Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1.2

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF

FOB Price of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF US $0.198 / Square Meter

MOQ of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF: 10000 Square Meters

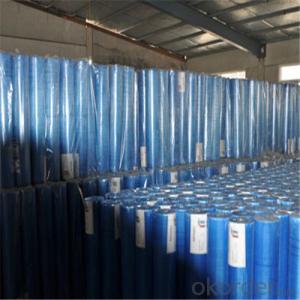

Supply Ability of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF: 6000000 Square Meters per Month

Payment Terms of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF: L/C,T/T

Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF

Specifications of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF

Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF Place of Origin: China (Mainland)

Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF Brand Name: CMAX

Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF Application: Wall Materials

Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF Width: 1M-2M

Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF Size: 5*5/ INCH

Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF Weight: 40gsm to 200gsm

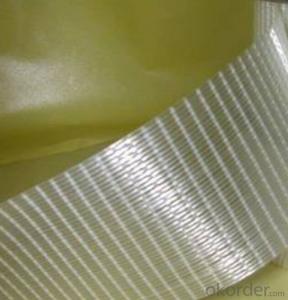

Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF Weave Type: Plain Woven

Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF Yarn Type: C-Glass

Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF Alkali Content: Medium

Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF Standing Temperature: 500℃

Product information of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF

Name: Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF

Use best fiberglass yarn and best glue

Clear and beautiful Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF

High strength Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF

30 years experience of manufacturing Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF

Excellent Priced Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF

FAQ of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF

Q: What is Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF?

Coated Alkali-resistant Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF?

Weight: 135g Width: 0.2M--2M

Length: 20m, 50m, 100m

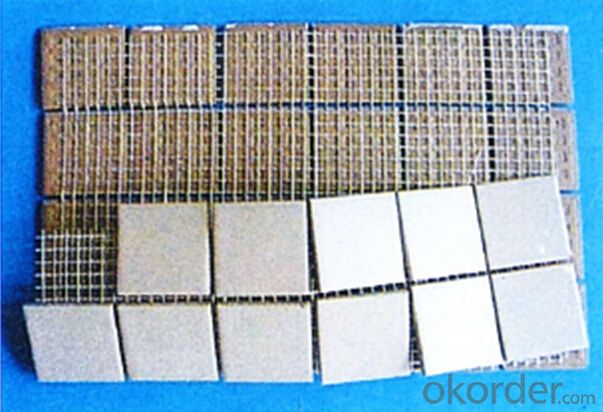

Q: What is the application of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF?

Marble slab reinforcement / Mosaic carrier

Q: What is the storage of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF?

Four years under normal weather conditions and use .

Q: What is the package of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF?

Production periods: 30days for 1X40HQ.

- Q: Does it is required to paste mesh in which has ben pasted with wallpaper?

- Otherwise, the later wall cracks will also affect the wallpaper. Now, the walls has been re-covered with cement. Intend to shovel all red bricks and then cover cement.

- Q: External thermal insulation is using alkali-resistant mesh: does the fracture stress is the same with breaking elongation

- confirming the node has the potentiation to the tensile breaking strength of mesh, analyzing the influence factor to the alkali resistant breaking strength; measuring and testing the node strength of the mesh. from the test result we know that the alkali resistant coating has a certain reinforcement to the mesh tensile breaking strength. through the comparison of the the alkali resistant coating mesh soaking in the alkali resistant mesh alkali liquor, and the alalysis of the SEM atlas and the test of the tensile breaking strength, the friction force of the fibers and the quality of alkali resistant coating surface. the mesh alkali resistant tensile breaking strength is mainly determined by the glass fiber tensile breaking strength.

- Q: What is specification for alkali-resistant fiberglass mesh?

- There are three kinds of alkali-resistant fiberglass mesh, different types have different specification. One, interior wall thermal insulation fiberglass: Mesh: 5mm * 5mm, 4mm * 4mm Weight:80g --- 165g /㎡. Width: 1000mm ---- 2000mm. Length:50m-300m. Second, the external walls thermal insulation mesh. Size: 5x5mm, 4x5mm or 4x4mm. Weight per square: 80g - 160g. Length: 50m, 100m or 200m. Width: 1m - 2m. Three, GRC reinforced mesh. Mesh size: 8mm × 8mm10mm × 10mm12mm × 12mm. Width: 60 cm, 90 cm, or 1 meter. Weight per square : 125g. Length: 100 m or 50 m

- Q: Balcony gauze nets, in the end to buy glass fiber yarn net or 304 stainless steel yarn net?. What are the advantages?

- Of course is a good cheap stainless steel screens and only a few yuan, exposed to the weather not easily broken, good cleaning, side toward the outside is an untouchable, in face of no breakage is not a bit difficult to handle, you can use a dozen or even dozens of years. Fire prevention, rats, bites, etc.Plastic, glass fiber, window screening and so on, even if cheap, every 1-2 years to replace costs and raw materials on the high, but also trouble. For example: even if raw material per square metre 1 yuan, change 10 times raw material is 10 yuan, still do not calculate labor cost.

- Q: What is the tensile strength of glass fiber?

- The melting point of silicon dioxide is very high, in order to achieve this Rongdian is very limited. The ancients had to add some other substances when it becomes low melting temperature. When silica melts down also very obtrusive in the process of heating without gradually filtering transition soft, into some other the material of the glass can be in different temperature range all the splendor, powerful shaping operation and effective setting. This substance is a flux.

- Q: excuse me, when fixing the tile on the external wall of six-floors residential building, the thermal insulation board XPS extruded polystyrene board is using the steel mesh or the glass?fiber mesh.

- it is good to the whole system security and the drawing resistance test of tiles and it should strengthen the XPS plastering mortar and the XPS bond then paste the tile. Using anchor bolt to fix the steel mesh and then paste tiles, then you can carry the force of the anchor to the base wall, a portion of the additional shear and I suggest taking the method of anchor bolt expansion steel mesh.

- Q: Mesh and fiberglass mesh, are they the same?

- They are basically the same, but they just have different names. You can use only one-layer mesh.

- Q: What are the differences between rubber modified asphalt polyester felt, fiberglass mesh waterproof roll and high polymer modified asphalt waterproof coiled material?

- The former belongs to the low-end waterproof materials, used for projects of low waterproof?grade while the latter is quality, belonging to advocated new waterproof material.

- Q: What are the types of glass fiber gridding cloth?

- Specifications for gridding cloth for external walls: 70-160/g. Gridding cloth for external walls is featured by low cost, messy layout, high resistance to alkali, corrosion and cracking, easy construction. It is used for strengthening cement plaster wall.

- Q: What is the glass fiber board?

- Advantages and applications of glass fiber reinforced plastic sheet: glass fiber reinforced plastic board has higher mechanical and dielectric properties, better heat resistance and moisture resistance, and has good processability. Mainly used in plastic mold, injection mold, machinery manufacturing, forming machine, drilling machine, injection molding machine, motor, PCB.ICT fixture, table grinding pad.

Send your message to us

Marble Backing Mesh, 56g/m2, 2mm*4mm, BASF

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1.2

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords