Manta Geotextil Sika Woven Monofilament Geotextile for Construction Companies

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

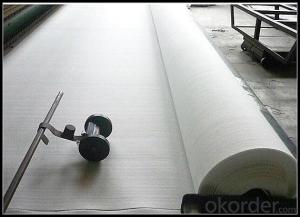

Woven geotextiles consist of monofilament, multifilament, slit-film and/or fibrillated

slit-film yarns - often in Woven geotextiles Image combinations - that are woven into a

geotextile on conventional textile weaving machinery using a wide variety of traditional,

as well as proprietary, weaving patterns. The variations are many and most have a direct

influence on the physical, mechanical and hydraulic properties of the fabric. The

resulting woven geotextiles are typically flexible, exhibit high strength, high modulus,

low elongation, and their openings are usually direct and predictable.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

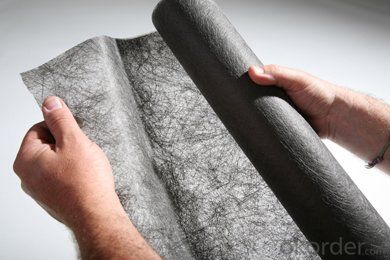

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is geotextile cloth?

- Geogrid, geotextile, geomembrane manufacturers, specializing in the production

- Q: How do geotextiles affect soil compaction?

- Geotextiles can help reduce soil compaction by acting as a barrier between the soil and external forces. They distribute load and stress more evenly, preventing excessive compaction by promoting better soil structure and drainage.

- Q: Geosynthetics direct shear instrument reference standards which

- ISO.1, GB / T.1, ASTMD5321, JTGE50T1129, BiaozhunJiTuan-2017, SL / T235-1999. hope this helps.

- Q: Can geotextiles be used in mine tailings dewatering applications?

- Yes, geotextiles can be used in mine tailings dewatering applications. Geotextiles provide filtration and separation functions, allowing for efficient dewatering of mine tailings by separating solids from liquids. They can help in reducing the moisture content of the tailings, making them easier to handle and manage. Geotextiles also aid in improving the stability and strength of the dewatered tailings, minimizing the risk of slope failures or environmental contamination.

- Q: How do geotextiles aid in the reduction of soil settlement?

- Geotextiles aid in the reduction of soil settlement by providing a separation layer between two soil layers, preventing intermixing and consolidation. This separation minimizes the migration of fine particles and water, maintaining the stability and integrity of the soil layers, ultimately reducing settlement.

- Q: How to determine the nominal breaking strength of filament spunbonded nonwoven geotextile

- You can use a dedicated geotextile strong test machine detected.

- Q: Can geotextiles be used in canal lining projects?

- Yes, geotextiles can be used in canal lining projects. Geotextiles are commonly used to provide stability, reinforcement, and filtration in various civil engineering projects, including canal lining. They help to prevent erosion, control water flow, and enhance the overall performance and durability of the canal lining system.

- Q: I'm looking for the fabric that goes between gravel and the ground (for a gravel driveway).

- any good irrigation/ landscape suply house will have that material.

- Q: Can geotextiles be used in dam construction?

- Yes, geotextiles can be used in dam construction. Geotextiles are commonly used as a part of the filter and drainage system in dam construction projects to enhance stability, prevent soil erosion, and improve overall performance of the structure. They can help manage water flow, reinforce the soil, and provide long-term protection against erosion and piping.

- Q: Can geotextiles be used in the protection of underground tanks?

- Yes, geotextiles can be used in the protection of underground tanks. Geotextiles are commonly used as a protective layer to prevent damage to underground tanks from surrounding soil movement or external pressure. They provide an effective barrier between the tank and the surrounding soil, reducing the risk of punctures, abrasions, and corrosion. Additionally, geotextiles can help with filtration and drainage, ensuring proper functioning and longevity of the underground tank.

Send your message to us

Manta Geotextil Sika Woven Monofilament Geotextile for Construction Companies

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords