need Internet Plaid lap, discrete locations Mesh prone to stress concentration cracks,

- Q: When the wall plastering, can use galvanized steel mesh instead of alkali glass fiber mesh cloth?

- It's too expensive. It's wasteful and bad to handle.

- Q: Rock wool board insulation, why add two layers of glass fiber network, and XPS is a layer?

- Yes, that's right. Do two layers of mesh cloth to increase the thickness of the surface layer, improve the anti cracking performance and prevent the rainwater from seeping in. We are now doing a rock wool insulation is done: rock wool board full sticky paste, wire mesh hanging in the 50*50 rock wool board, and fixed with anchor bolt, with glazed hollow bead insulation mortar leveling (20mm thick) coated on the surface of the mortar, the middle laying a layer of mesh cloth. The advantage of this method is that the surface smoothness is good, and the anti cracking effect is good. It can prevent the rainwater from entering and make the rock wool soak.

- Q: Who knows how to use glass?silk mesh?

- Before paving, the wall should be cleaned up, potholes should be patched, an then brush latex and pave meshes on the wall, meshes should be paved smoothly, the interval overlap should be at least 50MM. when the wall is wholly dried up, then move on with next step.

Send your message to us

Laticrete Fiberglass Mesh Tape - 60g Fiber Glass Mesh Cloth

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords