Redgard Fiberglass Mesh Tape - Reinforced Fiberglass Mesh

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m2 m²

- Supply Capability:

- 1x40HQ Per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

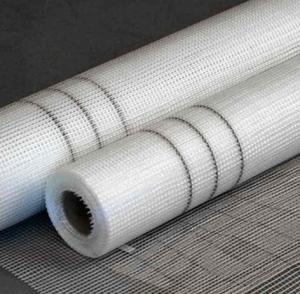

Specifications of Fiberglass Mesh

Fiberglass mesh is mainly alkali-resistant fiberglass fabric, it use the C /E-glass fiber yarn (main ingredient is a silicate, good chemical stability) through a special weaving technique, then by the anti-alkali and reinforcing agent etc high temperature heat finishing treatments. It's an ideal engineering material in construction and decoration industry.

Mesh size: 5mm x 5mm, 4mm x 4mm, or 4mm x 5mm

Weight/m2: 45g-160g

Length/roll: 50m-100m

Width: 1m

Color: white, blue, orange or other colors

Special spec can be ordered and produced by the requirements of customers

Usage/Applications of Fiberglass Mesh

1. Wall reinforced material (such as fiberglass wall mesh, GRC wall panels, EPS insulation with the wall board, gypsum board, bitumen etc)

2. Reinforced cement products.

3. Used for Granite, mosaic, marble back mesh etc.

4. Fabric waterproof membrane, asphalt roofing.

5. Framework material for einforced plastics, rubber products,.

6. Fire board.

7. Grinding wheel base fabric.

8. Road surface with geogrid.

9. Construction caulking tape etc.

Packaging & Delivery of Fiberglass Mesh

Packaging: Each roll is shrink-wrapped, or to be packed in plastic bag. Then rolls are put into pallets and cartons.

Delivery: About 25 days after confirming the order.

Characteristics of Fiberglass Mesh

1. Good chemical stability: Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemicals' corrosion resistant; and strong resin bonding, soluble in styrene.

2. Outstanding craftsmanship include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after test in Naoh 28days later, so that guarantee high strength, high tensility, light weight.

3. Our fiberglass yarn is supplied by Jushi Group which is the largest producer of fiberglass yarn in the world like Saint Gobain, it's 20% extra strong strength and beauty surface than normal fiberglass yarn.

4. Strength retention rate> 90%, elongation <1%, the durability of more than 50 years.

5. Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property.

6. Good impact resistance and not easy to be teared.

- Q: What kind of wall fabric is covered with fiberglass mesh? Do you apply the powder or the powder?

- Most of the fiberglass mesh is used for the powder, but also outside powder, but at present there is no domestic how expensive, too expensive!

- Q: How to DIY the setting adhesive of glass fiber gridding cloth?

- With glass fiber woven fabric as base material, gridding cloth is dipped in and coated with highly resistant polymer emulsion, thus featured by good alkali resistance, flexibility and high tensile resistance in the bidirection of warp and weft. It is widely used for thermal insulation, water proofing and crack resistance of internal and external walls of buildings. The glass fiber gridding cloth mainly adopts alkali glass fiber yarn (with silicate, stability as main components) and made by high-temperature heat setting such as anti alkali liquid and strengthening agent of the special organization structure - lace stitch.

- Q: Is the diamond screen good or invisible or traditional screen?

- Contact: transparent zero line of sight blocking, zero distance visual communication with the outside world, 24 hours a day to maintain the natural fresh air circulation, reduce health caused by air conditioning, let you and your family will always be healthy.

- Q: Soft or hard glass fiber gridding cloth used for walls, which is better?

- It depends on the quality. Generally the price of gridding cloth for external wall is 1 yuan/㎡.

- Q: The original walls have been posted withmesh. Now the quality is very good without drum kits and cracking, is it neccessary to be removed when decorating?

- There is no need. If you want to paste the wallpaper, you don't need to remove it and the painting of the wall is also not needed.

- Q: When plastering walls, can alkali-resistant fiberglass mesh be replaced by galvanized steel mesh?

- Before puttying in the stage of decoration, alkali-resistant fiberglass mesh is used to prevent the surface putty from cracking. The price is too large. When the plasterign thickness is equal to or more than 35mm, galvanized?steel?mesh is needed. It wastes too much and it's not easy to operate. Galvanized steel mesh is generally used in the stage of cement mortar whitewashing wall.

- Q: Does it need to whitewash while pasting fiberglass mesh of wall plastering?

- Before whitewashing the bottom ash, it had better to spray a prime interface agent to increase adhesion.

- Q: Why is it required to wrap alkali-resistant fiberglass mesh at the entrance to the hole?

- Flanging is good for protecting the edge of insulating layer and door and window are vulnerable to external damage. The window and door openings and other locations are not the continuation of the mesh position, large wall decapitated need Internet Plaid lap, discrete locations Mesh prone to stress concentration cracks,

- Q: How to choose glass fiber gridding cloth for thermal insulation of internal and external walls?

- It depends on metope need. General speaking, gridding cloth is used due to its crack resistance.

- Q: How to clean fiberglass mesh?

- It needn't to be cleaned.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Redgard Fiberglass Mesh Tape - Reinforced Fiberglass Mesh

- Loading Port:

- SHANGHAI Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m2 m²

- Supply Capability:

- 1x40HQ Per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords